Transmission box sealing structure of wire drawing machine

A sealing structure and transmission box technology, which is applied to the sealing of engines, transmission parts, mechanical equipment, etc., can solve problems such as inability to guarantee normal production, affect the operation and production efficiency of the wire drawing machine, and reduce the lubrication performance of the transmission box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

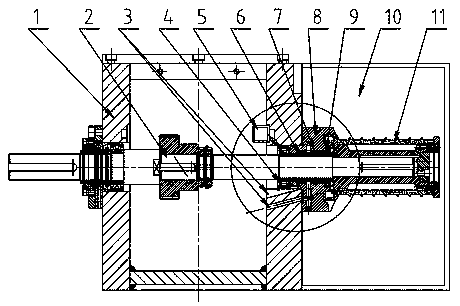

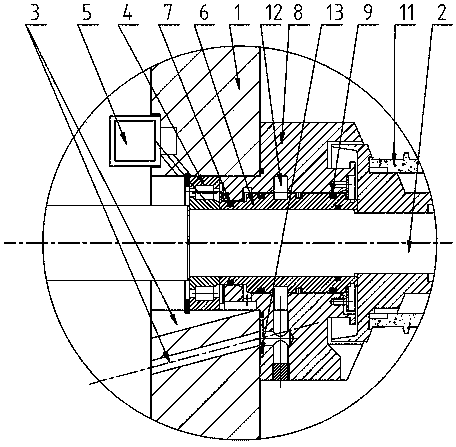

[0016] exist figure 1 In the sealing structure of the transmission box of the wire drawing machine shown, the transmission box 1 is a long box member, and a number of wire drawing axles 2 are rotatably supported on the transmission box 1. Each wire drawing axle 2 is arranged along the length direction of the transmission box 1. The wire drawing drive motor is driven to rotate by a gear pair, the gear pair is located in the transmission box 1, the wire drawing axle 2 passes through the side wall of the transmission box 1 and is rotatably supported on the transmission box 1 by the bearing 4, and the extended end of the wire drawing axle 2 is located in the wire drawing chamber Inside 10 , the wire drawing chamber 10 is a wire drawing working space in a closed casing, and the wire drawing wheel 11 is installed on the extended end of the wire drawing wheel shaft 2 in the wire drawing chamber 10 . see figure 2 , an oil delivery pipe 5 is installed on the inner wall of the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com