Milk powder tank with storage function

A milk powder can and function technology, which is applied to the parts, packaging, bottles and other directions of bottles/cans, can solve the problems of unfavorable carrying out, inconvenient operation, and bringing into the can, so as to be beneficial to carrying, storage and operation when going out. Convenience and hygiene, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

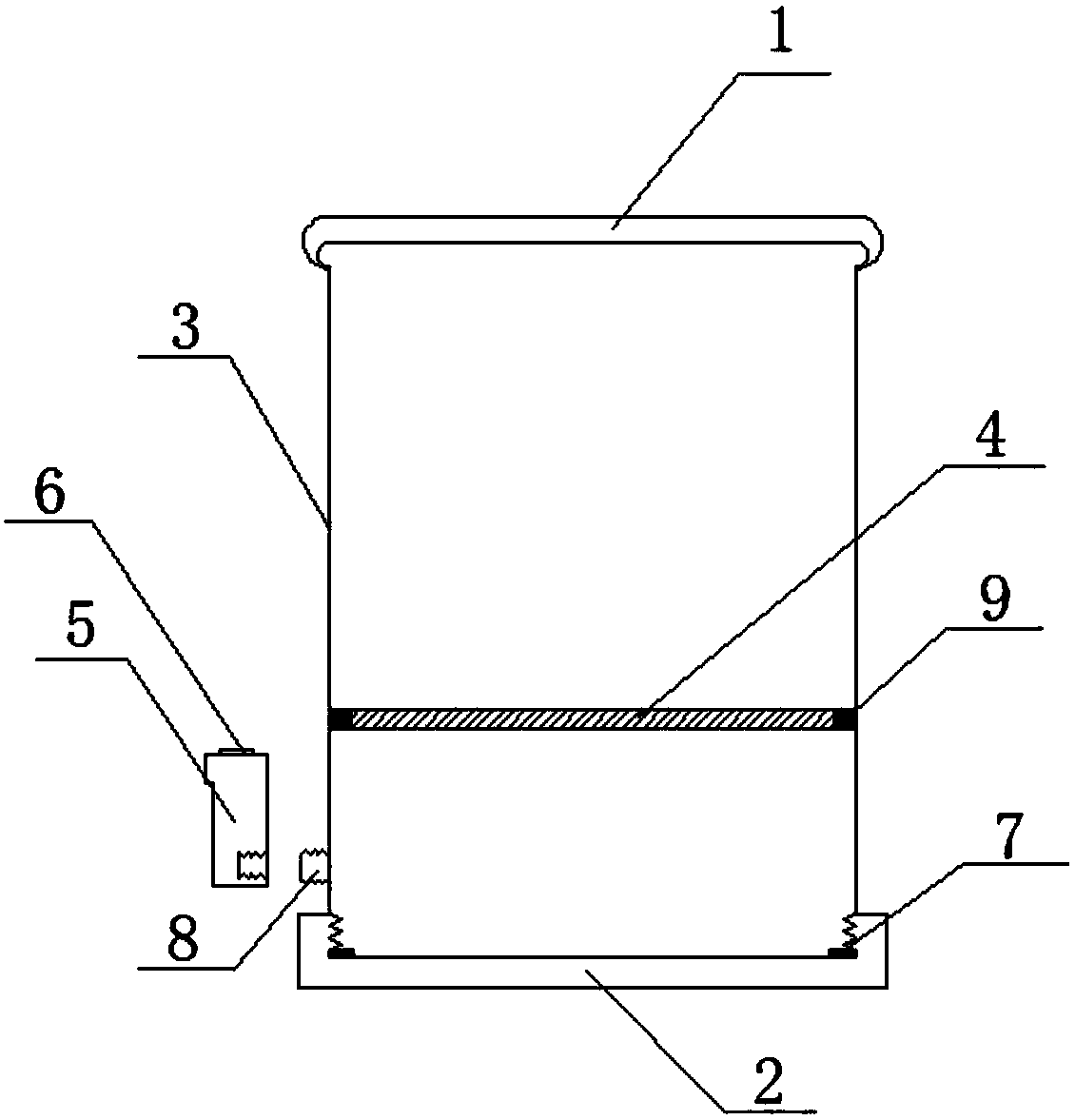

[0026] Such as figure 1 As shown, a milk powder can with a storage function includes: a top cover 1, a bottom cover 2, a can body 3 and a partition 4, and the partition 4 divides the can body 3 into an upper chamber and a lower chamber , a second sealing ring 9 is installed at the joint between the outer wall of the partition 4 and the inner wall of the tank body 3, and the partition 4 can slide up and down in the tank body 3; the tank body is provided with The detachable air pressure device 5 and the opening 8 for the air inlet and outlet of the air pressure device 5 are used to change the pressure of the lower chamber to provide power for the partition 4 to slide on the can body 3 .

[0027] The thickness of the partition 4 is 1 cm; the air pressure device 5 includes a reciprocating pump and a power supply and a switch 6 electrically connected to the reciprocating pump, and the air pressure control of the lower chamber is realized by the reciprocating pump; the bottom A fir...

Embodiment 2

[0032] The present invention provides a milk powder can with storage function. Compared with Example 1, the difference is that the second sealing ring 9 is an elastic food-grade silicone sealing ring body, which not only connects the partition plate 4 with the The tank body 3 has a certain cushioning property, and can also play a good sealing effect. When the partition plate 4 moves upward, it can effectively prevent milk powder from remaining in the lower chamber.

Embodiment 3

[0034] The present invention provides a milk powder can with a storage function. Compared with Example 1, the difference is that the can body 3 is provided with a transparent observation belt in the vertical direction, and the air pressure device 5 is opened to change the lower cavity chamber pressure, so that the partition 4 moves on the can body 3, observe the storage volume of milk powder through the transparent observation belt, and close the air pressure device 5 when it reaches a suitable position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com