Verification system and method for online monitoring device of onsite capacitive equipment

A technology of capacitive equipment and monitoring devices, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as difficult on-site handling, very long stretching, signal distortion, etc., achieve strong anti-electromagnetic field interference performance, save The effect of line take-up, amplitude and phase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

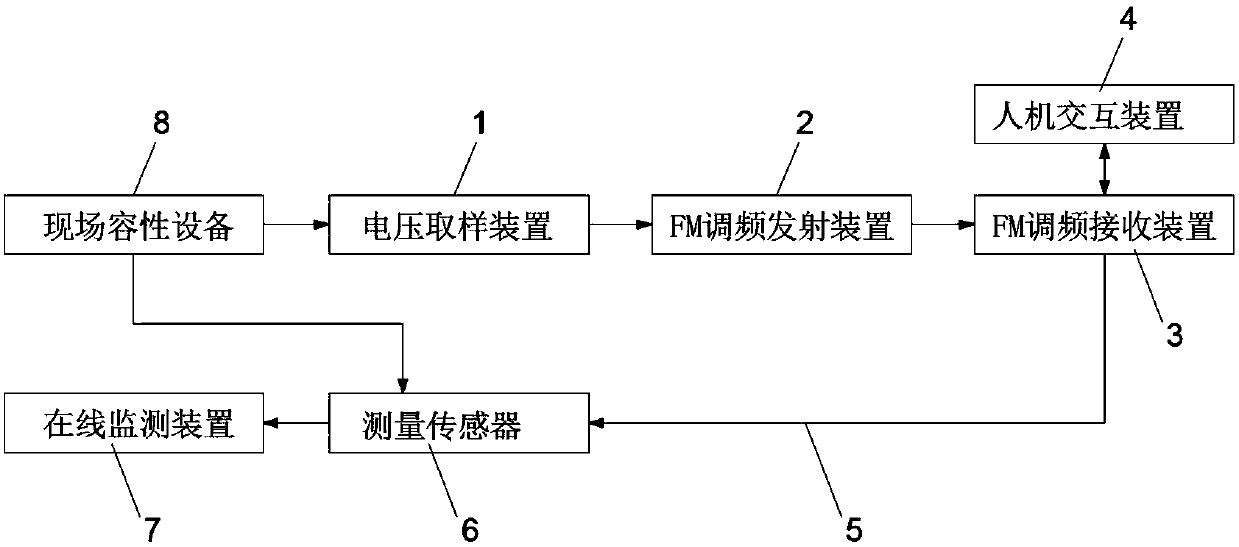

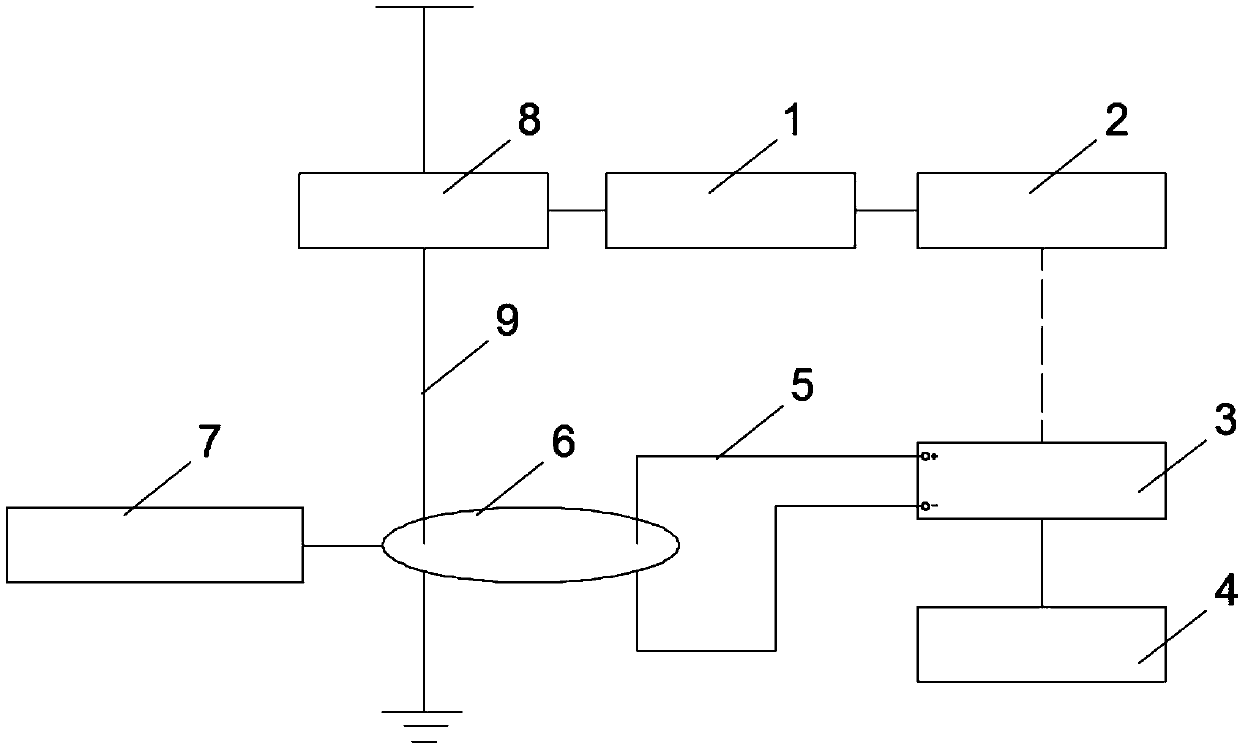

[0043] Such as figure 1 and figure 2 As shown, the verification system of a field capacitive equipment on-line monitoring device provided by the present invention includes a voltage sampling device 1, an FM frequency modulation transmitting device 2, an FM frequency modulation receiving device 3, a human-computer interaction device 4, a current output wire 5 and Measuring sensor6.

[0044] Described voltage sampling device 1 is connected with the voltage input terminal of on-site capacitive equipment 8, is used to obtain the operation reference voltage of on-site capacitive equipment 8, and transmits to FM frequency modulation transmitting device 2, and voltage sampling device 1 is in the present embodiment High precision transformer;

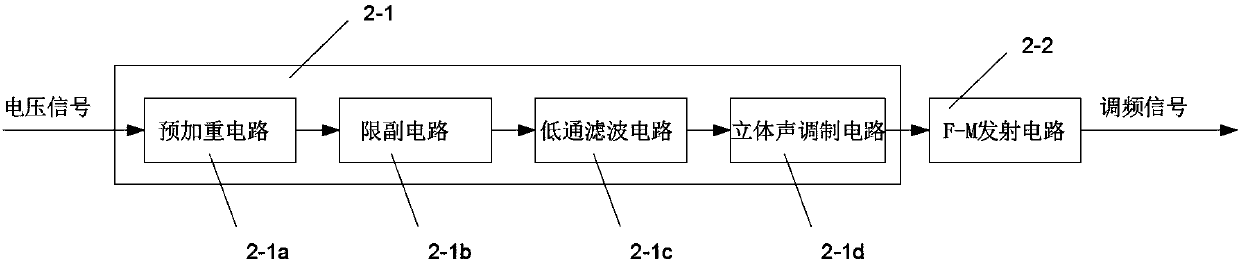

[0045] The FM FM transmitting device 2 is connected with the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com