Construction method of prestressing force fiber cloth reinforcing column adopting detachable tensioning anchorage device

A construction method and fiber cloth technology, which are used in bridge reinforcement, building maintenance, bridge maintenance, etc., can solve the problem that the prestress value of the fiber cloth does not reach the expectation, the bending deformation of the clip or the roller is large, and the tension anchor is not repeatable. Use and other problems to achieve the effect of convenient operation, increase friction, and avoid slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

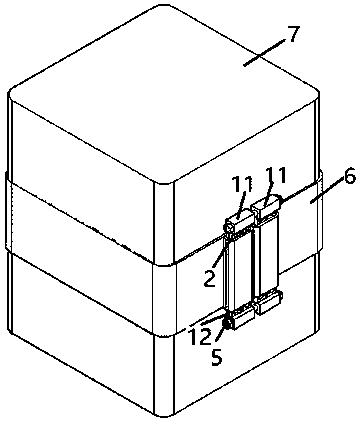

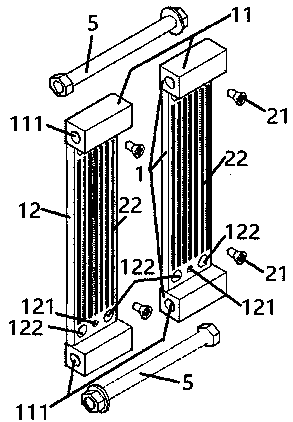

[0034] Such as figure 1 , 2 , 3, 4, 10, 11, 12 and 13, this embodiment takes the reinforced concrete square column 7 as the reinforcement object, and utilizes a detachable prestressed fiber cloth tensioning anchorage device to reinforce it , the width of the fiber cloth 6 is 150mm. Specific steps are as follows:

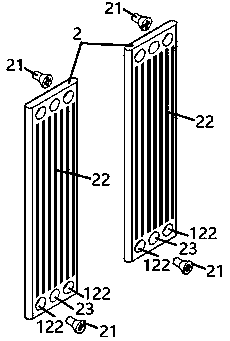

[0035](1) A prestressed fiber cloth tensioning anchoring device with detachable tensioning anchors is provided, which includes two anchor plates 1, two splints 2, two tensioning anchors 3, and two tensioning screws 4 And two anchoring screws 5 and fiber cloth 6 for maintaining the prestress; the anchor plate 1 is composed of the anchor plate anchor head 11 and the anchor plate body 12 at both ends of the anchor plate 1, and the center of the anchor plate anchor head 11 at both ends of the anchor plate 1 is parallel to the fiber An anchor screw hole 111 is opened in the wrapping direction of the cloth 6, and an anchor plate installation hole 121 is opened at the ce...

Embodiment 2

[0046] Such as Figure 5-14 As shown, in this embodiment, the reinforced concrete cylinder 8 is used as the reinforcement object, and it is reinforced by a detachable prestressed fiber cloth tensioning anchorage device. The width of the fiber cloth 6 is 150 mm. Specific steps are as follows:

[0047] (1) A prestressed fiber cloth tensioning anchoring device with detachable tensioning anchors is provided, which includes two anchor plates 1, two splints 2, two tensioning anchors 3, and two tensioning screws 4 And two anchoring screws 5 and fiber cloth 6 for maintaining the prestress; the anchor plate 1 is composed of the anchor plate anchor head 11 and the anchor plate body 12 at both ends of the anchor plate 1, and the center of the anchor plate anchor head 11 at both ends of the anchor plate 1 is parallel to the fiber An anchor screw hole 111 is opened in the wrapping direction of the cloth 6, and an anchor plate installation hole 121 is opened at the center of the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com