Hydraulic control system with dual-pressure compensation of anchor and mooring equipment

A hydraulic control system and pressure compensation technology, which is applied in the improvement field of hydraulic control system, can solve the problems of easy heating of the system, reduction of the opening degree of the main control valve spool, increase of throttling at the main control valve port, etc., and achieve operation Convenience, eliminate throttling and heat generation, and work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

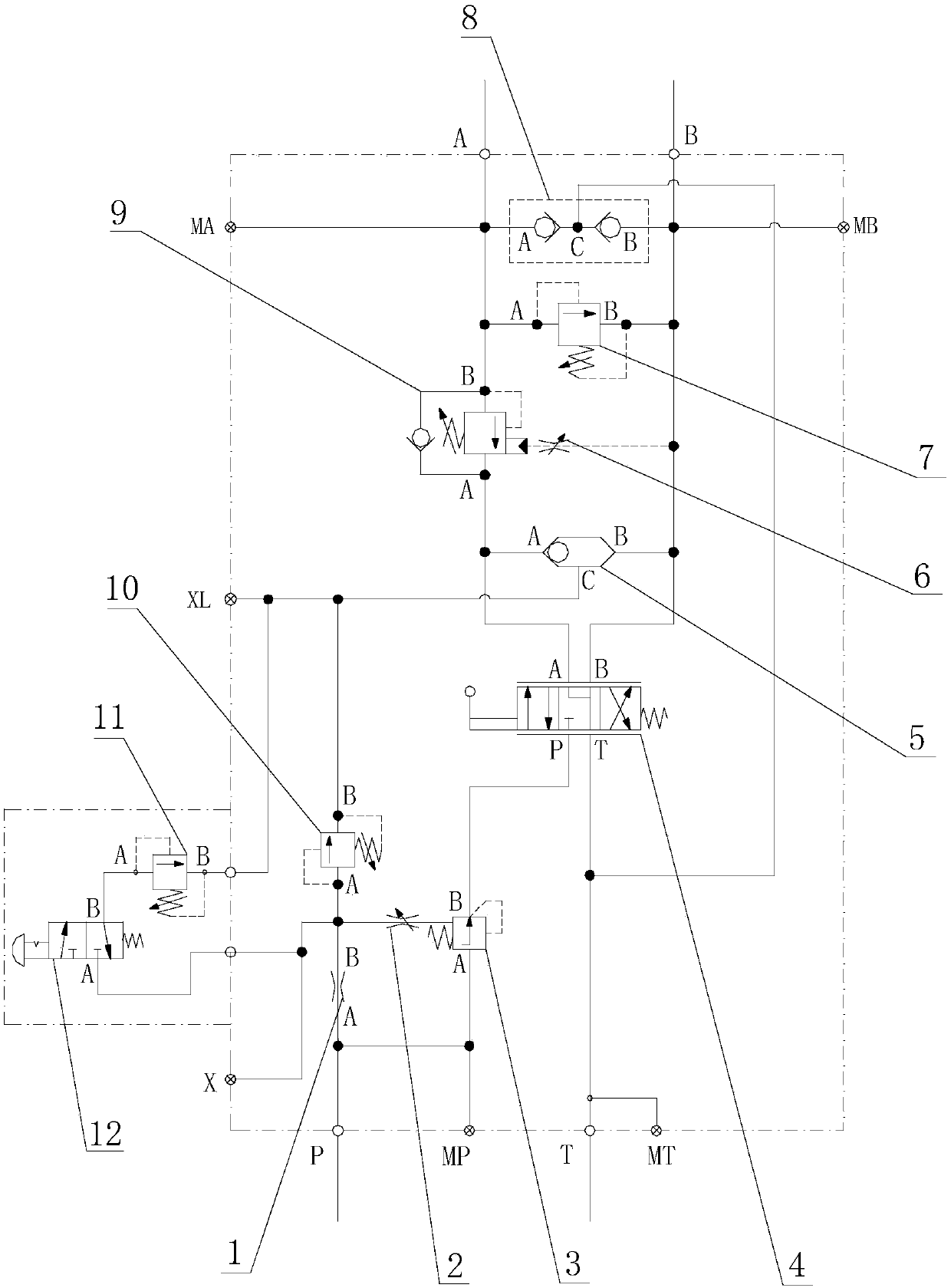

[0019] This embodiment provides a hydraulic control system for anchor windlass with double pressure compensation, its structure is as follows figure 1 As shown, it includes damping plug 1, first adjustable throttle valve 2, pressure compensation valve 3, three-position four-way manual proportional directional valve 4, shuttle valve 5, second adjustable throttle valve 6, relief valve 7 , Double one-way valve group 8, balance valve 9, first pressure compensation pilot valve 10, second pressure compensation pilot valve 11 and two-position three-way manual proportional reversing valve 12. The hydraulic control system also includes a system oil inlet P connected to the system oil source. The system oil inlet P is divided into three routes, the first route is connected to the pressure measuring port MP, and the second route is connected to the first working oil port of the damping plug 1. A is connected, and the third line is connected to the oil inlet A of the pressure compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com