Epoxy resin self-leveling anti-static floor

An epoxy resin and self-leveling technology, applied in the field of flooring, can solve the problems of not being able to produce according to requirements, waste of technical materials, and unqualified technology, and achieve good mechanical properties, long-lasting anti-static effect, improved impact resistance and weight resistance The effect of pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

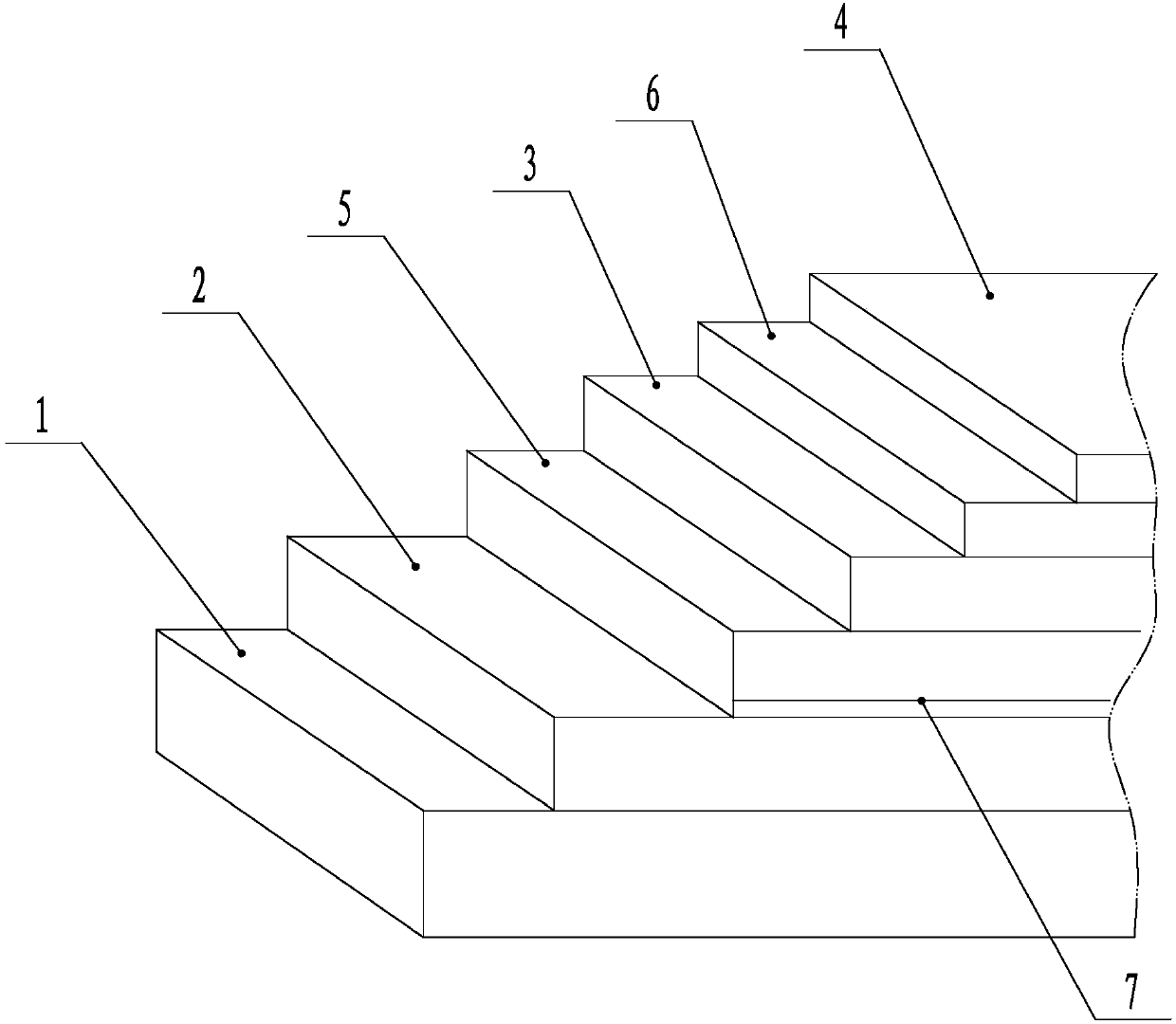

[0014] refer to figure 1 , a preferred embodiment of the present invention, an epoxy resin self-leveling type antistatic floor, includes a concrete base 1, and a primer layer 2, a putty layer 3 and a top coat 4 are sequentially arranged above the concrete base 1, and the The base coat 2 is painted with epoxy anti-static primer, and the top coat 4 is sprayed with epoxy self-leveling anti-static top coat by spraying machine, so that the surface of the floor is smooth and beautiful, and can reach a mirror surface Effect, between the base coat 2 and the putty layer 3, there is also an intermediate coating mortar layer 5, between the putty layer 3 and the top coat 4, a sealing layer 6 is arranged, and the thickness of the sealing layer 6 is preferably 0.2-0.4mm. The intermediate coating mortar layer 5 is provided, which greatly improves t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com