Straight-through gas purification device

A gas purification device and a straight-through technology, which is applied in the direction of combined devices, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of easy blockage of the filter screen and poor purification effect, so as to avoid low purification efficiency and reduce operation Quantity, efficient and stable effect of purifying gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

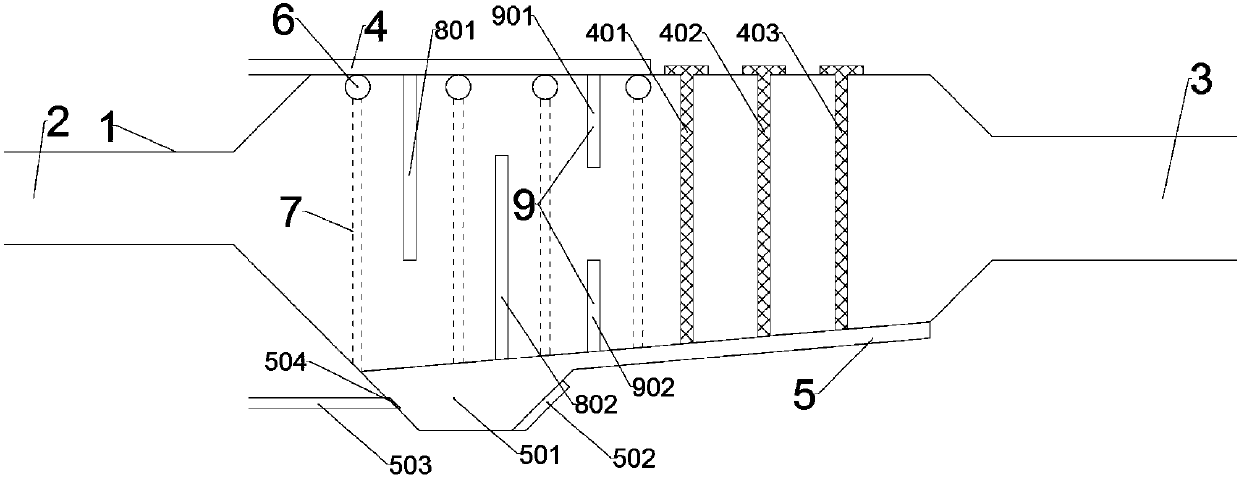

[0030] A straight-through gas purification device, comprising a purifier body 1, an air inlet 2 and an exhaust port 3 are respectively provided at both ends of the purifier body 1, and it is characterized in that an upper end outside of the purifier body 1 is provided with There is a water inlet channel 4, and the inside of the upper end of the purifier body 1 is provided with a nozzle 6 communicating with the water inlet channel 4, and a row of regularly distributed water outlet holes is provided under the nozzle 6, and the inside of the purifier body 1 There are three baffles, namely the first baffle 801, the second baffle 802 and the third baffle 9, and the first baffle 801 is fixed on the inner wall of the purifier body 1. There is a passage for ventilation between the upper part and the lower part of the inner wall of the purifier body 1, and the second baffle plate 802 is fixed on the lower part of the inner wall of the purifier body 1 and is left for ventilation with the...

Embodiment 2

[0033]This embodiment is further optimized on the basis of Embodiment 1. Specifically, two rows of regularly distributed water outlet holes are opened below the nozzle 6, and the number of filter layers is set to three, which are respectively the first filter layer 401, the second filter layer 402 and the third filter layer 403, the pore size of the first filter layer 401 is larger than the pore size of the second filter layer 402, the pore size of the second filter layer 402 is larger than the pore size of the third filter layer 403, the The first baffle 801, the second baffle 802, the third baffle 9, the first filter layer 401, the second filter layer 402 and the third filter layer 403 are distributed in sequence along the direction from the air inlet 2 to the exhaust port 3. The inside of the purifier body 1, and the first filter layer 401, the second filter layer 402 and the third filter layer 403 are connected with the purifier body 1 through a chute, and the drainage groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com