Assurance method of insulation distance of high-voltage coil

An insulation distance, high-voltage coil technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, transformer/inductor components, etc. Problems such as the increase of breakdown phenomenon, to achieve the effect of easy operation, increase reliability and service life, and reduce arcing and breakdown phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

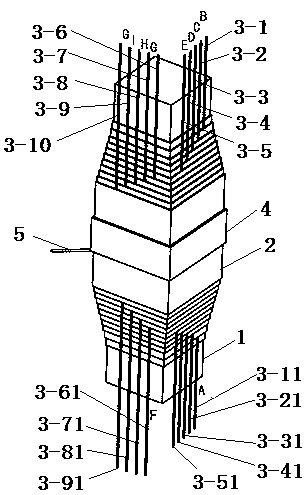

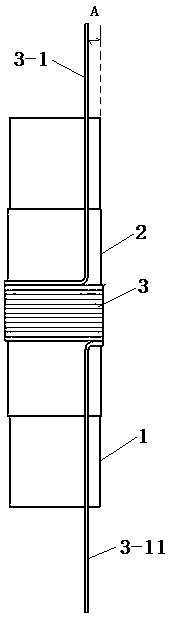

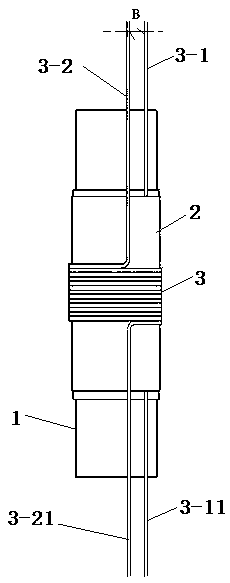

[0038] Such as figure 1 , Figure 13 As shown, a method for ensuring the insulation distance of a high-voltage coil includes a skeleton 1, an insulating film 2, an enameled wire 3, a sleeve, a copper sheet 4, and a lead wire 5.

[0039] The skeleton 1 is a rectangular hollow structure with a square cross section.

[0040] The insulating film 2 is composed of two layers of Noemi paper 2-1 with a high temperature resistant polyester film 2-2 in the middle.

[0041] The steps are as follows:

[0042] The first step is to wind the first layer of wires such as figure 2 As shown, the first layer of insulating film 2 is covered at the middle position of the upper and lower ends of one surface of the skeleton 1, and the first layer of polyurethane enameled wire 3 is wound at the middle position of the upper and lower ends of the first layer of insulating film 2. The first layer starts from I3- 1 and the tail end I3-11 protrude from the upper and lower ends of the skeleton 1 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com