Modeling method for hybrid flow shop energy-saving scheduling by considering shutdown and restart strategy

A modeling method, restarting technology, applied in control/regulation systems, program control, instrumentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

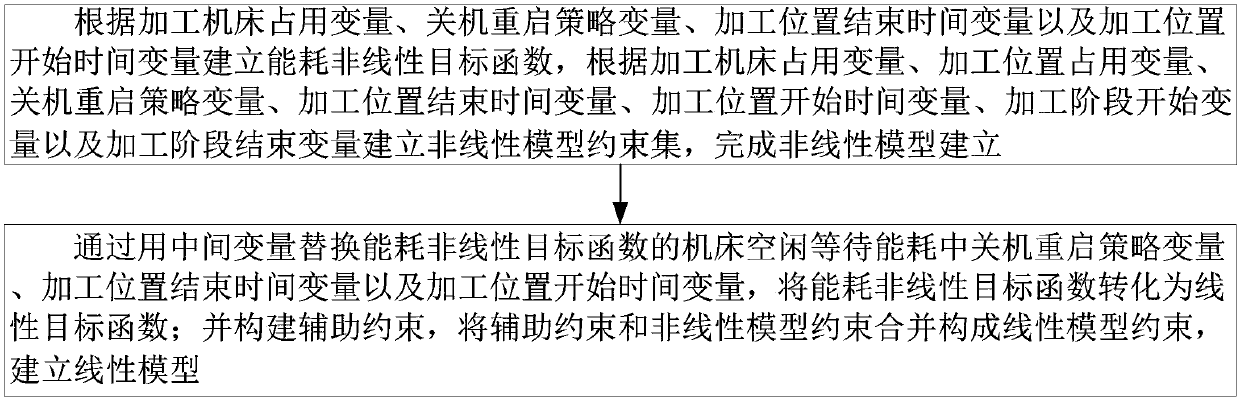

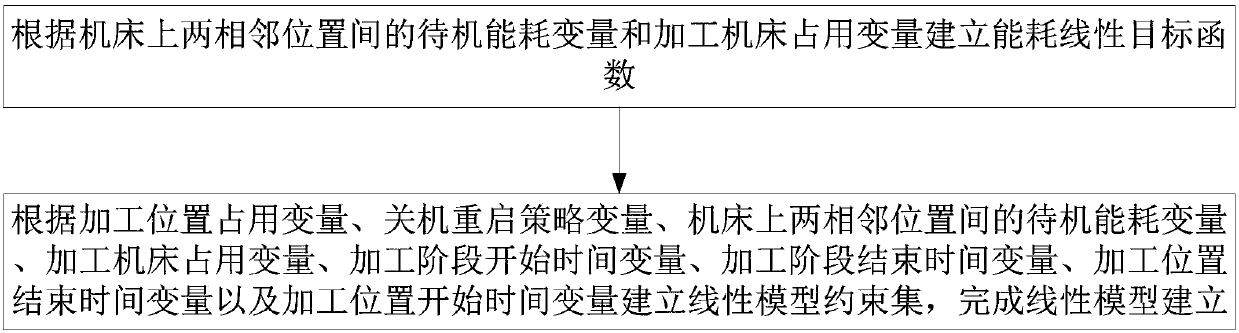

[0197] Model 3: figure 2 The flow chart of the third embodiment of the modeling method for energy-saving scheduling of mixed flow workshops considering shutdown and restart strategies provided by the present invention. The modeling method includes the following steps:

[0198] Introduce decision variables:

[0199] Processing machine tool occupied variable X i,k , indicating whether the i-th workpiece is processed on the k-th machine tool, where

[0200]

[0201] Processing position occupied variable Y i,k,t , indicating whether the i-th workpiece is processed at the t-th position on the k-th machine tool,

[0202]

[0203] Shutdown restart policy variable Z k,t , indicating whether to implement a shutdown and restart strategy between the t-th position and the t+1-th position on the k-th machine tool, where,

[0204]

[0205] Workpiece phase end time variable E i,j , indicating the end time of the j-th processing stage of the i-th workpiece.

[0206] Artifact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com