Medicinal intermediate storage equipment facilitating heat dissipating

A storage device and intermediate technology, which is applied in the field of pharmaceutical intermediate storage devices to achieve the effects of facilitating heat dissipation, good heat dissipation, and promoting air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

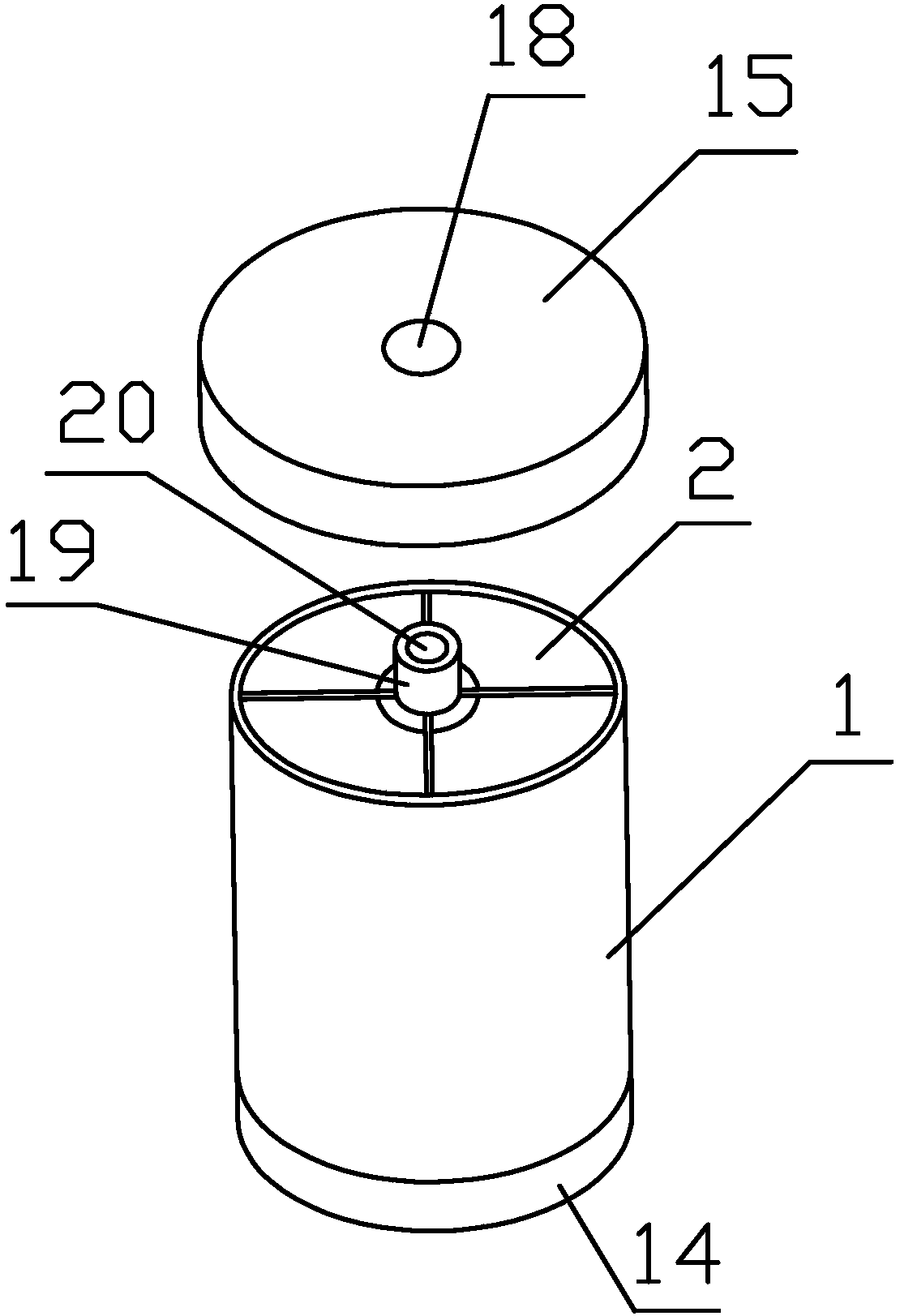

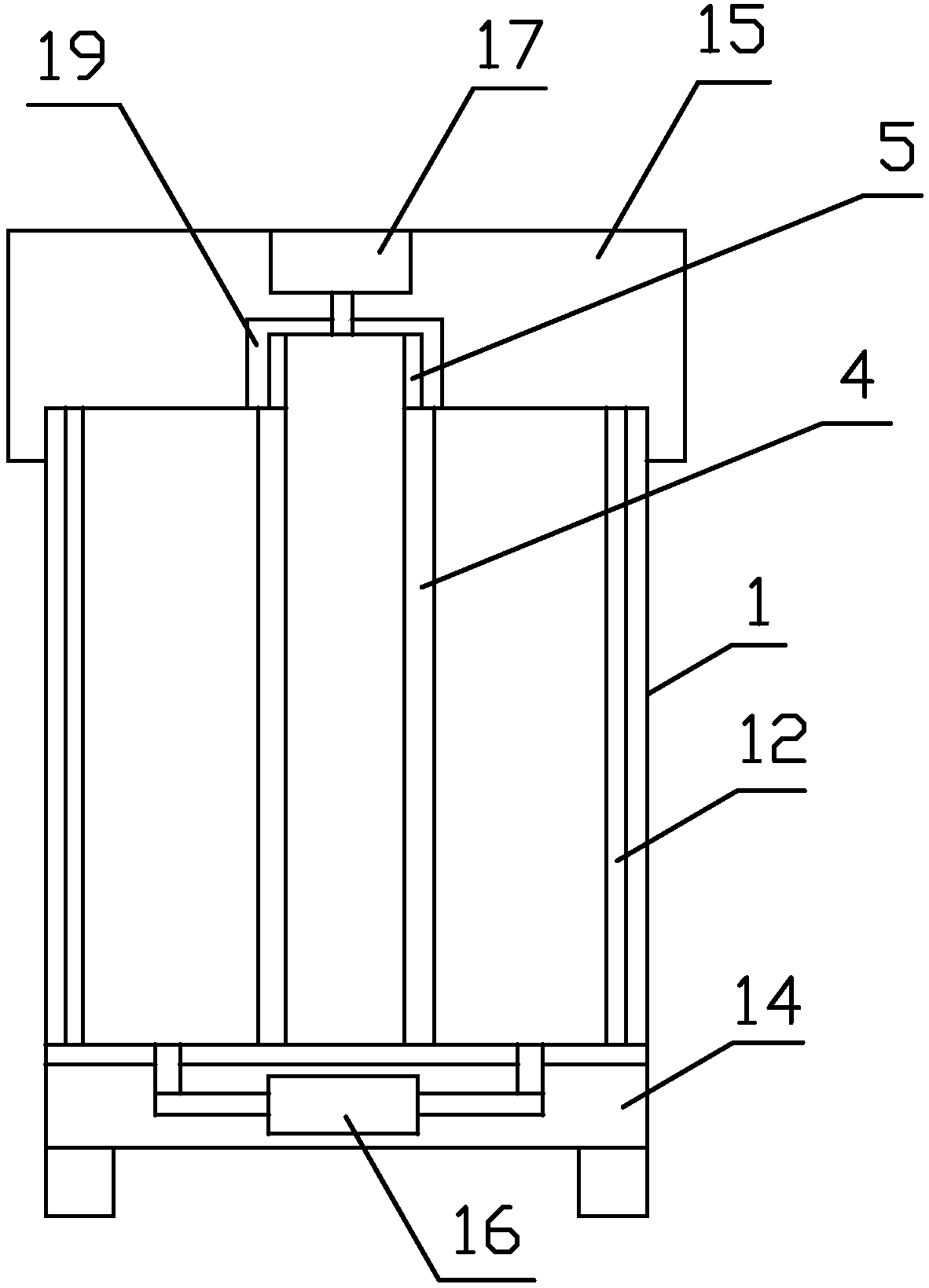

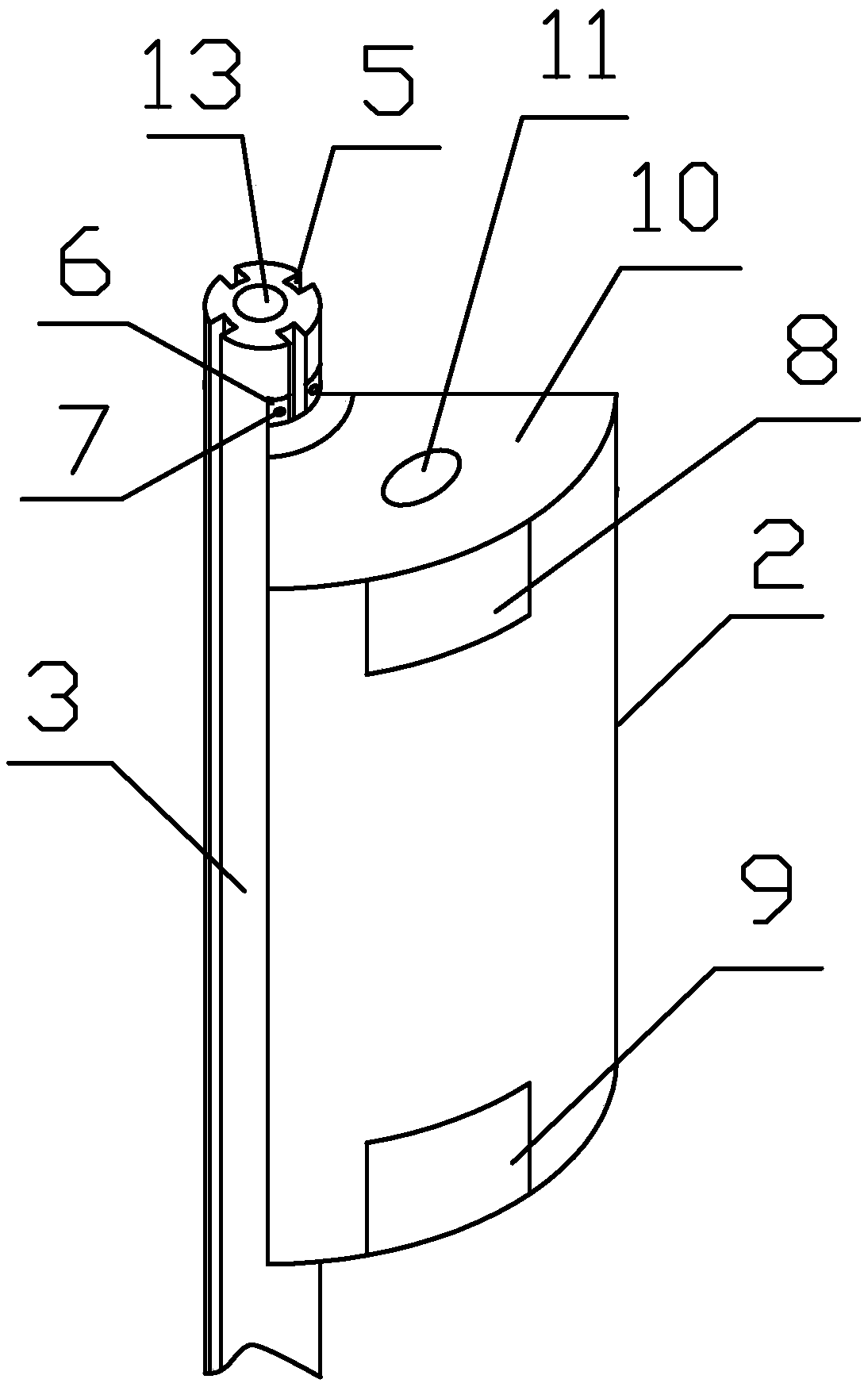

[0029] Such as Figure 1~3 As shown, the pharmaceutical intermediate storage device that is beneficial to heat dissipation of the present invention includes a vertical cylinder 1, and is characterized in that the cylinder 1 is provided with a plurality of boxes 2 with fan-shaped radial sections, and the boxes 2 The axial direction is parallel to the axial direction of the cylinder body 1; the inner bottom surface of the cylinder body 1 is provided with a fixed column 3, and the axis line of the fixed column 3 coincides with the axis line of the cylinder body 1; the box body 2 A slide block 4 is protruded on the side wall where the radial center is located, a chute 5 adapted to the slide block 4 is provided on the side wall of the fixed column 3, and a convex end surface of the axial top end of the box body 2 An arc-shaped fixed plate 6 is provided, and the fixed plate 6 is fixed on the fixed column 3 by bolts 7; the fixed column 3 is provided with a ventilation duct 13 along t...

Embodiment 2

[0031] Further improvement on the basis of Embodiment 1, the upper end of the side wall of the box body 2 radially away from the center of the circle is provided with a feeding port 8 , and the lower end is provided with a feeding port 9 . The axial top end of the box body 2 is integrally provided with a cover plate 10, and the cover plate 10 is made of transparent material. The cover plate 10 is also provided with a lifting ring 11 . Several strip-shaped rubber pads 12 protrude from the inner wall of the cylinder body 1 , and the axial direction of the rubber pads is parallel to the axis of the cylinder body 1 against moisture.

Embodiment 3

[0033] Further improvement on the basis of Example 2, the axial top end of the fixed column 3 is also provided with a connecting cap 19, the protective cap 19 is screwed to the axial top end of the fixed column 3, and the top end of the connecting cap 19 is provided with a through hole 20 , the through hole 20 is used to communicate with the input end of the ventilation pipe 13 and the second suction fan 17 . The base 14 is integrated and fixedly connected with the bottom end of the cylinder body 1; the top cover 15 is connected with the top end of the cylinder body 1 through an O-shaped rubber ring for detachable sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com