Vortex compressor and air discharging method thereof

A scroll compressor and compression mechanism technology, applied in the field of compressors, can solve the problems of reduced service life of compressors, easy wear of components, complex structure, etc., and achieve the effect of large air output, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

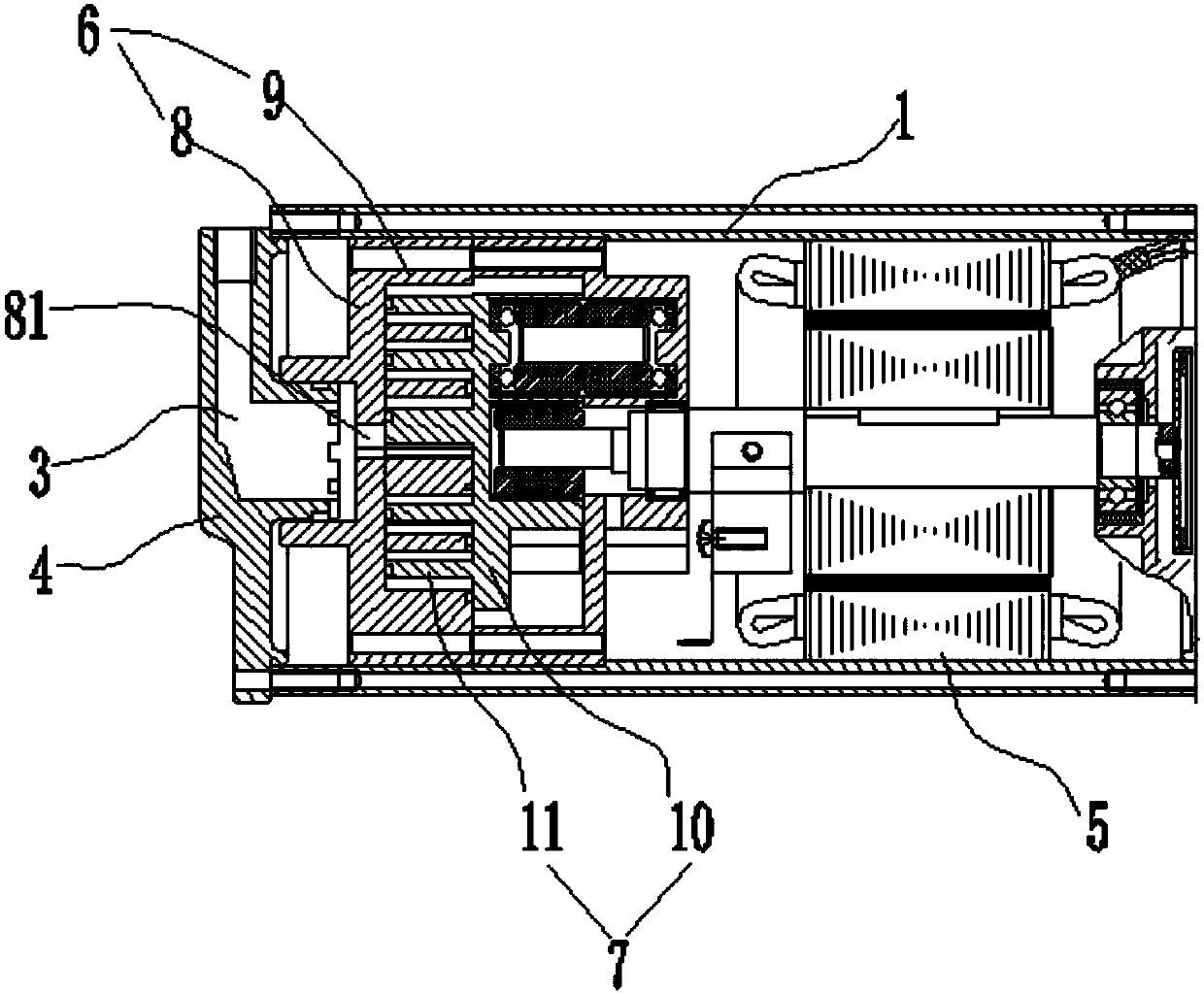

[0048] Such as Figure 1 to Figure 8 As shown, a scroll compressor includes a housing 1, an end cover 4 with an air inlet passage 2 and an air outlet passage 3 located on one side of the housing 1, a power output device 5 arranged in the housing 1, and a The scroll compression mechanism connected to the power output device 5, wherein the power output device 5 is a motor, and the scroll compression mechanism includes:

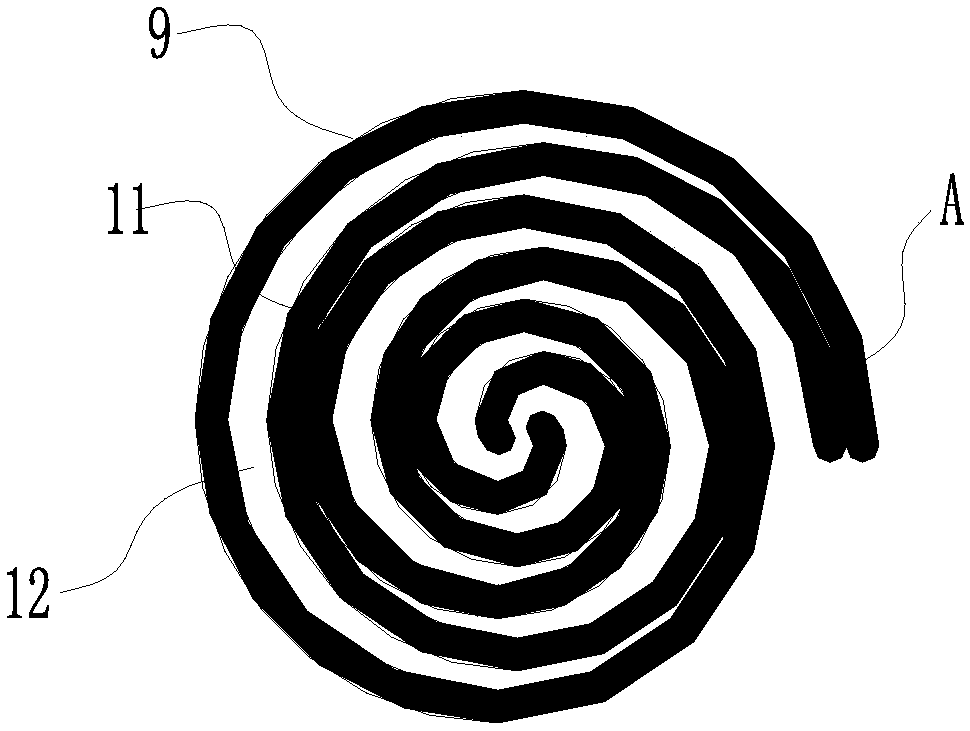

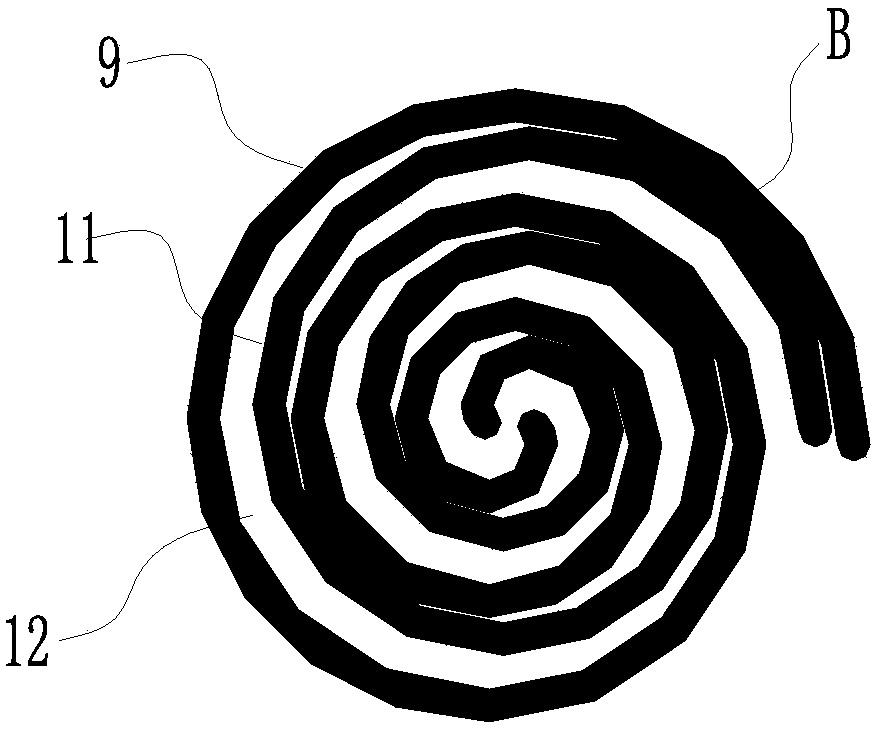

[0049] The vortex stationary disc 6 located on one side of the end cover 4, the vortex motor disc 7 located on one side of the power output device 5 and eccentrically connected with the output shaft of the power output device, the vortex stationary disc 6 is fixed by the stationary plate 8 and the static disk helical sleeve 9, the vortex motorized disk 7 is composed of a moving disk fixed plate 10 and a moving disk helical sleeve 11, the static disk helical sleeve 9 and the moving disk helical sleeve 11 are socketed, the inner wall of the static disk helical sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com