Connector for vehicle pipeline and vehicle crankcase ventilation pipeline with same

A technology for crankcase ventilation and connecting joints, applied in crankcase ventilation, engine components, machines/engines, etc., can solve problems such as mixed gas leakage, and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

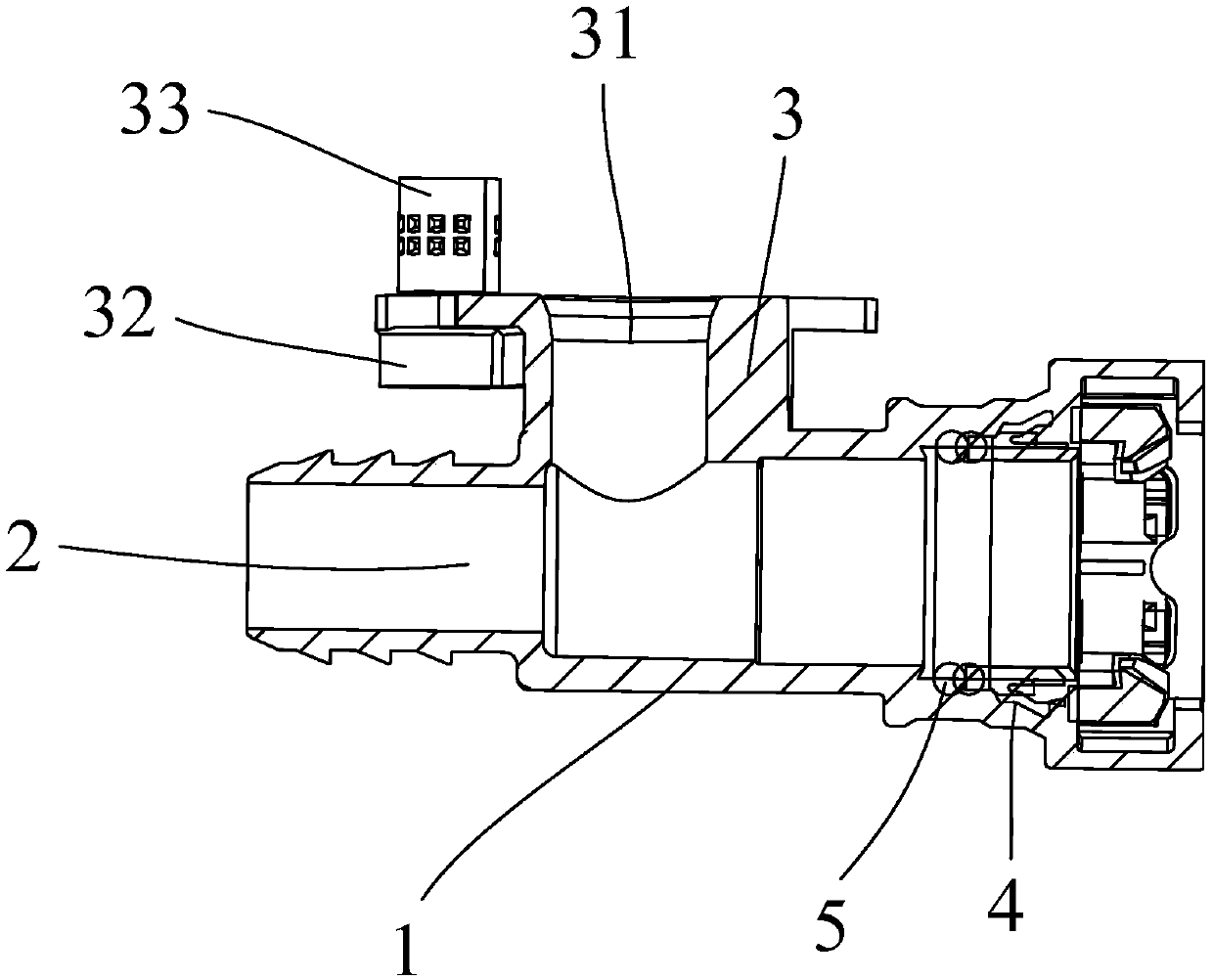

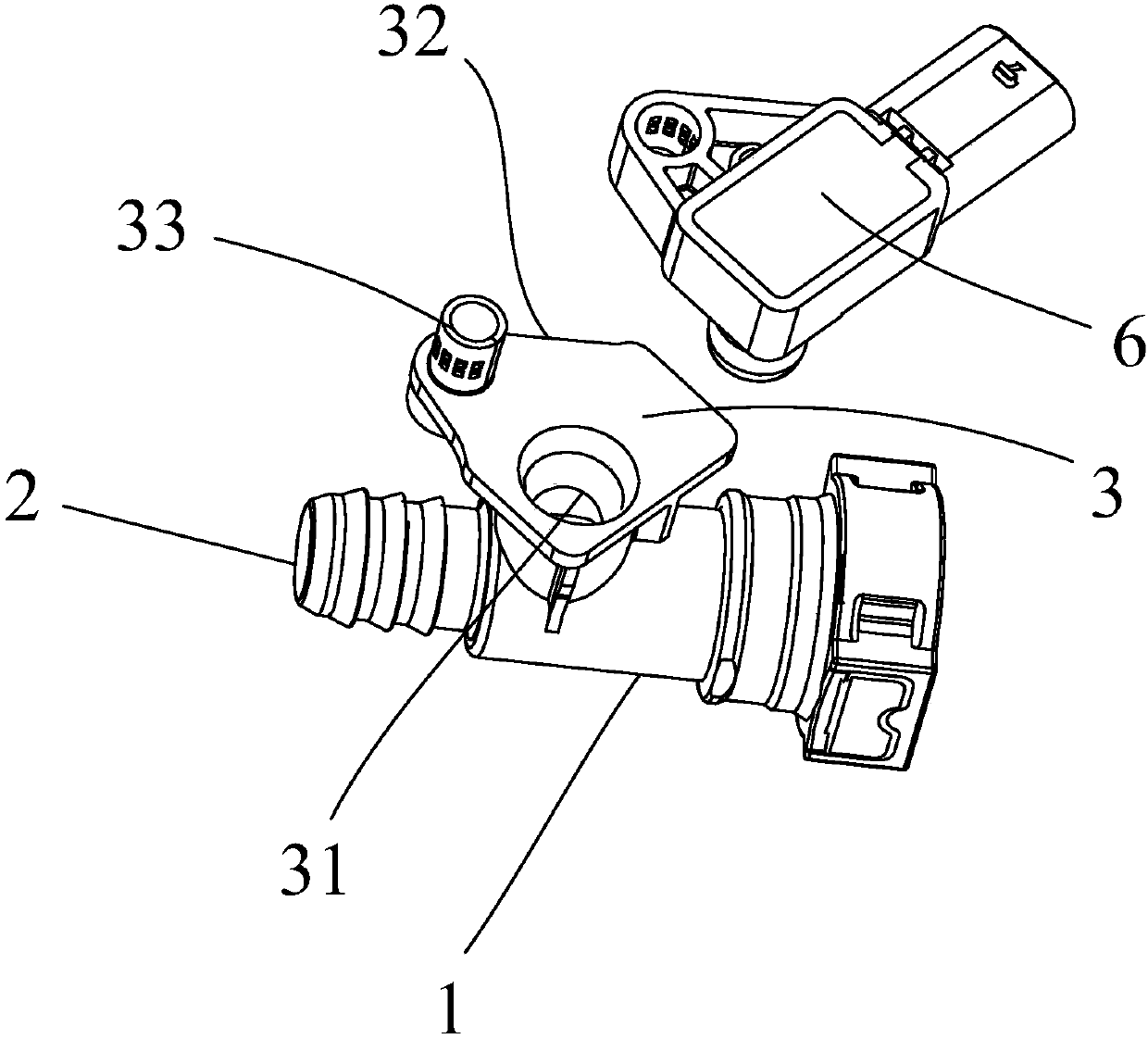

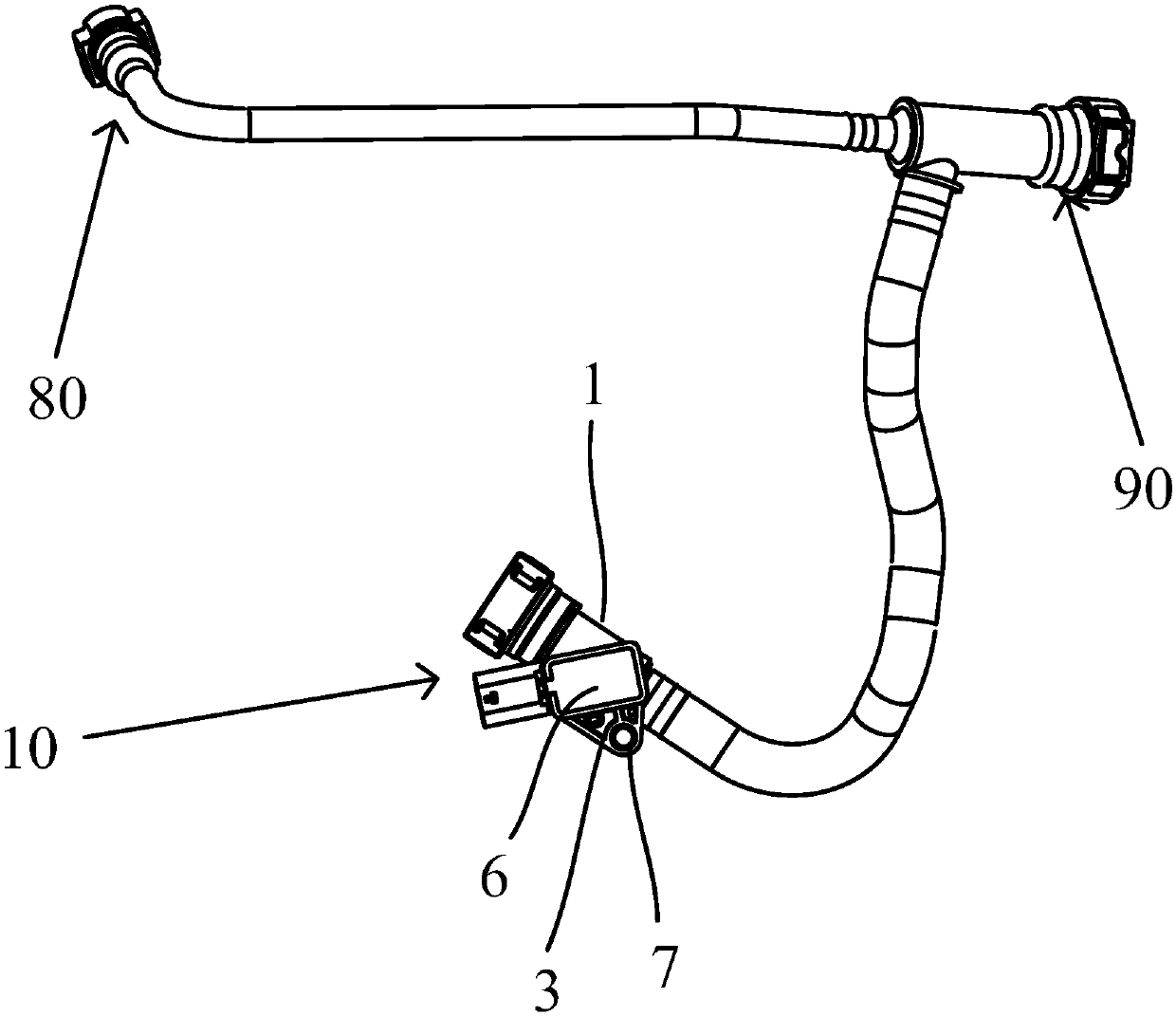

[0020] Such as figure 1 As shown, the vehicle pipeline connection joint of this embodiment includes a joint body 1 and a central hole 2, and the central hole 2 runs through the joint body 1. The vehicle pipeline connection joint also includes a bracket 3, which is located in the middle section of the joint body 1, and the bracket It includes a through hole 31 in the middle and an extension portion 32 surrounding the through hole. The through hole 31 communicates with the central hole 2 . Such as figure 2 As shown, the vehicle pipeline connection joint of this embodiment can be installed in cooperation with the pressure sensor 6 to monitor the pressure change of the mixed gas in the pipeline and prevent leakage.

[0021] Such as figure 1 with figure 2 As shown, the bracket 3 further includes a threaded bush 33 integrally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com