Electronic load parallel operation system and method

An electronic load and system implementation technology, applied in the direction of measuring electricity, power supply testing, measuring electrical variables, etc., can solve the problems that the slave machine does not have the ability to work alone and the power expansion capability is limited, so as to ensure the current and increase the expansion power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

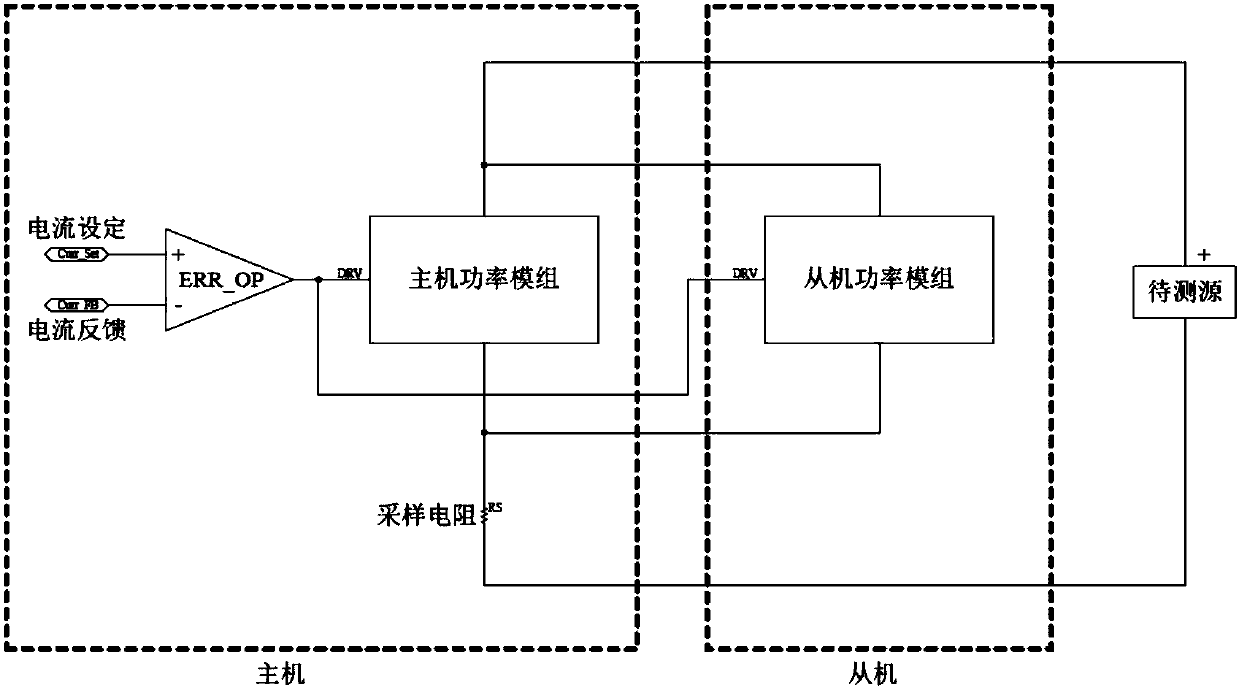

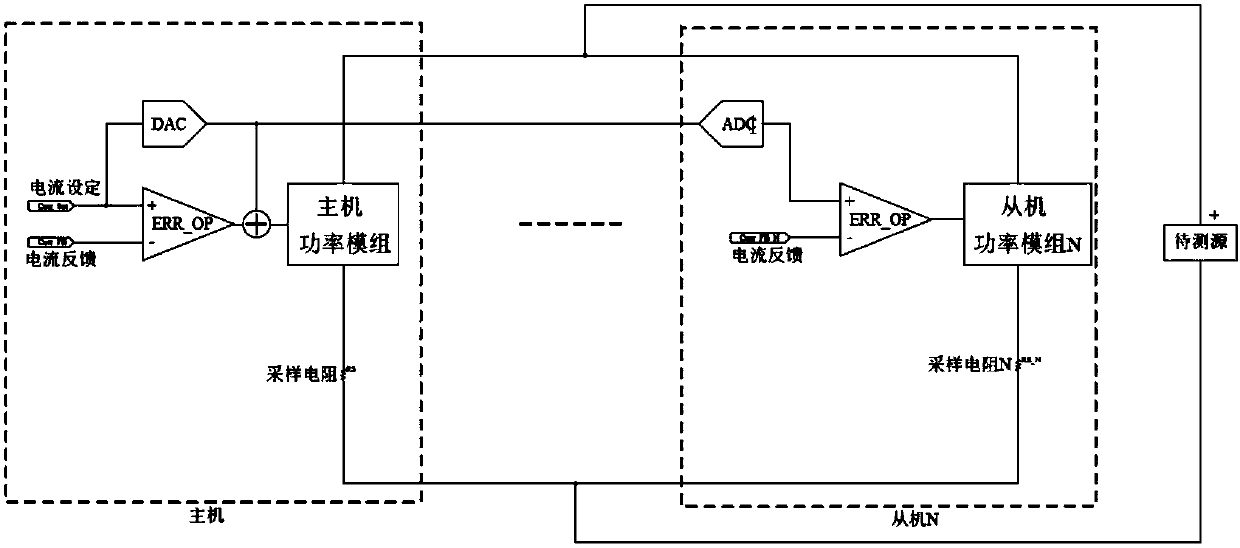

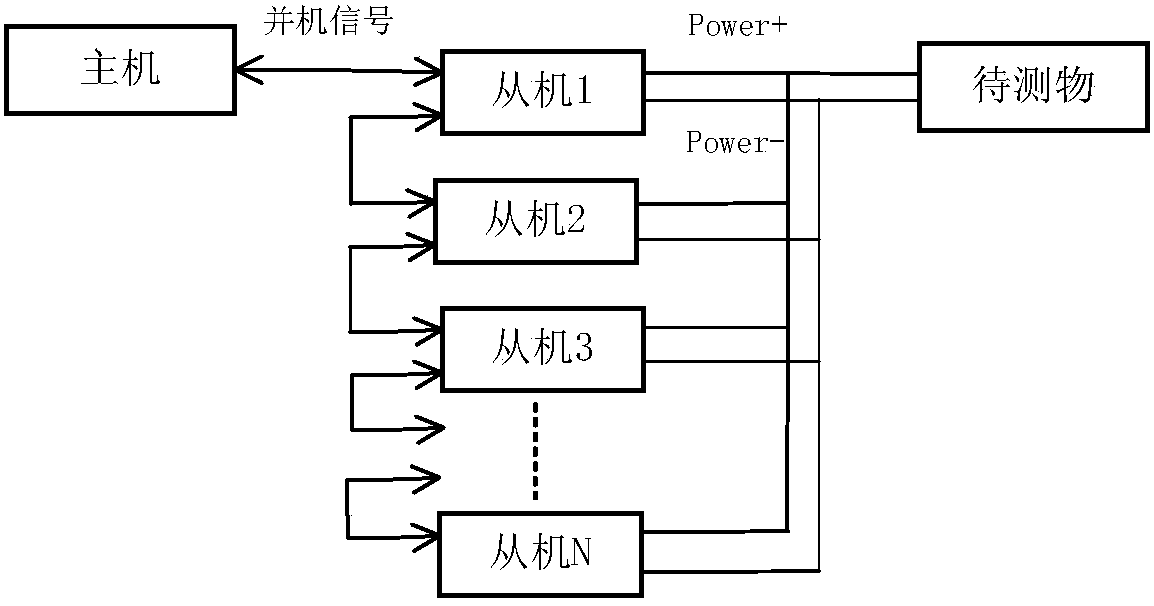

[0071] The electronic load parallel system of the present invention is as image 3 As shown, the electronic load system tests the DUT. The DUT can be a power supply, battery, power supply system, etc. The electronic load system includes a master and multiple slaves. combine Figure 4 to Figure 7 , the host corrects the sink current of the host according to the current setting value to control the main power module to absorb the power on the DUT, and outputs parallel signals including but not limited to drive signals and load synchronization signals in real time according to the current setting value. The slave machine analyzes the current setting value from the parallel machine signal received, and corrects the current drawn by the slave machine according to the current setting value to control the power absorbed by the power module from the DUT. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com