Green brick transfer machine for refractory brick salt leaching process

A transfer machine, refractory brick technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as accumulation of position errors of brick cages, accidents, and tilt of brick cages, and achieve a simple and lightweight overall structure. Reliable effect of force state and working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

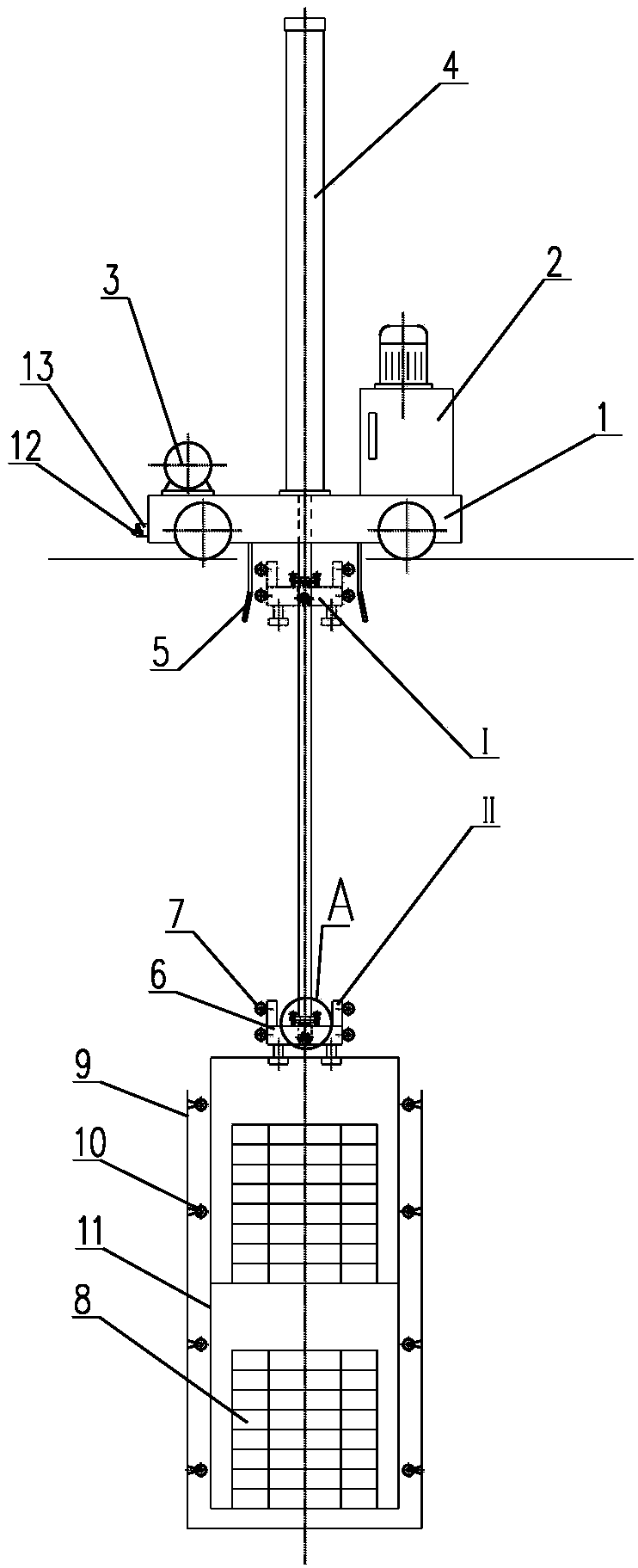

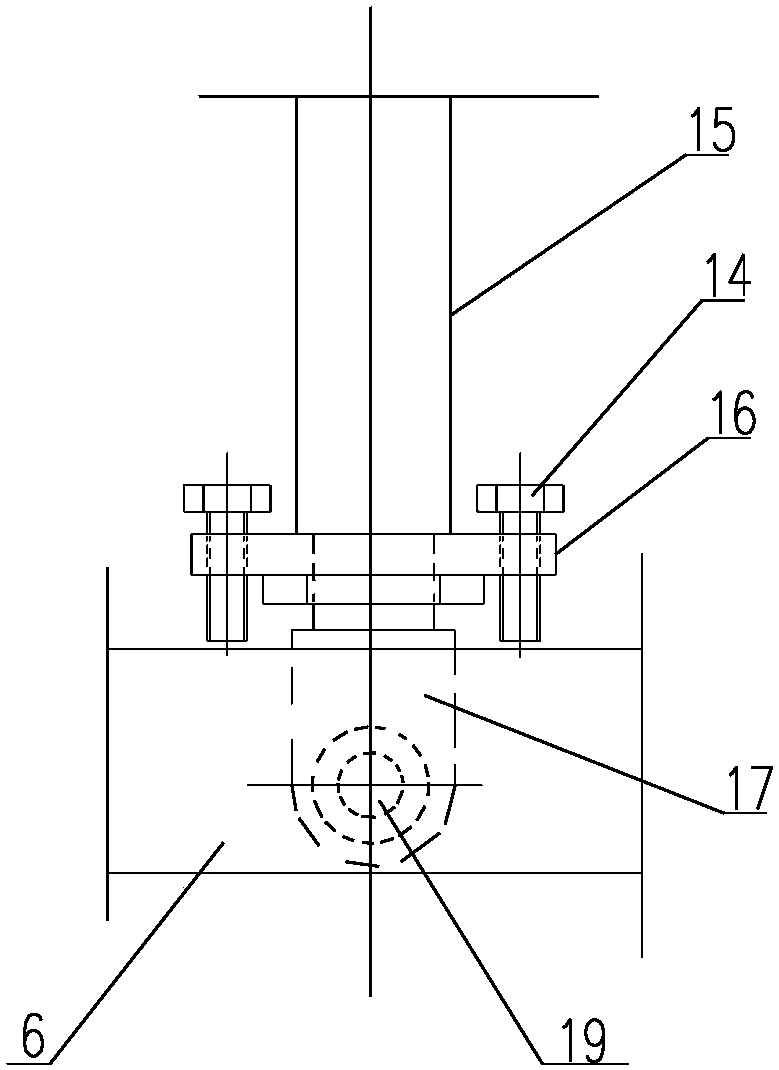

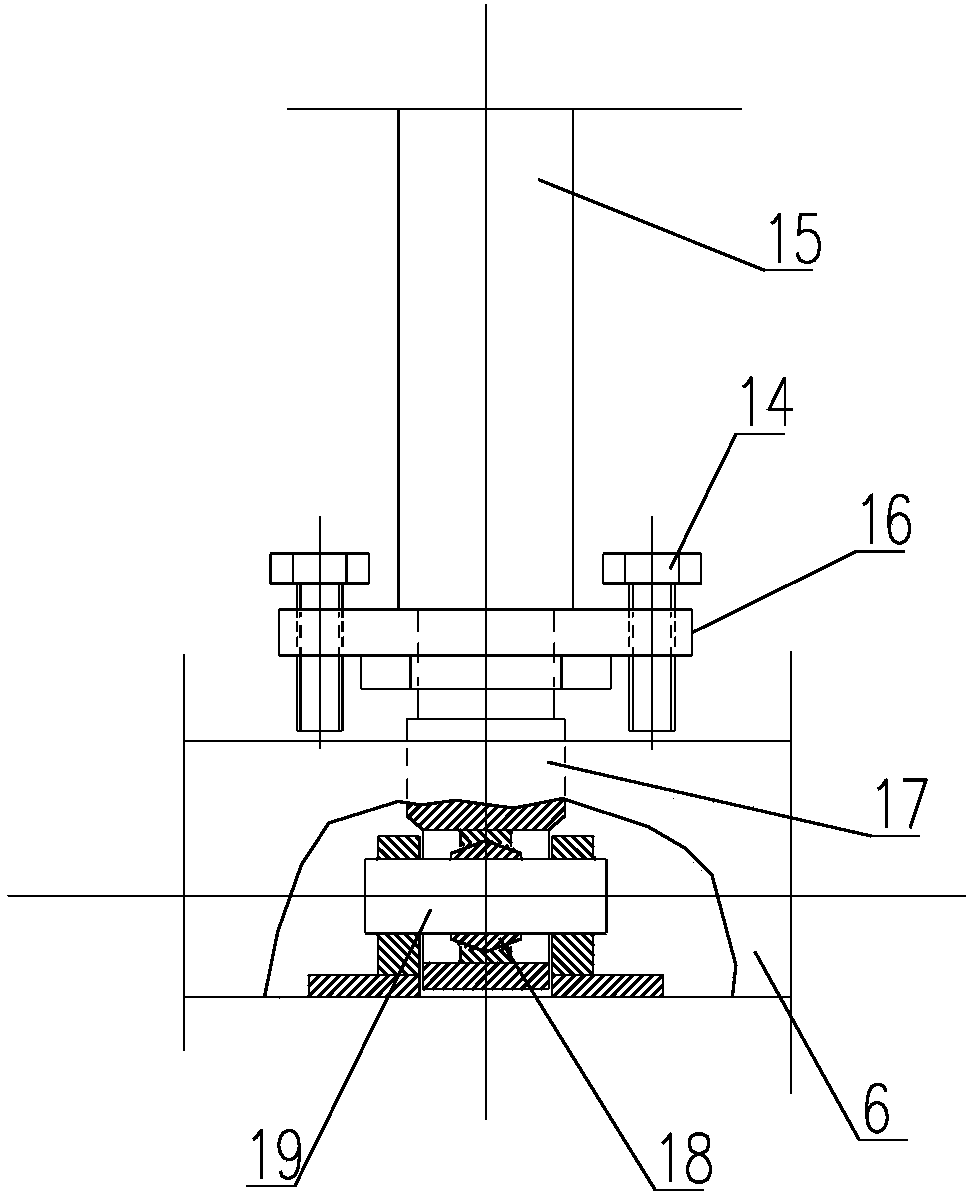

[0019] like figure 1 As shown, a brick adobe transfer machine for refractory brick salt immersion process according to the present invention is arranged on the guide rail above the salt immersion tank 9; it includes a traveling car body 1, a lifting hydraulic cylinder 4, a vehicle-mounted guide rail 5 and a brick cage spreader 6 The traveling car body 1 is provided with traveling wheels, which can walk along the guide rail under the driving of the traveling drive device 3; The protruding end is connected with the brick cage spreader 6 through a hinged limit mechanism, and the brick cage spreader 6 is used for hoisting the brick cage 11; the spreader guide wheels 7 are arranged on both sides of the brick cage spreader 6, and the hydraulic cylinder piston rod 15 protrudes The bottom of the walking car body 1 on the side is provided with a vehicle-mounted guide rail 5 corresponding to the spreader guide wheel 7; before the brick cage 11 enters the salt soaking tank 9, the spreade...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap