Kasugamycin fermentation culture medium and fermentation method

A fermentation medium and a technology for kasugamycin, which are applied in the field of fermentation, can solve the problems of high energy consumption, long fermentation period of kasugamycin, and high cost of kasugamycin fermentation production, and achieve improved utilization, shortened fermentation time, and increased content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

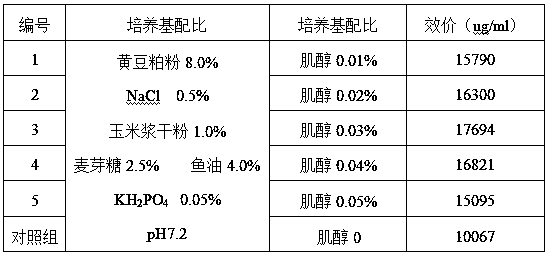

Examples

specific Embodiment approach

[0030] This embodiment discloses a specific embodiment of fermenting kasugamycin, comprising the following steps:

[0031] (1) Preparation of medium, according to the ratio of kasugamycin liquid fermentation medium formula, prepare 1000L medium;

[0032] Soybean meal powder 8.0% NaCl 0.5% Corn steep liquor dry powder 0.8% Maltose 2.5%

[0033] Fish Oil 3.5% KH 2 PO 4 0.03% Inositol 0.03% pH7.0.

[0034] (2) Sterilize the medium at a high temperature of 121-125°C for 30 minutes.

[0035] (3) Lower the temperature of the culture medium to 30°C to inoculate the kasugamycin seed solution with an inoculum volume of 15vol%, and ferment and cultivate.

[0036] (4) Ferment for 170 hours at a fermentation temperature of 28-30°C, ventilation rate of 1:1, stirring speed of 180rpm, and tank pressure of 0.02MPa, and collect and purify the fermentation supernatant to obtain Kasugamycin.

[0037] (5) Take 10mL of fermentation broth in a test tube, adjust the pH to about 2.0-3.0 with 2m...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is only that the proportioning of the fermentation formula is adjusted.

[0040] (1) Preparation of medium, according to the ratio of kasugamycin liquid fermentation medium formula, prepare 1000L medium;

[0041] Soybean meal powder 5.0% NaCl 0.3% Corn steep liquor dry powder 0.5% Maltose 2.0%

[0042] Fish Oil 3.5% KH 2 PO 4 0.03% Inositol 0.01% pH6.8.

[0043] (2) Sterilize the medium at a high temperature of 121-125°C for 30 minutes.

[0044] (3) Lower the temperature of the culture medium to 30°C to inoculate the kasugamycin seed solution with an inoculum volume of 15vol%, and ferment and cultivate.

[0045] (4) Ferment for 170 hours at a fermentation temperature of 28-30°C, ventilation rate of 1:1, stirring speed of 180rpm, and tank pressure of 0.02MPa, and collect and purify the fermentation supernatant to obtain Kasugamycin.

[0046](5) Take 10mL of fermentation broth in a test tube, adjust the pH to a...

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is only that the proportioning of the fermentation formula is adjusted.

[0049] (1) Preparation of medium, according to the ratio of kasugamycin liquid fermentation medium formula, prepare 1000L medium;

[0050] Soybean meal powder 8.0% NaCl 0.5% Corn steep liquor dry powder 1.0% Maltose 2.5%

[0051] Fish Oil 4.0% KH 2 PO 4 0.05% Inositol 0.05% pH7.2.

[0052] (2) Sterilize the medium at a high temperature of 121-125°C for 30 minutes.

[0053] (3) Lower the temperature of the culture medium to 30°C to inoculate the kasugamycin seed solution with an inoculum volume of 15vol%, and ferment and cultivate.

[0054] (4) Ferment for 170 hours at a fermentation temperature of 28-30°C, ventilation rate of 1:1, stirring speed of 180rpm, and tank pressure of 0.02MPa, and collect and purify the fermentation supernatant to obtain Kasugamycin.

[0055] (5) Take 10mL of fermentation broth in a test tube, adjust the pH to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com