Wireless detection device and wireless detection method for welding quality on-line monitoring and man-hour counting

A wireless detection and welding quality technology, applied in the field of wireless communication technology and intelligent detection, can solve the problems of lost data monitoring and statistics, encouragement, inconvenient wired communication, etc., and achieve scientific and reasonable data processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

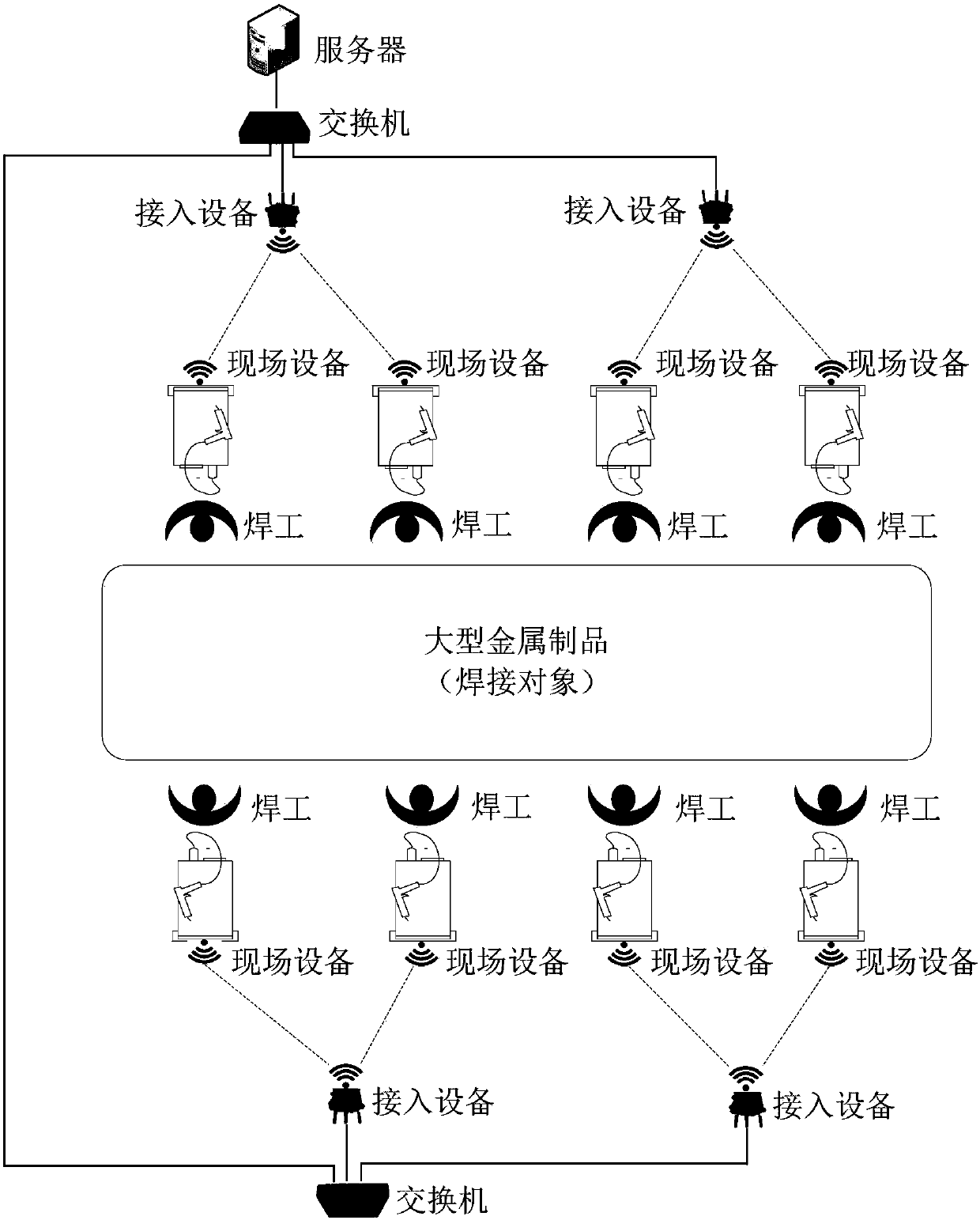

[0047] The device of the invention includes three parts: wireless field equipment, wireless access equipment and upper layer processing software. The invention method and hardware design are universal, and different hardware and specific software implementation methods can be selected according to the actual application environment. This patent provides the hardware selection of a typical device:

[0048] Such as Figure 4 As shown, the wireless field equipment mainly includes switching power supply, voltage stabilization protection circuit, crystal oscillator, analog signal multi-channel selection chip, analog signal amplification circuit, high-precision A / D chip, CPU, wireless module, antenna, 8bit DIP switch, etc. The functions and typical selection models of each part are as follows:

[0049] Power supply module: the field equipment is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com