Modeling and optimization method of cold-end system of direct air-cooled generator set

A technology for generating set and system modeling, which is applied in multi-objective optimization, design optimization/simulation, computer-aided design, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

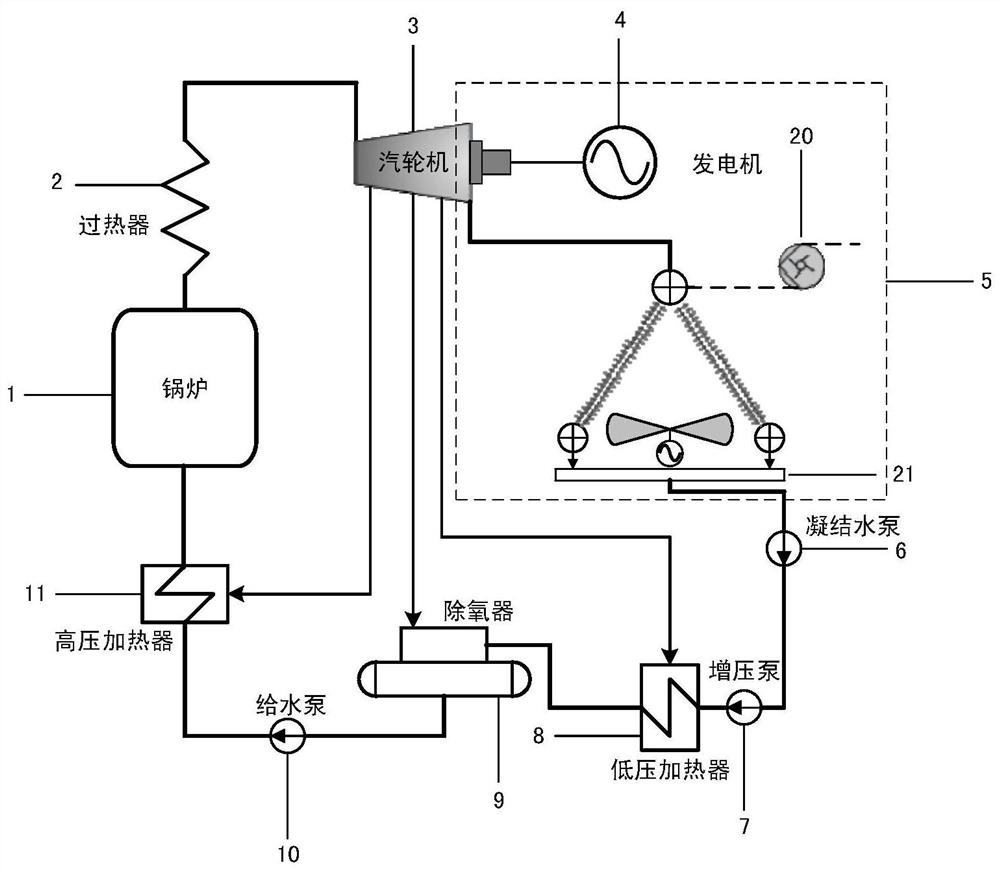

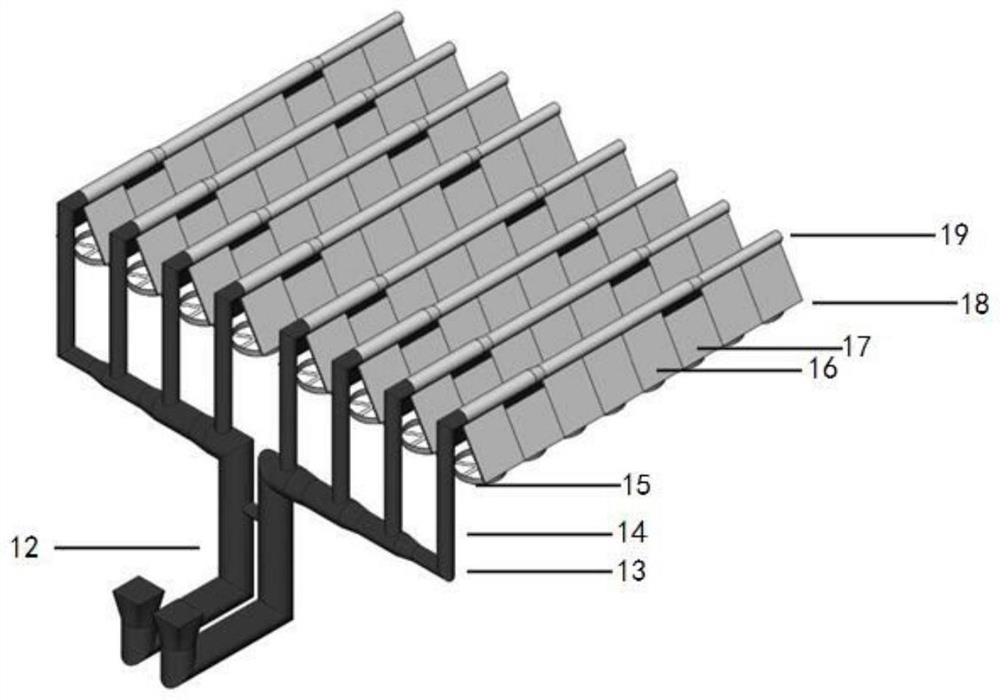

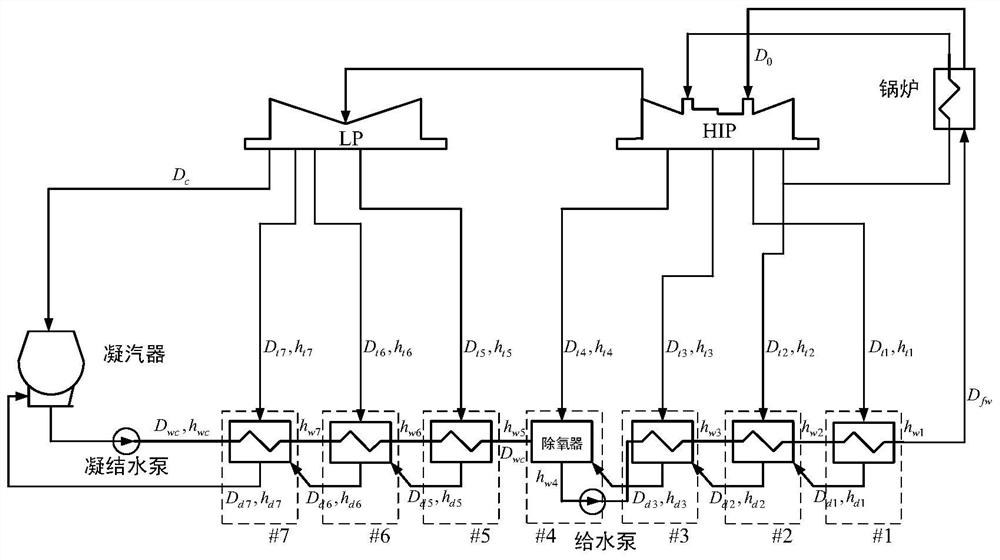

Method used

Image

Examples

Embodiment 1

[0244] Figure 7 shows the dynamic response curve of the dynamic mechanism model of the cold-end system of the direct air-cooling unit of the present invention obtained in Example 1 when the ambient temperature rises stepwise from 293K to 303K. Figure 7(a) is the dynamic response curve of the back pressure of the unit. As the ambient temperature rises, the cooling air temperature rises, the heat exchange between the exhaust steam of the steam turbine and the environment will be weakened, and the steam condensation process in the air-cooled condenser will also be weakened. Uncondensed steam remains in the condenser, causing increased unit back pressure. Figure 7(b) is the dynamic response curve of the steam flow of distribution headers in each column. Due to the increase of unit back pressure, the extraction steam flow of the seventh stage of the steam turbine recuperation system will decrease, and the exhaust steam flow of the steam turbine will increase, resulting in the distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com