Acoustical board under subway seat

A technology for sound-absorbing panels and seats, which is applied in railway car bodies, railway car body parts, transportation and packaging, etc. Good effect, improve sound absorption effect, improve the effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

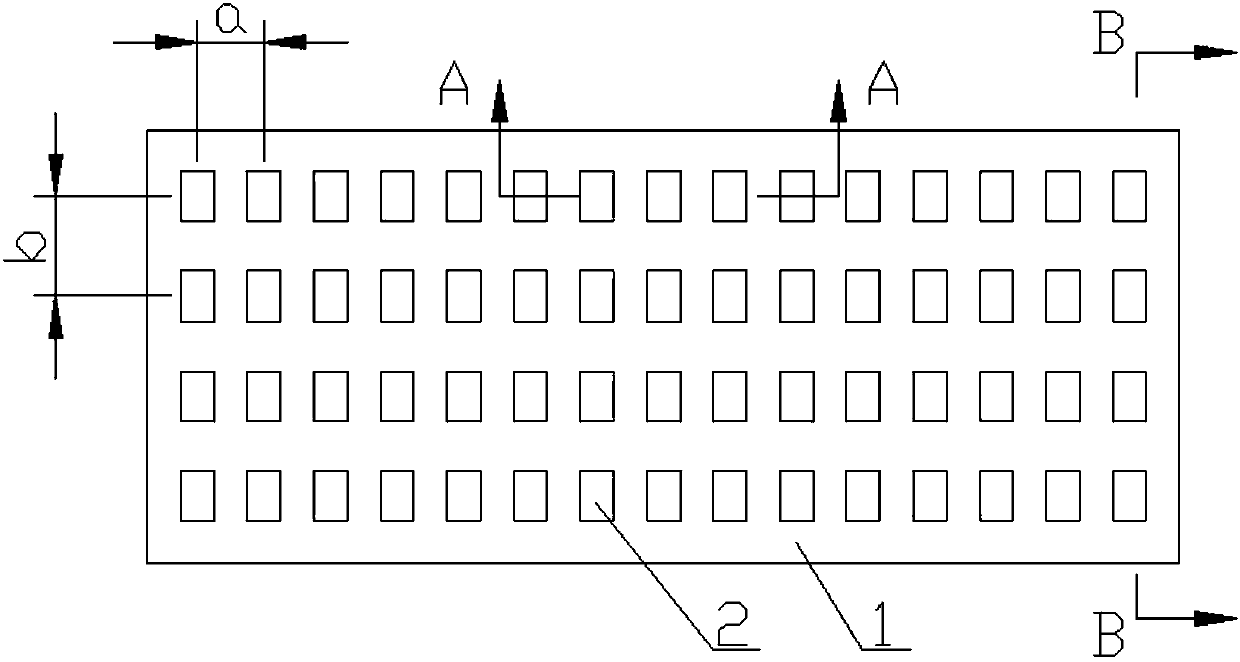

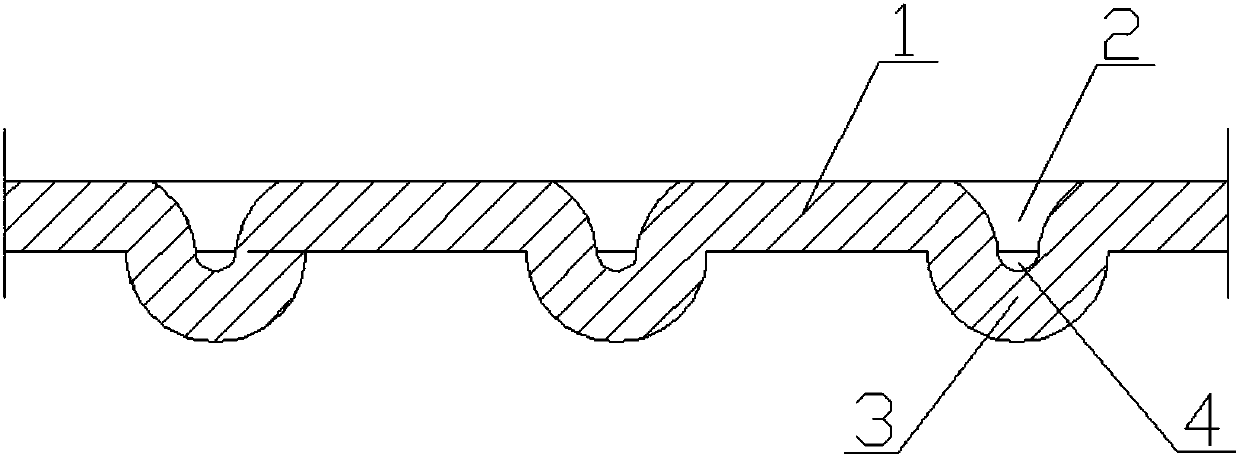

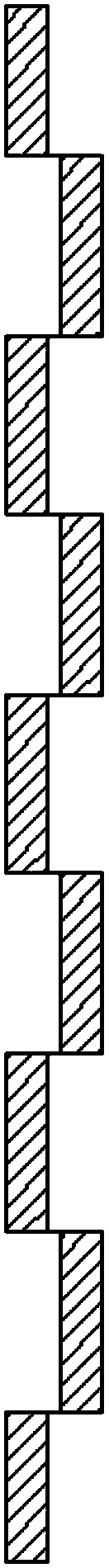

[0039] see Figure 4 , the shape of the depression 2 is a quadrilateral, that is, a rectangle. The quadrilateral includes two long sides and two short sides. At the two long sides of the rectangle, the front of the plate 1 to the front of the depression 2 is an arc transition, and the two short sides of the rectangle The blocking part 3 from the front of the plate 1 to the bottom surface of the depression 2 forms a facade, two micro-perforations 4 are formed on the lower side of the facade, and two micro-perforations 4 are formed corresponding to one depression 2, and the cross-sectional shape of the micro-perforation 4 is convex. Point to the semicircle on the back of the board. The plate 1 has a thickness of 0.7 mm, a length of the long side of 3 mm, and a length of 2 mm of the short side, the width of the micro-perforation 4 is 0.04 mm, and the height of the micro-perforation 4 is 0.02 mm. The perforation rate is 0.52%, the horizontal spacing a is 4mm, and the longitudinal...

Embodiment 2

[0041] see Figure 5 , the shape of the depression 2 is hexagonal, and the hexagon includes three long sides and three short sides. At the three long sides of the hexagon, the front of the plate 1 to the front of the depression 2 is an arc transition, and the three short sides of the hexagon The blocking part 3 from the front of the plate 1 to the bottom surface of the depression 2 forms a facade, three micro-perforations 4 are formed on the lower side of the facade, and three micro-perforations 4 are formed corresponding to one depression 2, and the cross-sectional shape of the micro-perforation 4 is a convex surface Point to the semicircle on the back of the board. The plate thickness is 0.7mm, the length of the long side is 6mm, the length of the short side is 2mm, the width of the micro-perforation 4 is 0.04mm, and the height of the micro-perforation 4 is 0.02mm. The perforation rate is 0.35%, the horizontal spacing a is 6mm, and the longitudinal spacing b is 9mm.

Embodiment 3

[0043] see Image 6 , the shape of the depression 2 is an octagon, and the octagon includes four long sides and four short sides. At the four long sides of the octagon, the front of the board plate 1 to the front of the depression 2 is an arc transition, and the four short sides of the octagon are The front of the plate 1 at the edge reaches the barrier part 3 of the bottom surface of the depression 2 to form a facade, four micro-perforations 4 are formed on the lower side of the facade, four micro-perforations 4 are formed corresponding to one depression 2, and the cross-sectional shape of the micro-perforation 4 is a convex surface Point to the semicircle on the back of the board. The plate 1 has a thickness of 0.7 mm, a length of the long side of 4 mm, a length of the short side of 2 mm, the width of the micro-perforation 4 is 0.04 mm, and the height of the micro-perforation 4 is 0.02 mm. The perforation rate is 0.25%, the horizontal spacing a is 12mm, and the longitudinal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com