A shock-resistant self-cleaning glass

A glass, self-cleaning technology, applied in glass/slag layered products, metal layered products, chemical instruments and methods, etc., can solve problems such as poor seismic performance, enhance decorative performance, improve bulkiness and air permeability, Enhanced anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

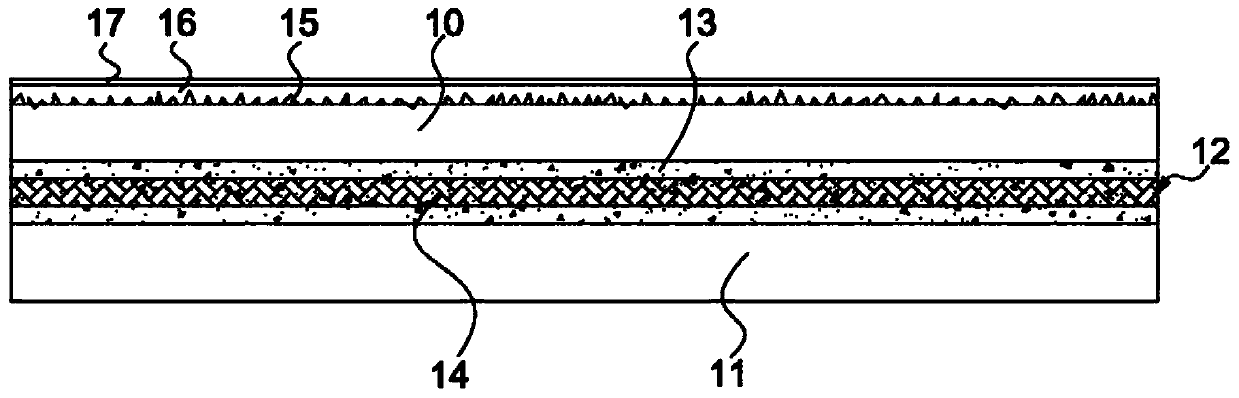

[0020] Implementation 1, see figure 1 Shown: an anti-seismic self-cleaning glass, comprising an upper glass base layer 10 and a lower glass base layer 11, a spacer layer 12 is arranged between the upper glass base layer 10 and the lower glass base layer 11, and a braided layer 14 is arranged in the spacer layer 12 And poured with edge-sealing glue 13, the edge-sealing glue 13 tightly wraps the weaving layer 14 and tightly fits the upper glass-based layer 10 and the lower glass-based layer 11 together; the upper surface of the upper glass-based layer 10 is chemically etched A frosted surface 15 is formed in a manner. A phosphor layer 16 is printed on the frosted surface 15, and the phosphor layer 16 is printed by screen printing, and the grid size of the screen printing tool used gradually becomes smaller. A self-cleaning film layer 17 is printed on the upper surface of the phosphor layer 16 . The braided layer 14 is woven by hollow special-shaped fibers, metal fibers and cer...

Embodiment approach 2

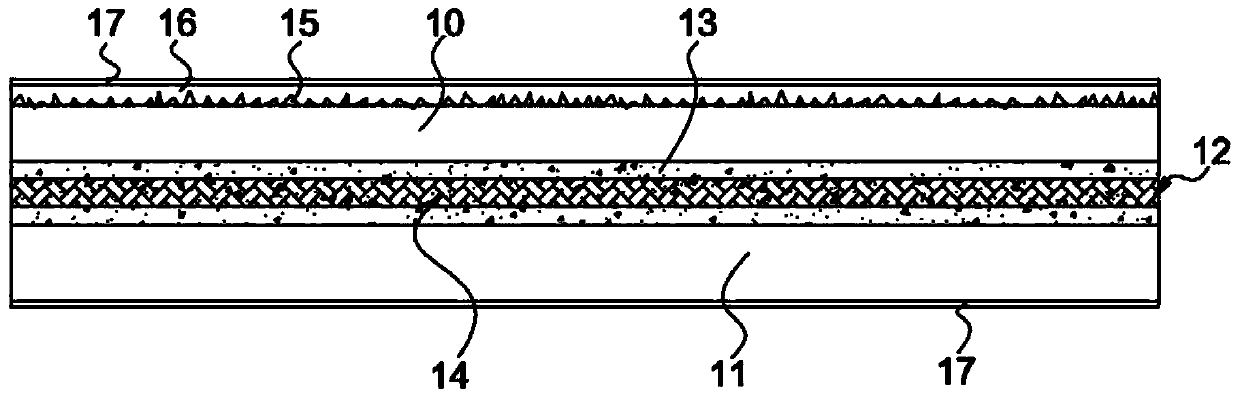

[0023] Implementation 2, see figure 2 Shown: an anti-seismic self-cleaning glass, comprising an upper glass base layer 10 and a lower glass base layer 11, a spacer layer 12 is arranged between the upper glass base layer 10 and the lower glass base layer 11, and a braided layer 14 is arranged in the spacer layer 12 And poured with edge-sealing glue 13, the edge-sealing glue 13 tightly wraps the weaving layer 14 and tightly fits the upper glass-based layer 10 and the lower glass-based layer 11 together; the upper surface of the upper glass-based layer 10 is chemically etched A frosted surface 15 is formed in a manner. A phosphor layer 16 is printed on the frosted surface 15, and the phosphor layer 16 is printed by screen printing, and the grid size of the screen printing tool used gradually becomes smaller. A self-cleaning film layer 17 is printed on the upper surface of the phosphor layer 16 . The braided layer 14 is woven by hollow special-shaped fibers, metal fibers and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com