Roller-type combine harvester of water chestnut

A technology of combine harvester and water chestnut, which is applied in the direction of excavator harvester, harvester, top removal machine, etc., can solve the problems of high labor intensity, high harvesting cost, water chestnut damage, etc., and achieves the effect of improving efficiency and mechanized excavation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

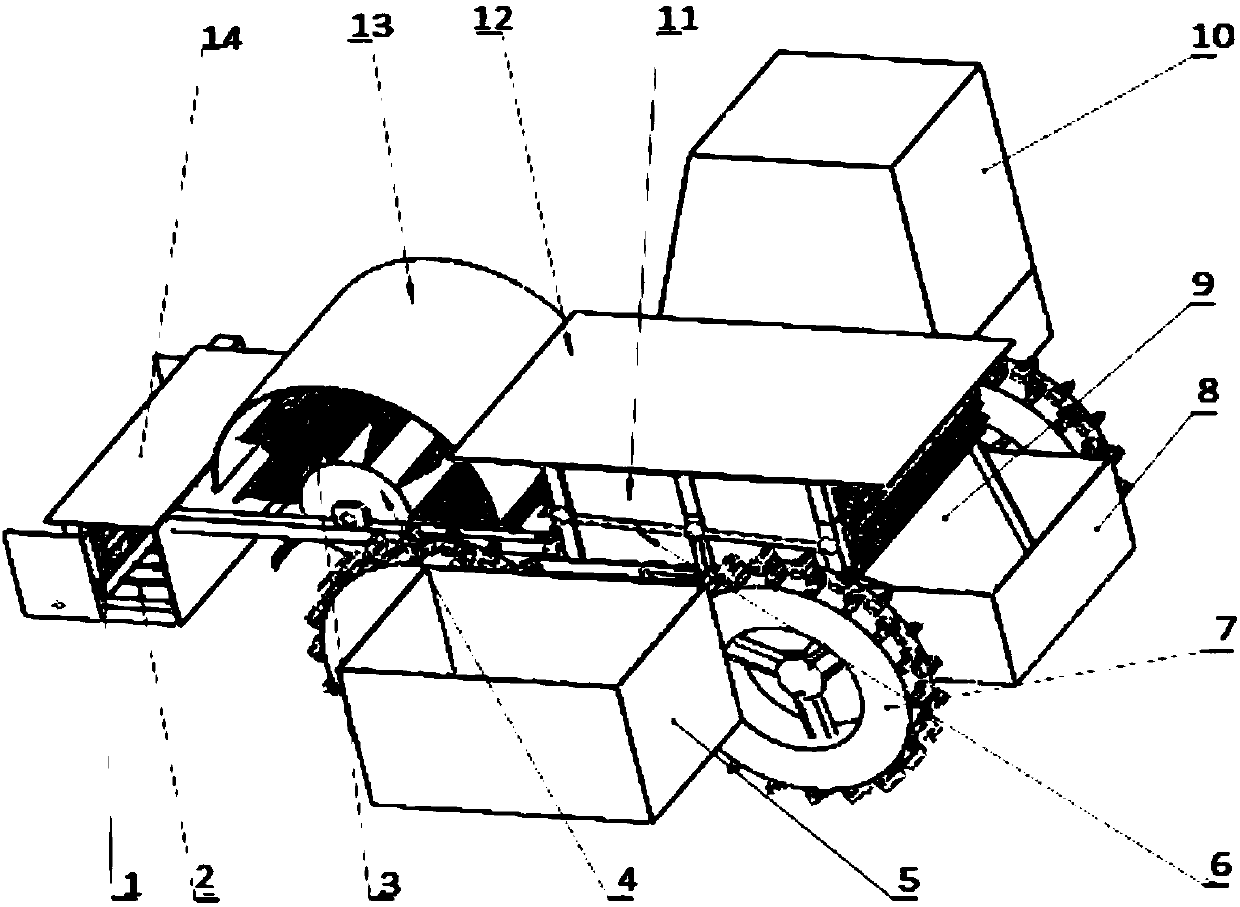

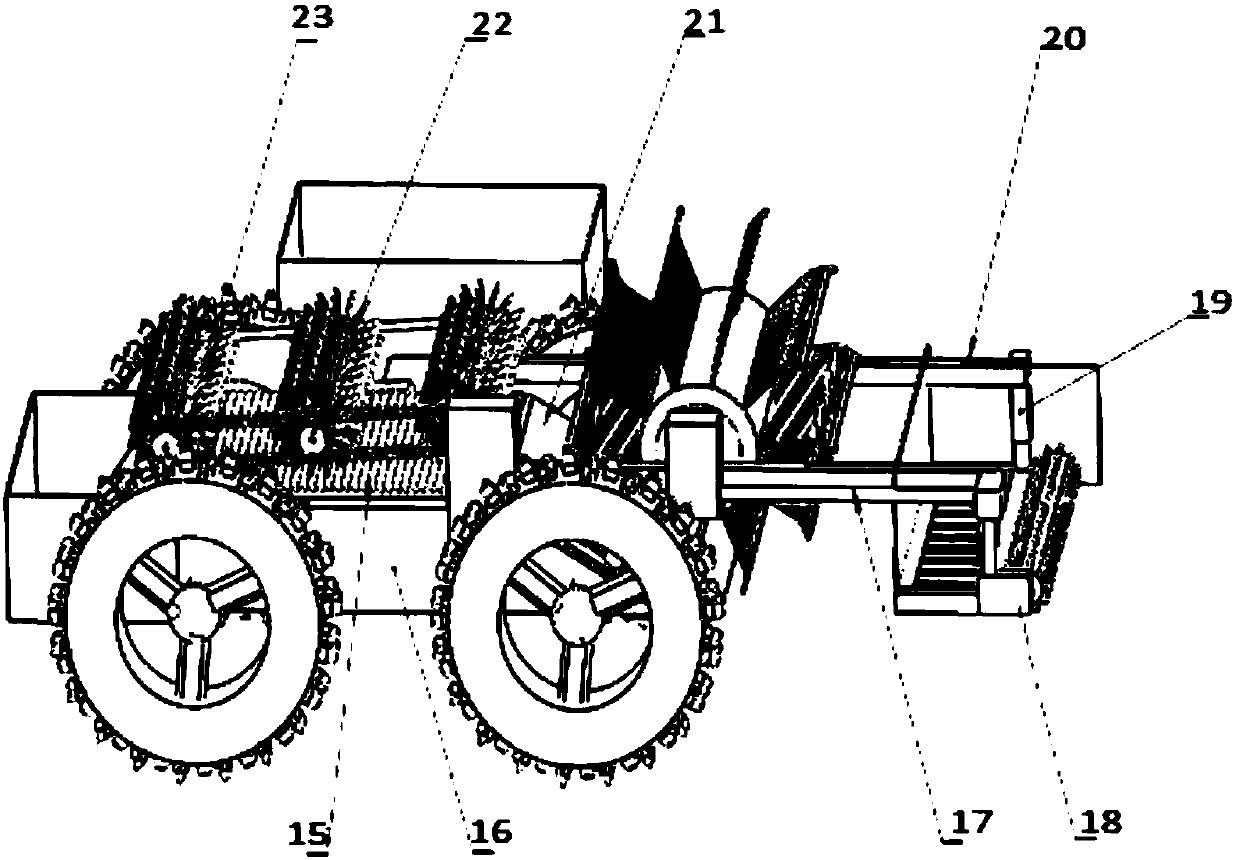

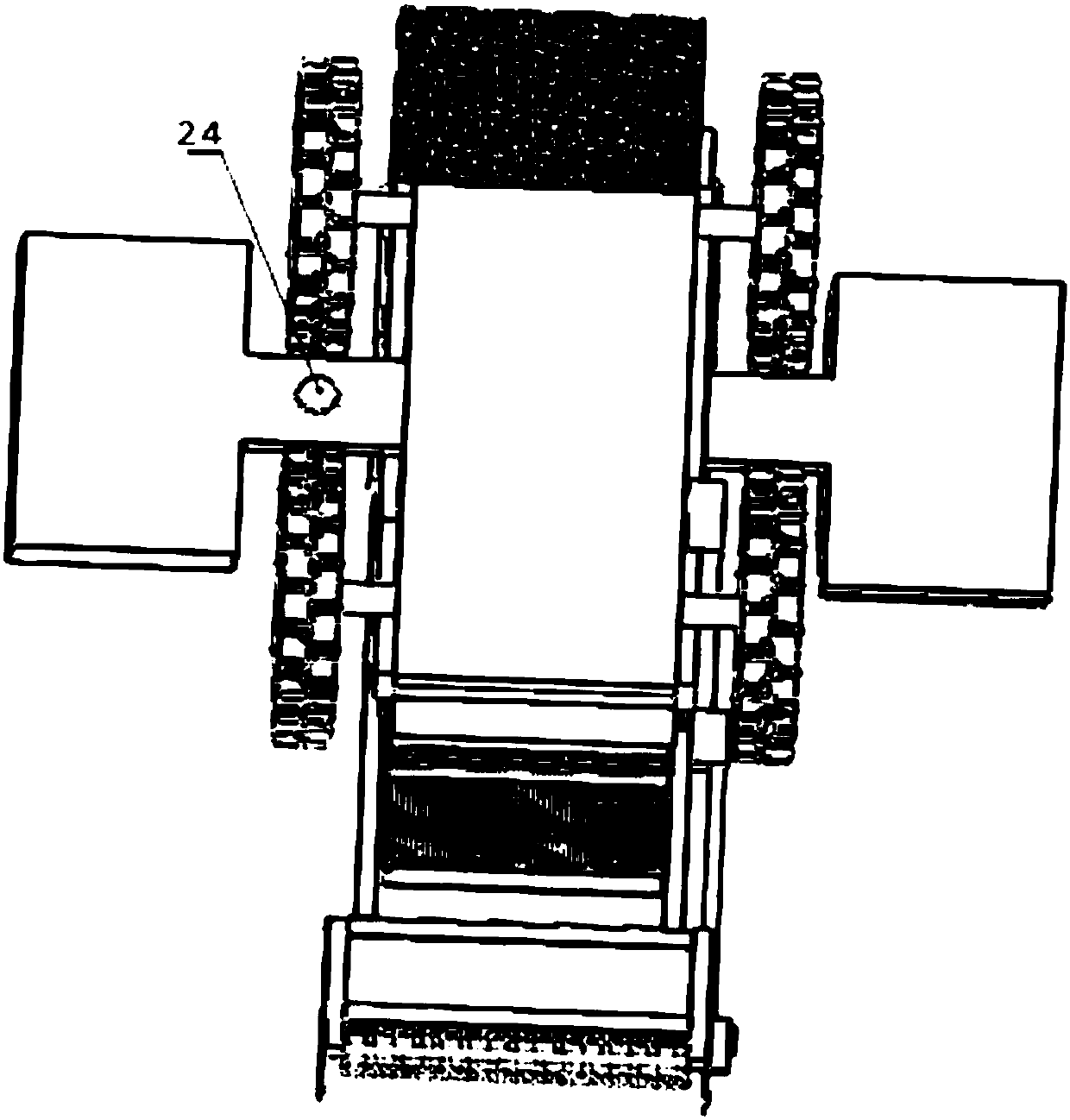

[0032] See attached picture.

[0033] A roller-type water chestnut combine harvester includes a frame 20, and the frame is sequentially equipped with a stem harvesting and cleaning device, a water chestnut excavating device, a water chestnut conveying and cleaning device, and a water chestnut collecting device in sequence from the front end to the tail end; The stalk harvesting and cleaning device includes a bracket that can be adjusted up and down. A nail-toothed cleaning drum 1 is rotated on the bracket, and a stalk cleaning conveyor belt 2 that can be circulated and transversely driven is installed on the rear side of the nail-toothed cleaning drum 1 on the bracket; the water chestnut digging device It includes a cleaning drum installed on the frame, and the annular outer wall of the cleaning drum is equipped with excavation panels 3 for digging water chestnuts at intervals; the water chestnut conveying and cleaning device includes an inclined conveyor belt 21 and Horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com