Power battery module separation equipment for electric vehicle

A power battery and separation equipment technology, which is applied in the field of power battery module separation equipment for electric vehicles, can solve problems such as high risk, easy fire or explosion, environmental pollution, etc., to achieve disassembly without discharge, and prevent fire or Explosion, the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

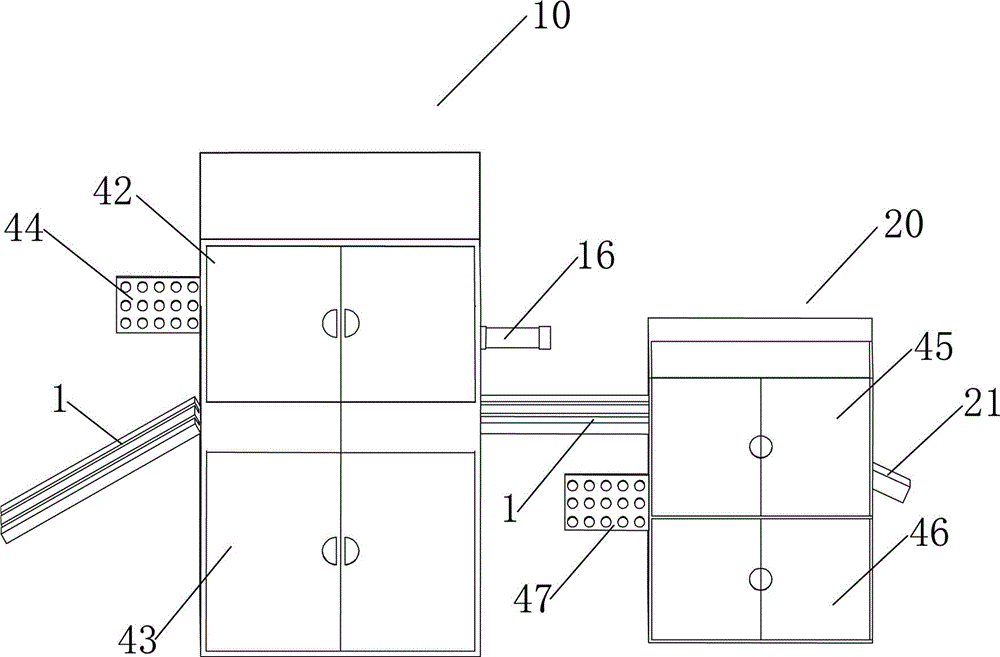

[0022] Such as figure 1 shown. A power battery module separation device for an electric vehicle, comprising an outer frame dismantling area 10 and a monomer dismantling area 20 for separating a battery module 48, and a track 1 passing through the outer frame dismantling area 10 and the monomer dismantling area in sequence In the dismantling area 20, the track 1 is provided with an automatic crawler cart 2 for transporting the battery module 48, and the dismantling area 20 is a sealed space, and a rare gas inlet 3 is provided on it.

[0023] Wherein, the monomer dismantling area 20 is filled with a rare gas through the rare gas inlet 3; wherein, the volume ratio of the rare gas is 95% for argon, 3% for neon, and 2% for helium.

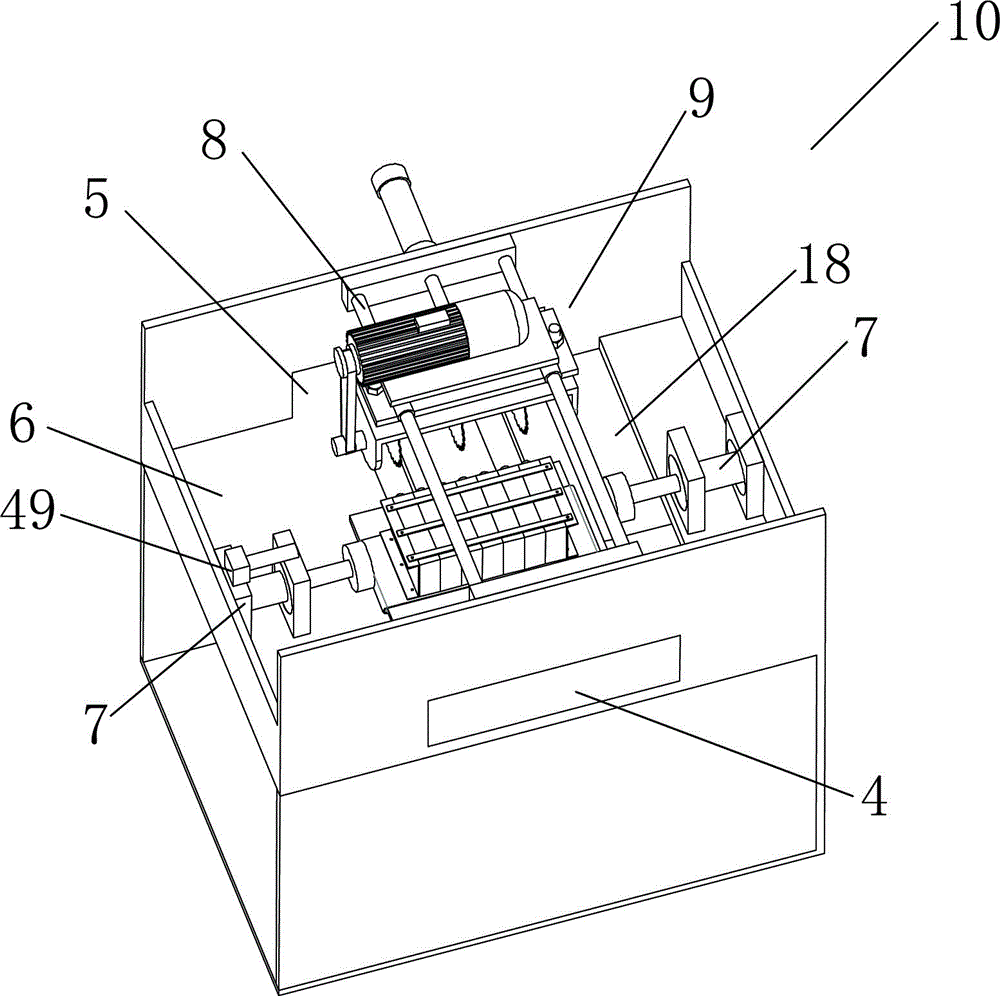

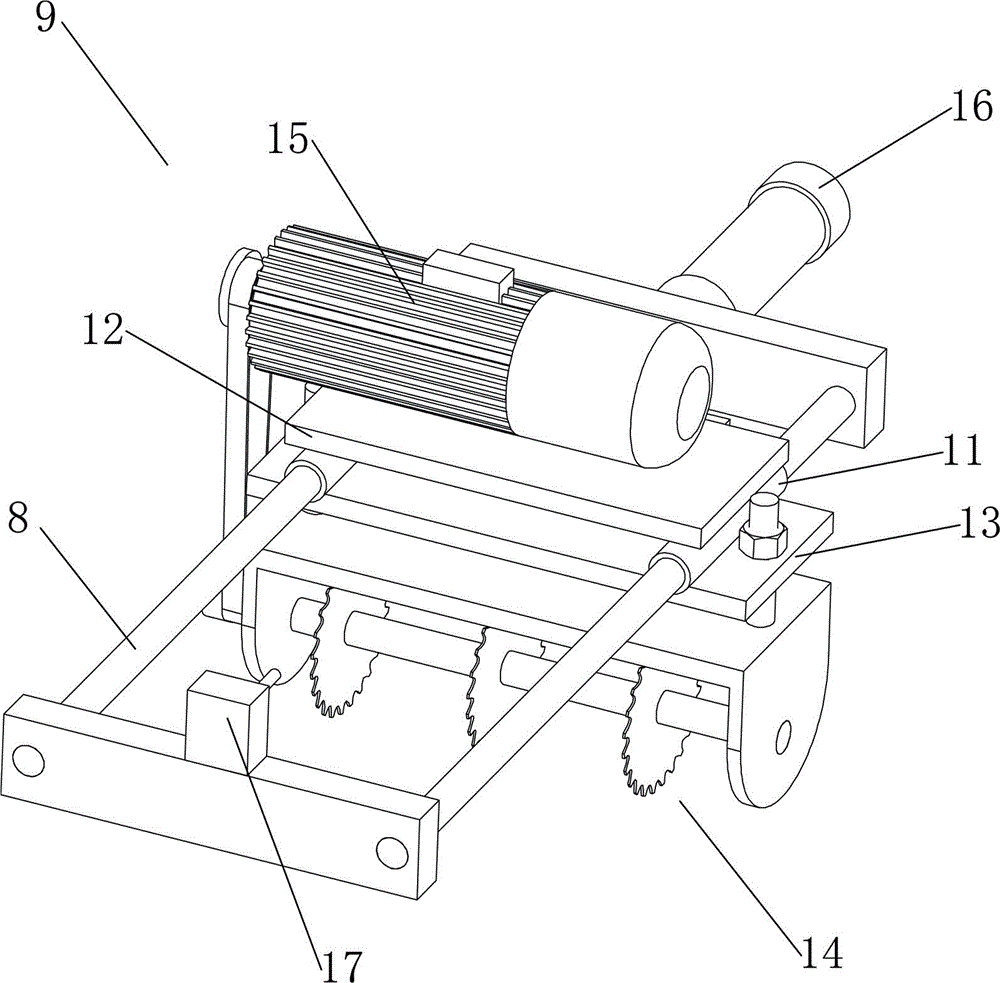

[0024] Such as figure 2 , image 3 shown. The outer frame dismantling area 10 is a box-type structure, and the left and right sides of the outer frame dismantling area 10 are respectively provided with a feed door I4 and a discharge door I5 for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com