Flux-cored wire gas-shielded vertical upward welding process method

A technology of flux-cored welding wire and process method, which is applied in the direction of manufacturing tools, welding equipment, metal processing, etc., and can solve the problem that it is difficult to realize automatic welding of vertical cylinder thin-walled plates, and it is impossible to realize single-sided welding and double-sided forming, which affects welding quality and efficiency issues, to achieve the effect of improving the degree of docking automation, shortening the construction cycle, and improving welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to deepen understanding of the present invention, below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0026] This embodiment provides a thin-walled plate flux-cored wire gas shielded vertical upward welding process, including the following steps:

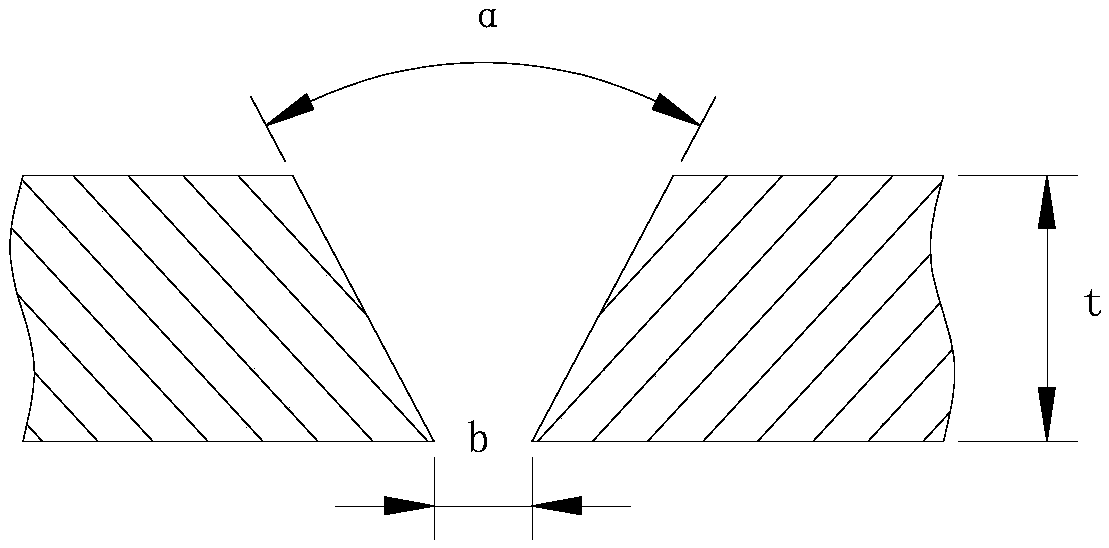

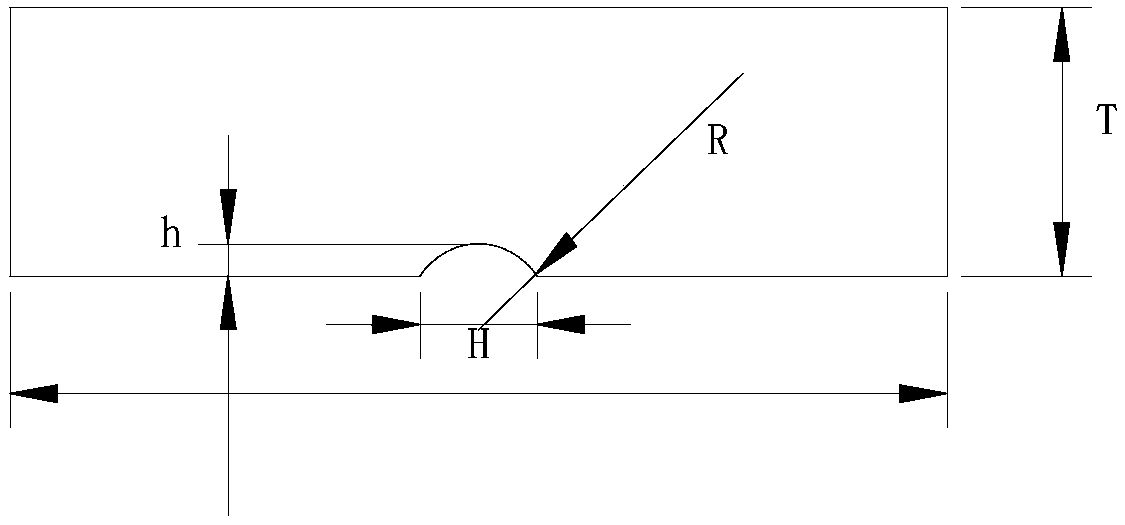

[0027] ① Starting from the butt joint of thin-walled plates in the vertical cylinder project, the wall thickness research range (6-10mm) is selected, and the welding process method of forced forming of self-protected flux-cored wire single-sided water-cooled copper liner is adopted;

[0028] ② Cut and groove the thin-walled plates to be welded by mechanical processing methods, and derust, degrease and decontaminate the thin-walled plates near the bevels;

[0029] ③ The welding process of vertical cylinder thin-walled plates is prone to weld shrinkage, so the anti-deformation is controlled by unequal assembly gaps;

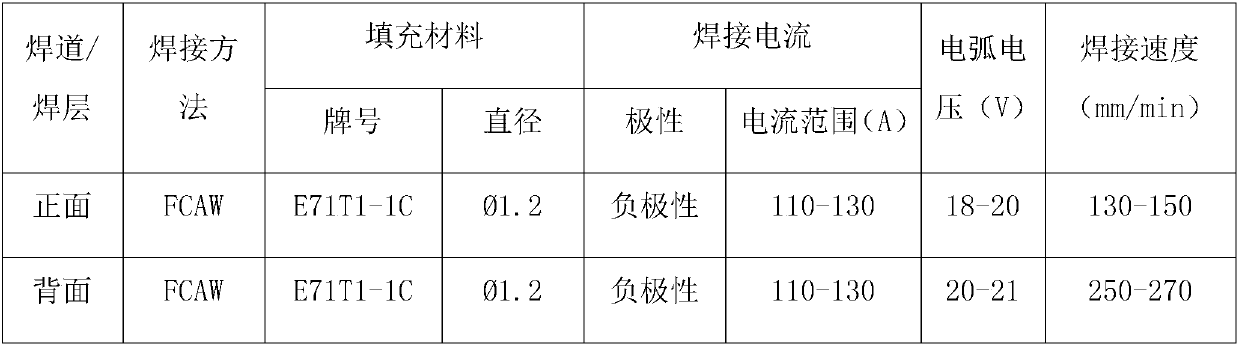

[0030] ④Select welding con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com