Waterborne wood paint and preparation method thereof

A water-based wood paint and primer technology, applied in the field of latex paint, can solve the problems of high price, easy cracking and wrinkling of paint film, and achieve the effect of low price and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

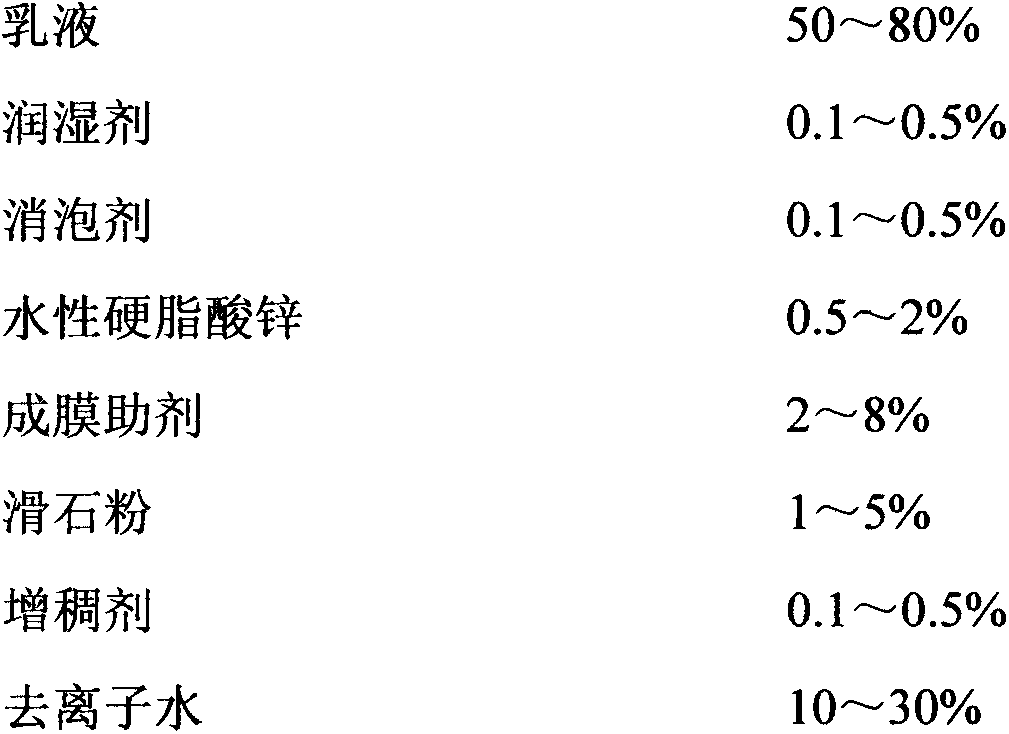

[0020] A kind of water-based wood paint, is characterized in that, primer comprises the following components by weight g:

[0021]

[0022]

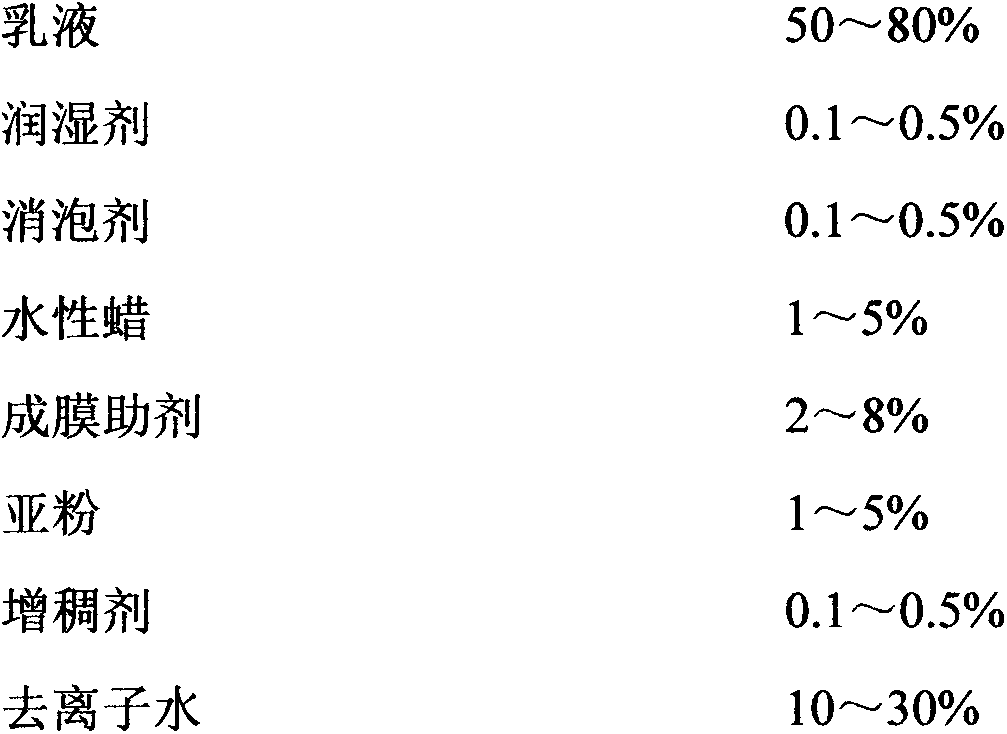

[0023] The topcoat comprises the following components in g by weight:

[0024]

[0025] The preparation method of the wood lacquer, wherein the solid content of the styrene-acrylic emulsion is 40% ± 1, specifically comprises the following steps:

[0026] Pre-mix the emulsion, wetting agent and defoamer, add water-based zinc stearate or water-based wax, film-forming aids and deionized water under stirring at 900-1200 rpm, and then add talcum powder or powder, and finally add an appropriate amount of thickener, stir for 40-50 minutes, and filter.

Embodiment 2

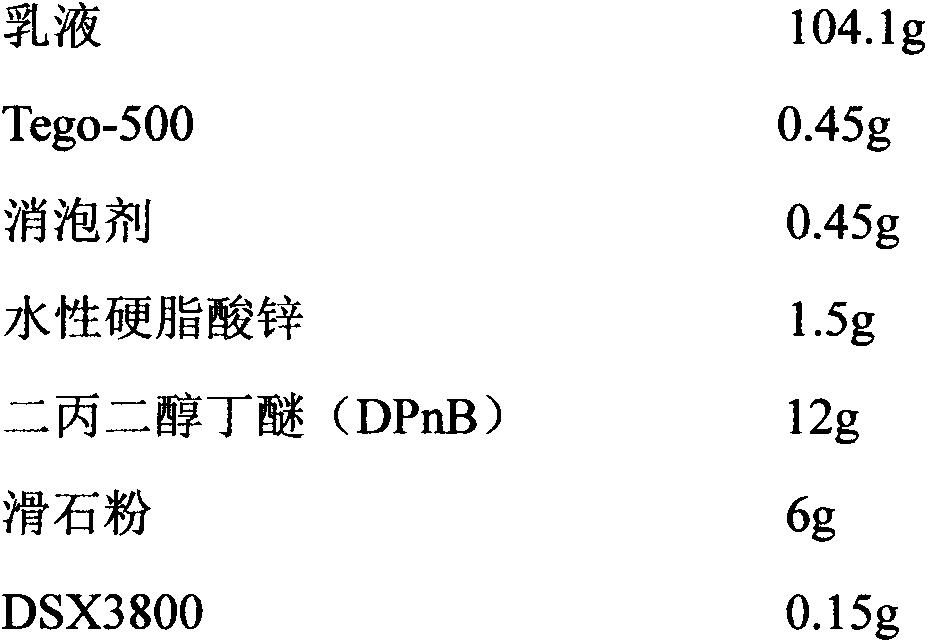

[0028] A kind of water-based wood paint, is characterized in that, primer comprises the following components by weight g:

[0029]

[0030] The topcoat comprises the following components in g by weight:

[0031]

[0032]

[0033] The preparation method of described wood lacquer is with embodiment 1.

Embodiment 3

[0035] A kind of water-based wood paint, is characterized in that, primer comprises the following components by weight g:

[0036]

[0037] The topcoat comprises the following components in g by weight:

[0038]

[0039] The preparation method of described wood lacquer is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com