Processing technology of super wear resistant and antibacterial quilt cover fabric

A processing technology and super wear-resistant technology, applied in the field of textile fabrics, can solve the problems of waste of raw materials, complex preparation methods, unreasonable quilt processing technology, etc., and achieve the effect of reducing steps and reducing the time of fabric production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

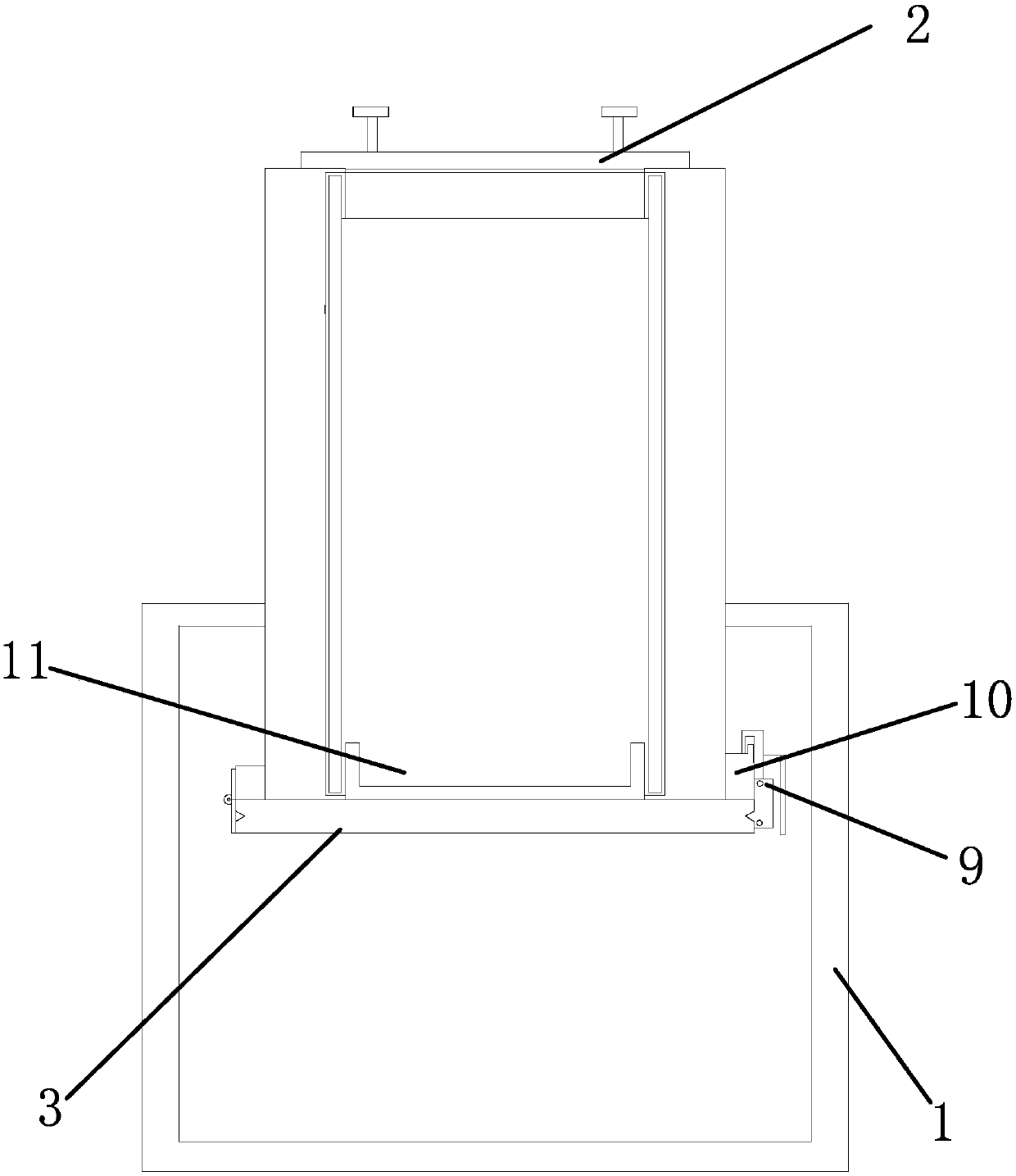

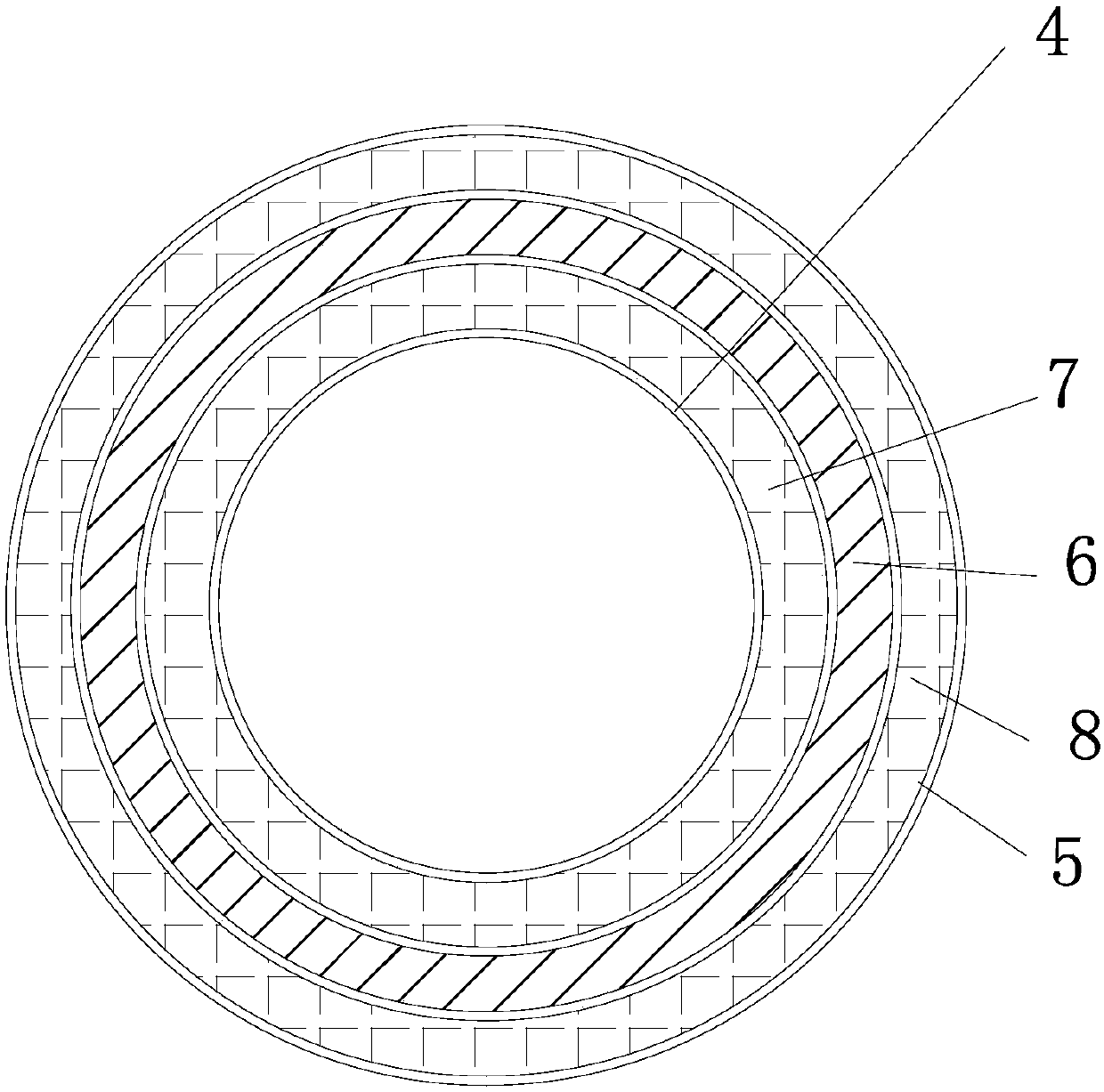

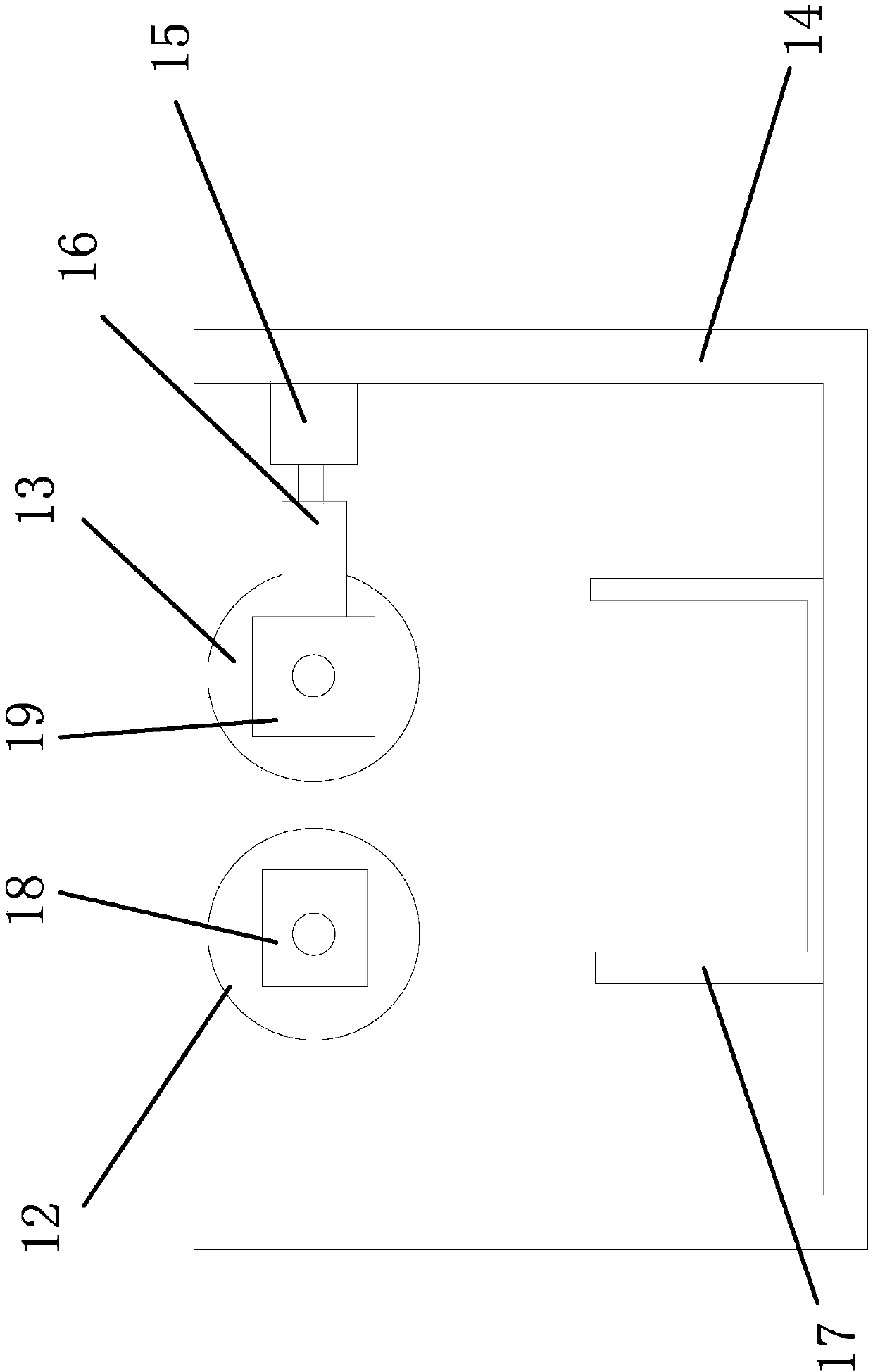

[0052] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0053] A kind of processing technology of super wear-resisting antibacterial quilt cover fabric, comprises the following steps:

[0054] (1), raw material preparation:

[0055] Made from the following raw materials by weight: silk 30, wolfberry 10, ginger 2, mugwort leaves 4, wheat straw 15, lignocellulose 5, soybean protein fiber 8, tea tree essential oil 0.4, calcium carbonate 5, hydrochloric acid 6, tencel 40, nano Zirconia 0.5, paraffin 4, 1-butyl-3-methylimidazole acetate 100, 1-allyl-3-methylimidazolium chloride 98, water 30;

[0056] (2) Preparation and preparation of auxiliary raw materials:

[0057] It is made from the following raw materials by weight: 3 flaxseed oil, 2 diethylenetriamine, 0.4 luteolin, 8 hibis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com