Stair full-cycle lean management construction method

A construction method and a full-cycle technology, applied in data processing applications, instruments, resources, etc., can solve problems such as inability to optimize the arrangement of staircase facing materials, difficult allocation and correction of structural construction deviations, and poor handling of finishing details. Achieve the effect of saving materials and labor costs, improving the quality of engineering details, and reducing on-site cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

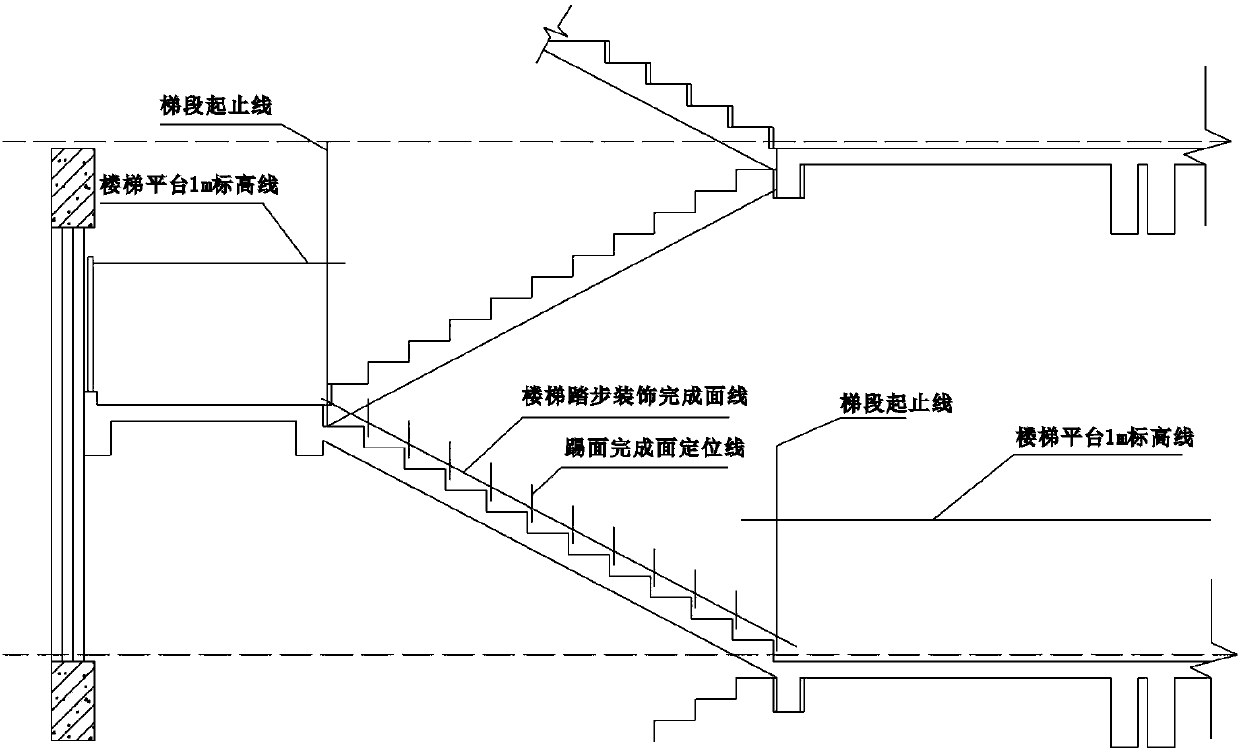

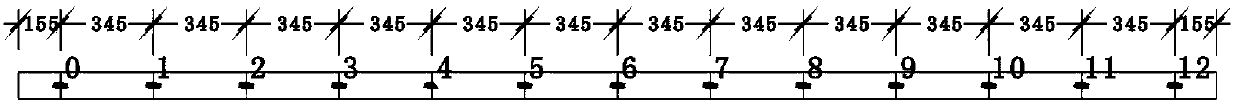

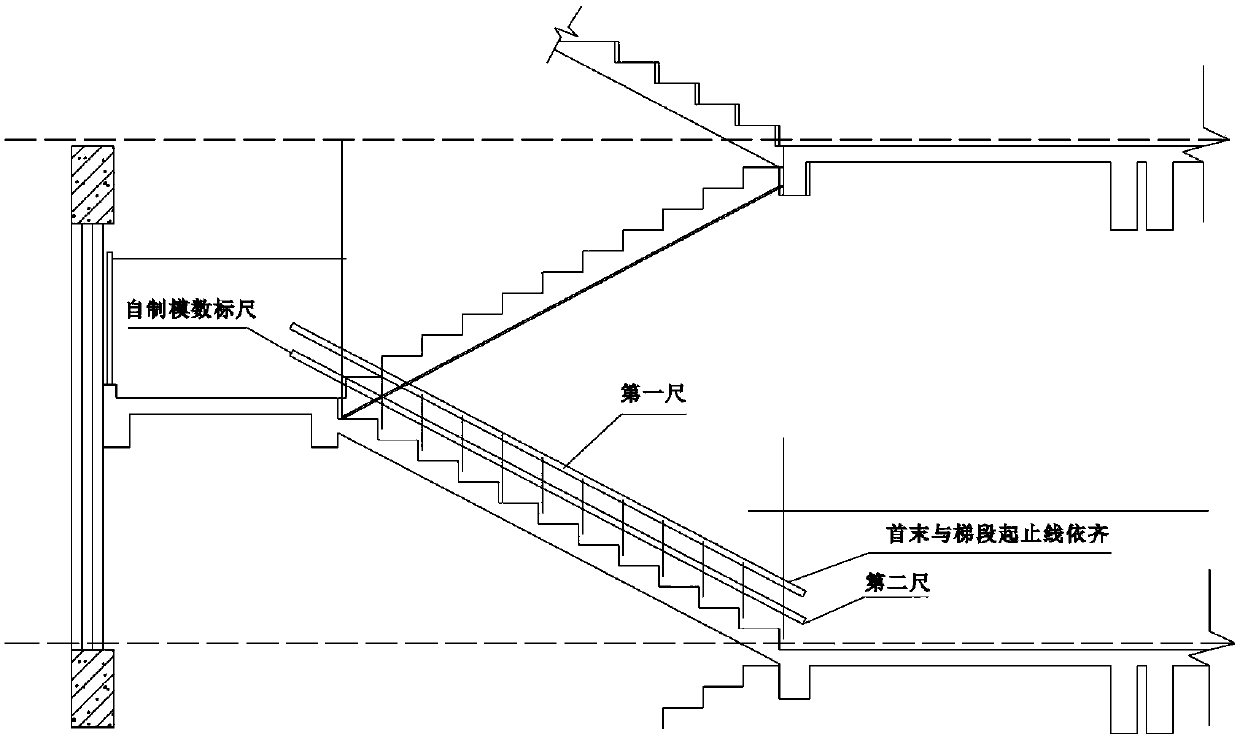

[0042] Such as Figure 1-7As shown, a lean management construction method for the whole cycle of stairs includes the following steps: (1) Determine the facing materials and determine the reserved dimensions of the stairs: first, in the construction preparation stage, read the architectural decoration instructions, and compare the building construction drawings with the structural construction Check the drawings carefully, and review the elevation of the stair platform and the start and end positions of the steps in the structural construction drawings; then, according to the architectural construction drawings, classify and record the facing materials, process types, and stair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com