Charging device

A technology for supercharging devices, compressors, applied in the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc. Circumferential velocity and mass flow, etc., to achieve the effect of improved efficiency and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

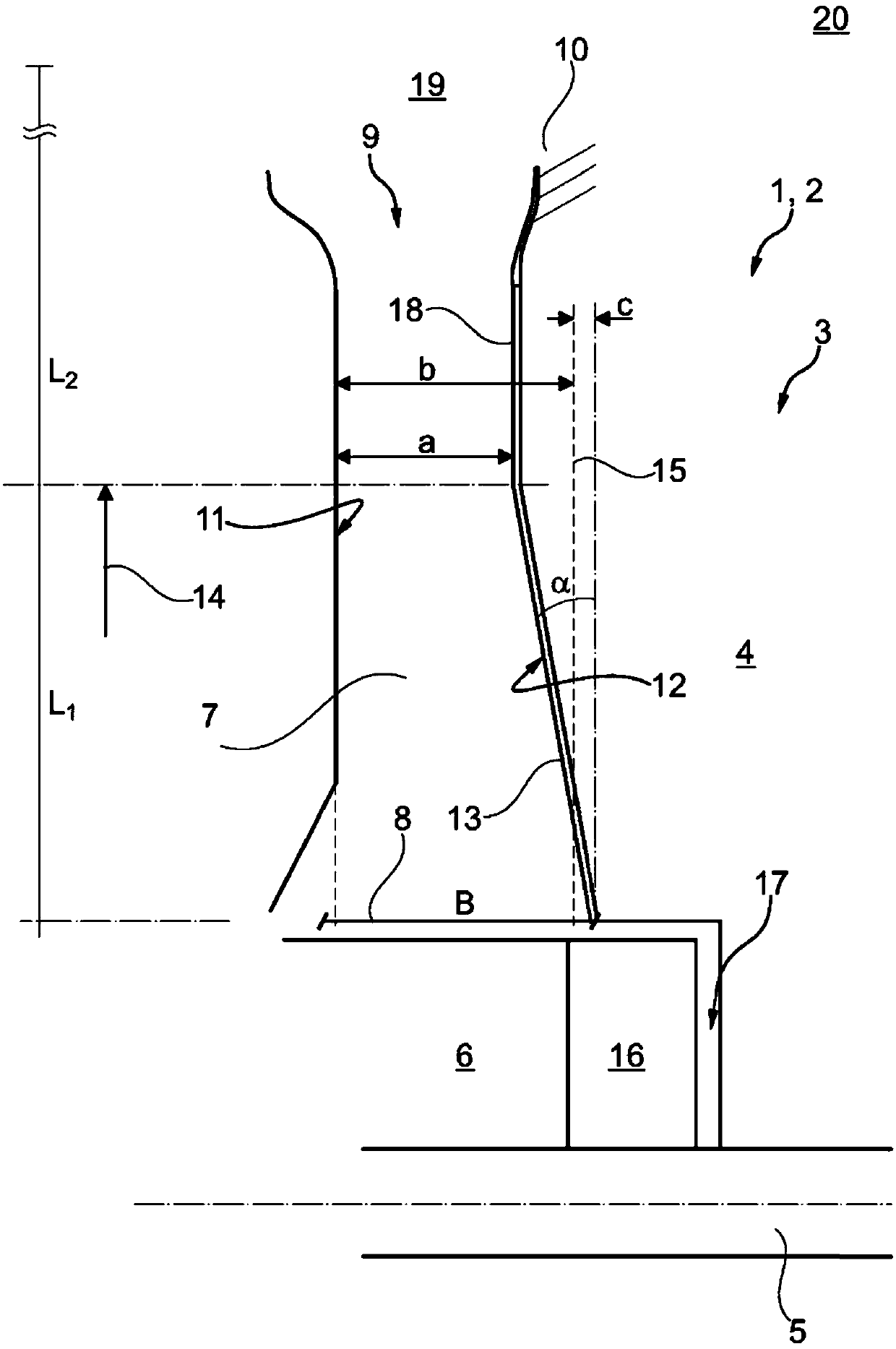

[0015] according to figure 1 , in particular a charging device 1 according to the invention which can be designed as an exhaust-gas turbocharger 2 in a motor vehicle, comprises a compressor 3 and is rotatably mounted on a bearing housing 4 via a compressor wheel 6 arranged thereon. in axis 5. Likewise, the charging device 1 according to the invention comprises a diffuser 7 extending radially from a diffuser inlet 8 on the compressor wheel 6 towards a diffuser outlet 9 on the helical compressor casing 10 . According to the invention, the diffuser 7 is now delimited on the one hand by the diffuser wall 11 and on the other hand by the bearing housing wall 12 . According to the invention, the bearing housing wall 12 is oriented obliquely towards the radial direction 14 at an angle α between 2 and 30° on the first portion arising from the diffuser inlet 8 and brings about a radial direction of the diffuser section 14 Tapering towards the outside. A compressor known from the prio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com