Bidirectional rotary joint with balance mechanism

A technology of rotary joints and balance mechanisms, which is applied in the fields of manipulators, medical science, and endoscopes, and can solve problems such as difficult to use, large space occupation, and increased size and weight of mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

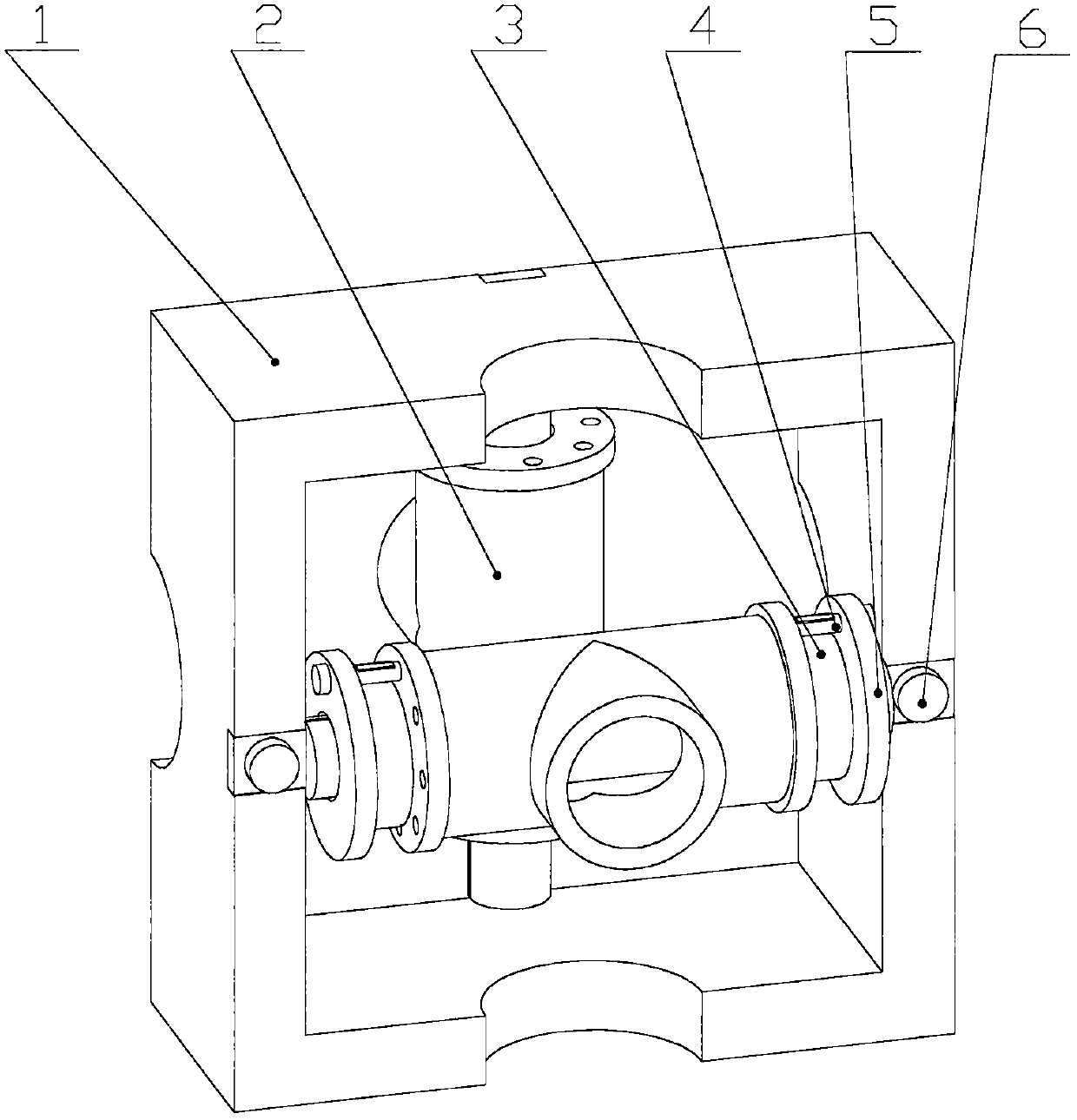

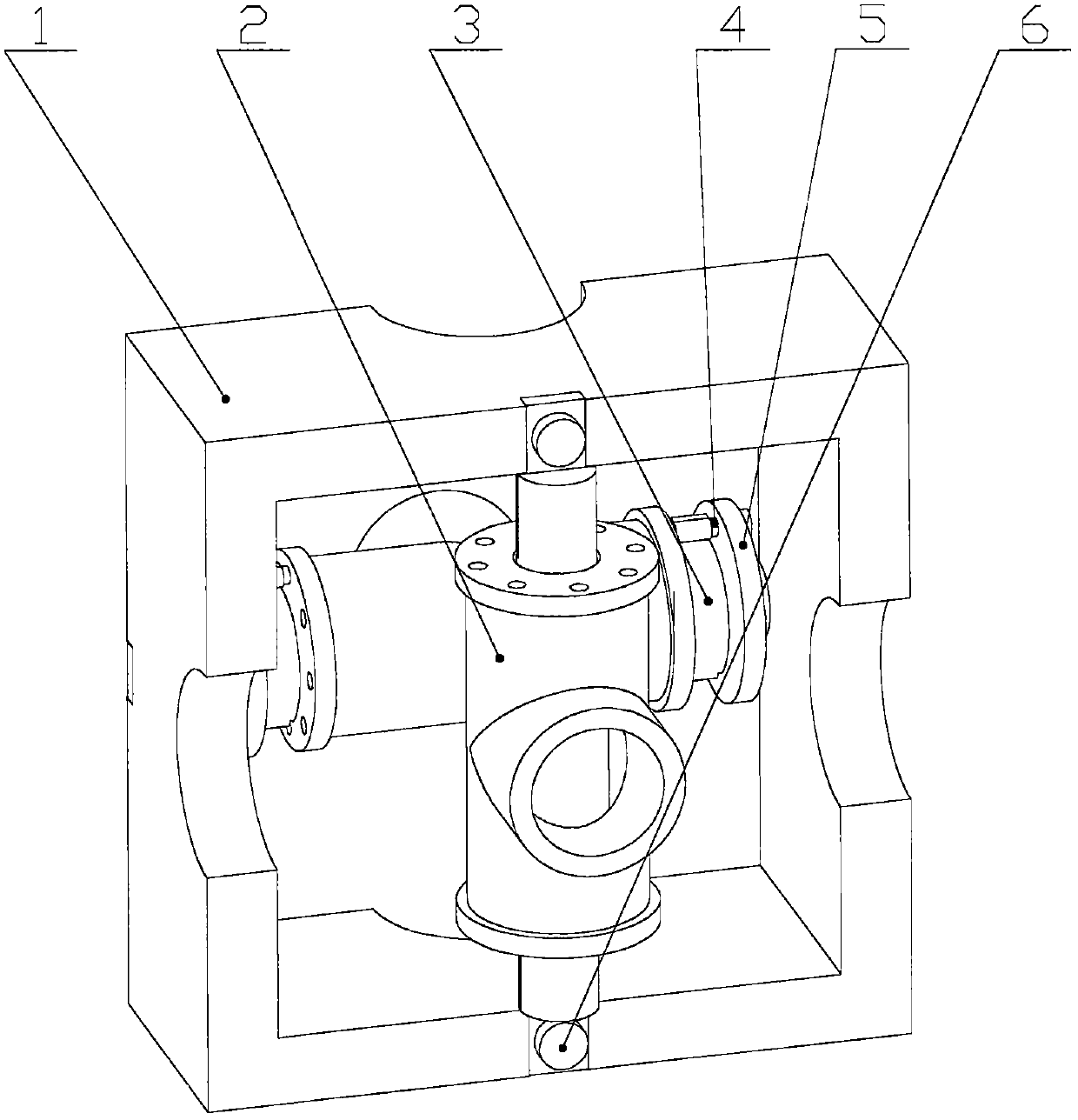

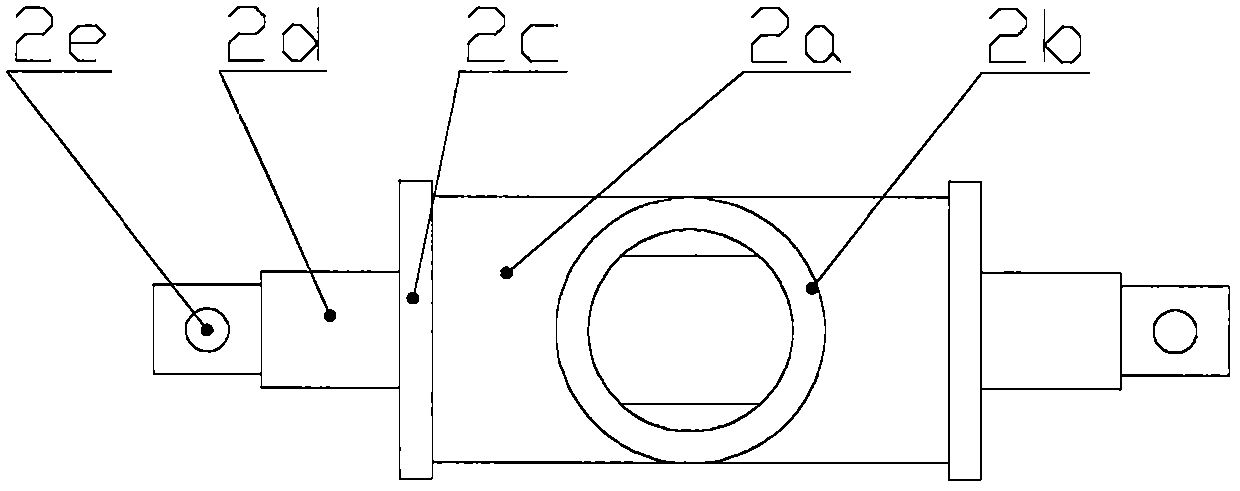

[0018] As shown in the accompanying drawings, the bidirectional rotary joint with a balance mechanism is mainly composed of a bracket, a rotating pair, a spring, etc., and its structure is to have a bracket 1 and two rotating pairs 2; the relative rotation part of the rotating pair 2 is The outer cylinder 2a and the mandrel 2d, there is a connecting rod shaft head 2b outside the outer cylinder 2a; the two ends of the mandrel 2d of the two rotating pairs 2 are respectively fixed on the bracket 1, and the two rotating pairs 2 are in the center When in position, the axes of the connecting rod shaft heads 2b on the two outer cylinders 2a coincide; the main shaft 2d of one or two revolving pairs 2 is covered with the mainspring 3 and the adjusting disc 5 . The details of the structure are: there are screw holes 2e at both ends of the mandrel 2d, and the screws 6 pass through the holes 2e to fix the mandrel 2d on the bracket 1; the two ends of the mandrel 2d also have positioning gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com