Patents

Literature

33 results about "1-butyl-3-methylimidazolium acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

Nanometer far infrared ceramic fiber woven fabric and production method of nanometer far infrared ceramic fiber woven fabric

ActiveCN104593931AImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsMethacrylateEpoxy

The invention discloses nanometer far infrared ceramic fiber woven fabric. The nanometer far infrared ceramic fiber woven fabric is formed by warp yarns and weft yarns in a woven mode through an air jet loom, and is characterized in that raw materials of the warp yarns and raw materials of the weft yarns comprise, by weight, 27 parts to 33 parts of syndiotactic polypropylene, 10 parts to 14 parts of linear low-density polyethylene, 8 parts to 10 parts of polyurethane films, 16 parts to 22 parts of epoxy resin, 0.4 part to 0.7 part of zinc nitrate, 0.6 part to 0.9 part of magnesium hydrate, 1 part to 3 parts of water glass, 20 parts to 25 parts of nylon yarns, 23 parts to 26 parts of colored cotton fibers, 18 parts to 23 parts of nanometer far infrared ceramic fibers, 21 parts to 24 parts of cellulose acetate fibers, 7 parts to 10 parts of isobutyl methacrylate, 5 parts to 9 parts of peach gum, 1 part to 3 parts of radix bupleuri, 2 parts to 5 parts of fossil fragments, 80 parts to 90 parts of 1-butyl-3-methylimidazolium acetate, 90 parts to 100 parts of 1-allyl-3-methylimidazolium chlorine salt, a proper amount of water and 4 parts to 8 parts of assistants. By means of the nanometer far infrared ceramic fiber woven fabric, the spinnability of plant fibers and the spinning quality are improved, the warmth keeping performance, the wearing resistance, the pilling resistance and the washing resistance of the woven fabric are further improved, and the market prospects are good.

Owner:JIXI YUANDAO AGRI IND TECH

Catechinic acid fiber blended deodorization flame-retardant woven fabric and manufacturing method thereof

ActiveCN104726994AVersatileImprove technical indicatorsFlame-proof filament manufactureMelt spinning methodsFiberPolyethylene glycol

The invention discloses catechinic acid fiber blended deodorization flame-retardant woven fabric. Raw materials of needed warp and needed weft for weaving comprise, by weight, 29 to 35 parts of syndiotactic polypropylene, 18 to 23 parts of polylactic acid, 8 to 12 parts of polyhydroxybutyrate, 3 to 5 parts of montmorillonoid, 0.02 to 0.05 part of canthaxanthin, 0.4 to 0.8 part of diprophylline, 0.5 to 0.9 part of calcium chloride, 23 to 28 parts of catechinic acid fibers, 25 to 30 parts of reed fibers, 18 to 24 parts of flame-retardant fibers, 17 to 23 parts of Lenzing modal fibers, 19 to 27 parts of zein fibers, 7 to 9 parts of oleic acid polyethylene glycol ester, 10 to 14 parts of ethylene glycol monoethyl ether acetate, 3 to 4 parts of peppermint, 2 to 5 parts of isatis roots, 1 to 3 parts of rheum officinale, 85 to 100 parts of 1-butyl-3-methylimidazolium acetate, 95 to 105 parts of 1-allyl-3-methylimidazolium chloride, 4 to 6 parts of auxiliaries and a proper amount of water. The fabric has the advantages of being resistant to odor, flames and abrasion, capable of absorbing sound and isolating heat and the like.

Owner:JIXI YUANDAO AGRI IND TECH

Chinese herbal medicine antibacterial cotton fibers and production method thereof

InactiveCN104278356AHas antibacterial functionHigh strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureEthylene glycol monophenyl etherFiber

The invention discloses Chinese herbal medicine antibacterial cotton fibers. The Chinese herbal medicine antibacterial cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 20-23 parts of cotton fibers, 10-13 parts of modal fibers, 8-10 parts of bamboo pulp fibers, 7-9 parts of banana stem fibers, 5-8 parts of down feather fibers, 1-3 parts of sophora alopecuroide extract powder, 1-2 parts of attapulgite, 0.4-0.8 part of ammonium persulfate, 1.3-3.5 parts of glycine betaine, 18-22 parts of ethylene glycol monophenyl ether, 15-17 parts of benzyl benzoate, 4-5 parts of wild chrysanthemum, 3-4 parts of jasmine flowers, 1-2 parts of lonicera japonica, 100-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 106-110 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the Chinese herbal medicine antibacterial cotton fibers, the operation is simple, the cost is low and the operability is strong; the wild chrysanthemum, jasmine flowers and lonicera japonica are added so that the Chinese herbal medicine antibacterial cotton fibers have an antibacterial function and also have a flower flavor; and meanwhile, various animal and plant fibers are also added to the Chinese herbal medicine antibacterial cotton fibers so that the strength and the heat preservation performance of the cotton fibers are remarkably improved.

Owner:ANHUI SWAN TECH IND GRP

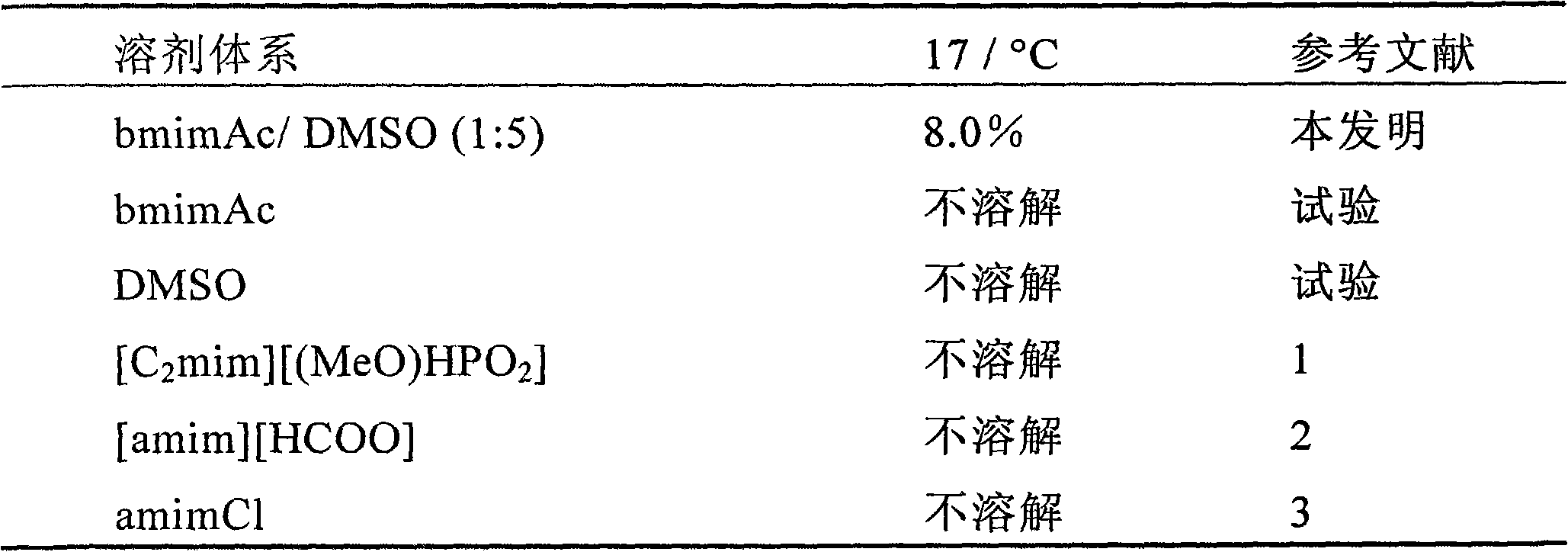

Solvent of cellulose

The invention discloses a solvent of cellulose, and in particular relates to a solvent. The invention aims to provide the solvent of the cellulose, which can dissolve the cellulose at room temperature. The technical proposal comprises that the solvent is a compound solvent of 1-butyl-3-methylimidazolium acetate ion liquid and a dimethyl sulphoxide cosolvent. The mass ratio of the 1-butyl-3-methylimidazolium acetate ion liquid to the dimethyl sulphoxide cosolvent is 2:1-1:5. The solvent is applicable to dissolving the cellulose.

Owner:HENAN NORMAL UNIV

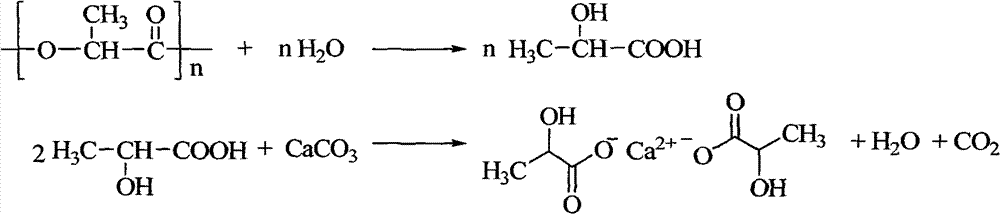

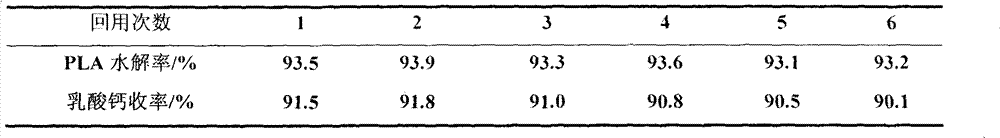

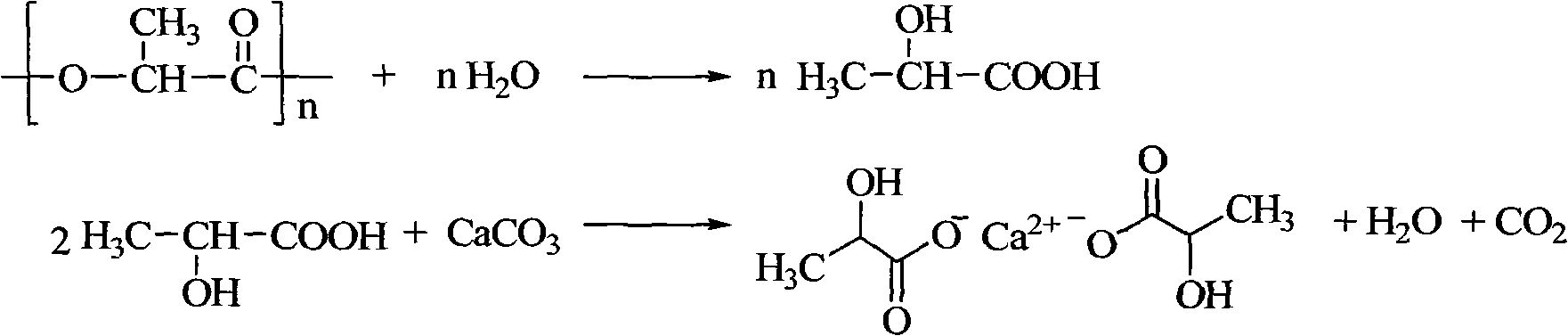

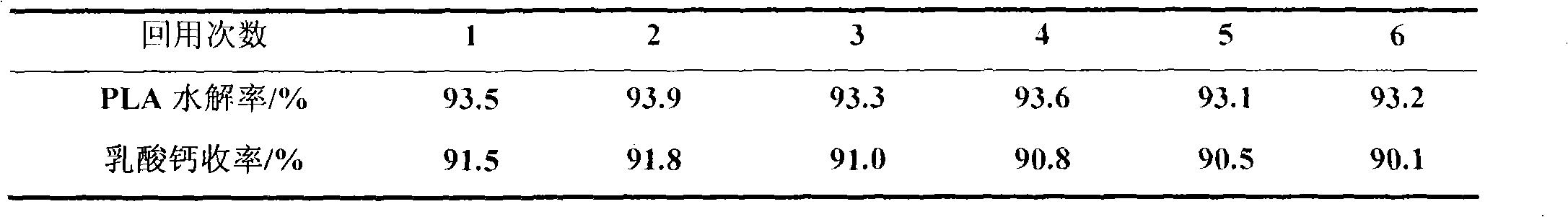

Novel method for recovering calcium lactate by hydrolysis of waste polylactic acid material

ActiveCN102976922AOvercome the non-reusable problemAvoid neutralizing the washing processPreparation from carboxylic acid esters/lactonesCarboxylic acid salt preparationSolubilityDepolymerization

The present invention relates to a novel method for producing calcium lactate by chemical depolymerization of waste polylactic acid materials to realize recovery of the waste polylactic acid material. The method is characterized by using 1-ethyl-3-methylimidazolium acetate and 1-butyl-3-methylimidazolium acetate which have certain solubility and are easy to reuse as a reaction medium and a catalyst; performing a hydrolysis reaction at 110-130 DEG C; adding a certain amount of calcium carbonate after the reaction; filtering; distilling the filtrate under reduced pressure to remove water and then adding an appropriate amount of absolute ethyl alcohol, separating calcium lactate by crystallization, filtering, drying to get calcium lactate, and separating the filtrate by distillation to recover ethanol and ion liquid for recycling and reusing. The yield of calcium lactate is above 90%. Compared with a conventional method, the present invention is characterized by: (1) having no need of using a conventional alkali catalyst, and significantly improving the problems of equipment corrosion and wastewater discharging; and (2) overcoming the problem that the ionic liquid cannot be reused in the background art, because the ionic liquid having a certain solubility for the polylactic acid material is used as the reaction medium and the catalyst, on the one hand the reaction conditions are eased, on the other hand the ionic liquid can be reused.

Owner:QINGDAO UNIV OF SCI & TECH

Woven fabric capable of releasing negative ions and preparation method thereof

InactiveCN105155030AImprove the environmentImprove the defect of single functionConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNoise reductionIon

The invention discloses woven fabric capable of releasing negative ions. The woven fabric is woven by warp yarn and weft yarn through an air jet loom, and the warp yarn and the weft yarn are prepared from raw materials in parts by weight as follows: 25-35 parts of polypropylene resin, 18-22 parts of polyethylene, 1-2 parts of silica, 3-5 parts of tourmaline powder, 15-20 parts of alginate fiber, 18-28 parts of Bamdal fiber, 24-30 parts of fine denier polyamide yarn, 4-5 parts of polyethylene wax, 3-6 parts of methylene diphenyl diisocyanate, 10-14 parts of methyl acrylate, 2-4 parts of folium artemisiae argyi, 3-5 parts of mint, 80-100 parts of 1-butyl-3-methylimidazolium acetate, 100-110 parts of 1-allyl-3-methylimidazolium chloride, an appropriate amount of water and 4-7 parts of an auxiliary. The fabric has multiple functions, can release the negative ions, improves the inner environment of an automobile and has the advantages of noise reduction, thermal insulation, moisture absorption, breathability, wear resistance, waterproofness, pilling resistance and the like, further, the production is simple and easy, and the cost is low.

Owner:安徽省中日农业环保科技有限公司

Down feather composite fibers with jasmine fragrance and preparation method thereof

InactiveCN104294399AAnti-staticAntibacterialConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberNicotiana langsdorffii

The invention discloses down feather composite fibers with a jasmine fragrance, and is characterized in that the down feather composite fibers comprise the following raw materials in parts by weight: 13-16 parts of goose down, 16-21 parts of ox hair, 8-10 parts of glass fibers, 5-8 parts of polynosic, 3-6 parts of conductive fibers, 3-6 parts of jasmine, 1-3 parts of fructus toosendan, 2-4 parts of radix paeoniae rubra, 6-9 parts of mineral wool fibers, 18-22 parts of tobacco straws, 1.2-3.1 parts of triethyl acetyl citrate, 2.1-3.2 parts of propyl acetate, 0.2-0.5 parts of triethyl citrate, 0.6-1.4 parts of a nano pearl powder, 100-110 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 3-5 parts of an auxiliary agent, and a proper amount of water. With addition of jasmine, fructus toosendan, radix paeoniae rubra and other components, the down feather composite fibers not only have the jasmine fragrance, but also can effectively remove dirt on the feather composite fibers, and have better conditioning and nursing effects on down feather; and the prepared down feather composite fibers have the advantages of static electricity resistance, large elasticity, good filling power, bacteria resistance, bacteriostasis, wash durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Washable light down feather composite fiber and preparation method thereof

InactiveCN104278355AIncrease profitLow costConjugated cellulose/protein artificial filamentsArtifical filament manufactureRhizomeMaterials science

The invention discloses a washable light down feather composite fiber. The washable light down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 12-14 parts of goose down, 15-20 parts of pig hair, 14-17 parts of camel hair, 6-8 parts of plumetis fibers, 10-12 parts of tencel fibers, 7-9 parts of cheviot fibers, 2.1-3.3 parts of sorbitol, 1.2-3.4 parts of glycerol monolaurate, 10-13 parts of grapevine, 1.2-3.1 parts of citric acid, 2-4 parts of phellodendron amurense, 1-3 parts of white atractylodes rhizome, 2-3 parts of the root bark of white mulberry, 0.3-0.5 part of magnesium chloride, 3-5 parts of oxidized castor oil, 100-120 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 1-3 parts of assistants and an appropriate amount of water. According to the washable light down feather composite fiber, the pig hairs and the camel hairs are added, and therefore, the feather utilization rate is increased and the cost is reduced; and the phellodendron amurense, the white atractylodes rhizome, the root bark of white mulberry and other Chinese herbal medicines are added, so that the washable light down feather composite fiber has the advantages of health keeping, sterilization, excellent breathability, washing durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Cotton fibers capable of releasing far infrared negative ions and production method of cotton fibers

InactiveCN104278357AGood antibacterial effectAntibacterial, anti-mite and flame retardantConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNano al2o3Staphylococcus aureus

The invention discloses cotton fibers capable of releasing far infrared negative ions. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 20-23 parts of cotton fibers, 7-9 part of active carbon fibers, 6-10 parts of camel hair fiber, 10-12 parts of ramie fibers, 5-7 parts of polypropylene fibers, 3-5 parts of fructus xanthii extract, 2-4 parts of far infrared negative ion powder, 1-2 parts of nano aluminum oxide, 1-3 parts of medical stones, 2.1-3.5 parts of hot melt adhesive powder, 15-18 parts of C12 alcohol polyoxyethylene ether, 9-12 parts of citric acid, 12-15 parts of monoacetin, 2-4 parts of divaricate saposhnikovia root, 1-3 parts of isatis tinctoria, 100-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-105 parts of 1-butyl-3-methylimidazolium acetate, 4-6 parts of an addition agent and a proper amount of water. According to the cotton fibers capable of releasing the far infrared negative ions, the fructus xanthii extract is added into the raw materials by using an ultrasonic technology and has a good bacterium inhibition effect on staphylococcus aureus; and meanwhile, active ingredients including the far infrared negative ion powder, divaricate saposhnikovia root, isatis tinctoria and the like are added so that the prepared cotton fibers can release the negative ions beneficial to a human body and also have the effects of resisting bacteria, preventing mites, retarding flame and the like.

Owner:ANHUI SWAN TECH IND GRP

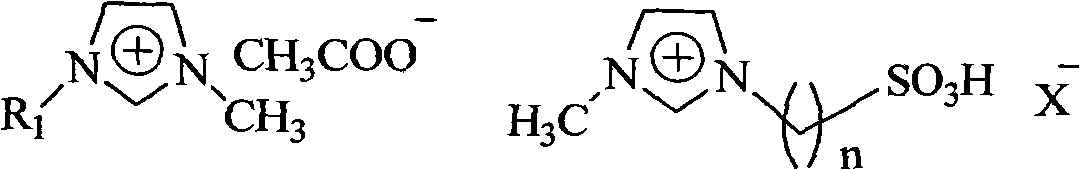

Cellulose dissolving agent and application of cellulose dissolving agent in aspect of cellulose esterification modification

InactiveCN104788691AIncrease concentrationAchieve maximum recoveryBulk chemical productionDegree of substitutionReaction step

The invention relates to a cellulose dissolving agent and application of the cellulose dissolving agent in the aspect of cellulose esterification modification. The cellulose dissolving agent is prepared from the following constituents: 1-butyl-3-methylimidazolium acetate, ammonium tetrabutyl acetate and N,N'-dimethylacetamide. According to the invention, in the novel solvent, a homogeneous phase modification method is conducted to enable paratoluensulfony chloride to directly react with pulp board cellulose dissolved by the cellulose dissolving agent, the intermediate reaction step can be avoided, the reaction conditions can be controlled to regulate the degree of substitution of the pulp board cellulose on toluenesulfonate; the process is simple, the production cost is low, and the high purity is achieved.

Owner:BEIJING FORESTRY UNIVERSITY

3D printing chitosan material using ionic liquid as medium, and preparation method thereof

ActiveCN110330697ARealize 3D modelingValid matchAdditive manufacturing apparatusChloride1-allyl-3-methylimidazolium bromide

The present invention relates to a 3D printing chitosan material using an ionic liquid as a medium, and a preparation method and an application thereof. The medium comprises at least an ionic liquid,and the ionic liquid is at least one of 1-allyl-3-methylimidazolium bromide, 1-allyl-3-methylimidazolium chloride, 1-ethyl-3-methylimidazolium chloride, 1-butyl-3-methylimidazolium chloride, 1-butyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium dimethylphosphate and 1-carboxymethyl-3-methylimidazolium chloride. The 3D printing chitosan material usingthe ionic liquid as the medium has the advantages of effective realization of the three-dimensional molding of the chitosan material, simple steps, simplicity in operation, and designing and preparation of a three-dimensional chitosan functional material with different forms as needed.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

Waterproof insulation multifunctional woven fabric and manufacturing method thereof

InactiveCN105155091AVersatileWith waterproof insulationConjugated cellulose/protein artificial filamentsWoven fabricsIsooctyl acrylateMoisture absorption

The invention discloses a waterproof insulation multifunctional woven fabric. The waterproof insulation multifunctional woven fabric is composed of warp yarns and weft yarns which are woven by an air-jet loom. The raw materials of the warp yarns and the weft yarns are made from the following components, by weight, 28 to 36 parts of syndiotactic polypropylene, 10 to 15 parts of polyurethane foam, 0.3 to 0.6 part of antioxidant RD, 4 to 8 parts of paraffin, 23 to 28 part of polyacrylonitrile fiber, 20 to 25 parts of shengma fiber, 22 to 26 parts of bamboo charcoal fiber, 15 to 19 part of pomegranate rind slurry, 2 to 4 parts of zeolite molecular sieve, 1 to 2 parts of potassium tartrate, 5 to 8 parts of 2-(dimethylamino) ethyl acrylate, 10 to 15 parts of 2-ethylhexyl acrylate, 1 to 4 parts of phellodendron, 2 to 5 parts of ash bark, 89 to 110 parts of 1-butyl-3-methylimidazolium acetate, 95 to 115 parts of 1- allyl-3-methylimidazolium bromide, a proper amount of water and 5 to 7 parts of auxiliary agent. The waterproof insulation multifunctional woven fabric is waterproof, heat insulating, stinking-proof, flame retardant, antibiosis and mildew-resistant, and good in moisture absorption and permeability and can distinctly purify environment in a car compared with the prior art. .

Owner:安徽省中日农业环保科技有限公司

Antibacterial warm-keeping cotton fiber with seaweed carbon fibers added and preparation method of cotton fiber

InactiveCN104357949AInsufficient improvementSimple processConjugated cellulose/protein artificial filamentsSpinning solutions preparationCarbon fibersAdditive ingredient

The invention discloses an antibacterial warm-keeping cotton fiber with seaweed carbon fibers added. The cotton fiber is characterized by being prepared from raw materials in parts by weight as follows: 20-30 parts of cotton fibers, 12-14 parts of coconut cotton fibers, 10-13 parts of bamboo fibers, 12-14 parts of the seaweed carbon fibers, 9-11 parts of wool fibers, 2-4 parts of xanthan gum, 4-6 parts of a hydroxyl silicone oil emulsion, 8-10 parts of potato straw, 1.2-2.4 parts of zirconium phosphate, 0.4-0.8 parts of sodium sulfite, 22-25 parts of ethylene glycol butyl ether, 15-18 parts of tetraethyl orthosilicate, 2-3 parts of Chinese angelica, 1-3 parts of poria cocos, 3-5 parts of Chinese magnoliavine fruits, 110-120 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 105-100 parts of 1-butyl-3-methylimidazolium acetate, 4-6 parts of an additive and a proper amount of water. The cotton fiber is simple in process and convenient to operate, the seaweed carbon fibers are added, and far infrared rays beneficial to human bodies can be released; meanwhile, other animal and plant fibers and Chinese herbal medicine ingredients are also added, so that defects of natural cotton fibers are overcome, and the cotton fiber has the advantages of bacterium resistance, mildew prevention, high toughness, high strength, high warm-keeping property and the like.

Owner:安徽颍元农业科技股份有限公司

Multi-fiber composite wear-resistant anti-microbial woven fabric and manufacturing method for same

InactiveCN105155092AImprove spinnabilityImprove spinning qualityConjugated cellulose/protein artificial filamentsWoven fabricsFiberWear resistant

The invention discloses a multi-fiber composite wear-resistant anti-microbial woven fabric. The multi-fiber composite wear-resistant anti-microbial woven fabric is composed of warp yarns and weft yarns which are woven by an air-jet loom. The raw materials of the warp yarns and the weft yarns are made from the following components, by weight, 30 to 33 parts of polypropylene, 20 to 25 parts of down feather, 23 to 26 parts of terylene, 24 to 28 parts of chicken feather, 16 to 19 parts of shengma fiber, 13 to 17 parts of acetate rayon, 2 to 4 parts of bentonite, 0.3 to 0.5 part of zinc oxide, 0.7 to 0.9 part of nanometer zirconia powder, 3 to 6 parts of mercaptoacetic acid, 7 to 10 parts of n-Propyl acrylate, 6 to 9 parts of dipropylene glycol dibenzoate, 3 to 5 parts of ginger, 2 to 4 parts of burdock, 85 to 95 parts of 1-butyl-3-methylimidazolium acetate, 90 to 110 parts of 1- allyl-3-methylimidazolium bromide, a proper amount of water, and 5 to 8 parts of auxiliary agent. The multi-fiber composite wear-resistant anti-microbial woven fabric can be used for automotive trims, and is stiff and smooth in appearance and fashionable.

Owner:安徽省中日农业环保科技有限公司

Thermal and wear resistant mercerized wool woven fabric and manufacturing method thereof

InactiveCN105133078AWarm and wear-resistantSound-absorbing and antibacterialWoven fabricsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention discloses thermal and wear resistant mercerized wool woven fabric which is prepared from the following raw materials in parts by weight: 31-36 parts of isotactic polypropylene, 16-19 parts of chloroprene rubber, 0.3-0.8 part of aluminum sulfate, 0.7-1.2 parts of barium sulfate, 1.2-3.2 parts of salicylanilide, 2-4 parts of diatomite, 20-30 parts of mercerized wool, 23-27 parts of polyester fiber, 18-24 parts of apocynum venetum fiber, 19-26 parts of Anti-fcell, 2.4-3.6 parts of polyvinyl alcohol, 7-10 parts of 2-ethylhexyl epoxystearate, 11-14 parts of dibutyl ester, 3-5 parts of pinellia ternate, 2-4 parts of radix aucklandiae, 105-110 parts of 1-butyl-3-methylimidazolium acetate, 95-110 parts of 1-allyl-3-methylimidazolium chloride, 4-6 parts of an assistant and a proper amount of water. According to the thermal and wear resistant mercerized wool woven fabric and the manufacturing method thereof, provided by the invention, the conventional preparation technology is changed, the prepared woven fabric has the characteristics of warmth retention, wear resistance, sound absorption, antibacterial property, comfortableness, softness, and high convenience in dyeing and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Acid/base-resistant cotton fiber and preparation method thereof

InactiveCN104357950AGood acid and alkali resistanceImprove antibacterial propertiesConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsBenzoic acidSandalwood oil

The invention discloses an acid / base-resistant cotton fiber. The cotton fiber is characterized by being prepared from raw materials in parts by weight as follows: 18-24 parts of long staple cotton fibers, 7-9 parts of polypropylene fibers, 10-13 parts of straw fibers, 6-8 parts of copper ammonia fibers, 1.2-4.3 parts of carboxymethyl cellulose, 13-15 parts of bagasse, 0.7-1.2 parts of ammonium stearate, 0.6-0.9 parts of zinc oxide, 3-6 parts of sandalwood oil, 18-24 parts of toluene diisocynate, 17-23 parts of diethylene glycol, 12-14 parts of benzoic acid, 2-3 parts of common jasminorange sawdust, 1-4 parts of radix astragali, 3-5 parts of lightyellow sophora roots, 100-110 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 104-112 parts of 1-butyl-3-methylimidazolium acetate, 4-6 parts of an additive and a proper amount of water. The production technology is improved, and the polypropylene fibers, the copper ammonia fibers, the common jasminorange sawdust, the radix astragali, the lightyellow sophora roots and the like are added, so that the acid / base resistance and the insect-preventing and antibacterial effects of the cotton fiber are improved.

Owner:安徽颍元农业科技股份有限公司

Light cotton fibers with moth-proof and mold-proof effects and production method of light cotton fibers

InactiveCN104278358AEasy to operateEasy to controlConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsMaterials science1-butyl-3-methylimidazolium acetate

The invention discloses light cotton fibers with moth-proof and mold-proof effects. The light cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 18-23 parts of cotton fibers, 10-12 parts of ramie fibers, 8-10 parts of kapok fibers, 5-7 parts of acrylic fibers, 7-9 parts of Richcel fibers, 2.1-3.4 parts of chitin, 4-6 parts of semen pharbitidis extract, 0.6-0.9 part of nano magnesium oxide, 2-3 parts of straw wood charcoal, 1.1-3.2 parts of acrylamide, 0.5-0.8 part of hexadecyl trimethyl ammonium bromide, 14-16 parts of polyacrylic acid, 17-19 parts of secondary alcohol polyoxyethylene ether, 2-4 parts of celery oil, 1-3 parts of scutellaria baicalensis, 2-3 parts of sophora flavescens, 3-4 parts of houttuynia cordata, 95-105 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 100-110 parts of 1-butyl-3-methylimidazolium acetate, 3-5 parts of an addition agent and a proper amount of water. According to the light cotton fibers with the moth-proof and mold-proof effects, the operation is simple and is easy to control; the production efficiency and the product quality are high; the semen pharbitidis extract is added into raw materials by adopting an ultrasonic technology; and meanwhile, active components including nano magnesium oxide, sophora flavescens, scutellaria baicalensis and the like are added so that the light cotton fibers have the advantages of excellent moth-proof and mold-proof effects, excellent flame retardant efficiency, strong wear resistance, high heat preservation property, light weight, softness and the like.

Owner:ANHUI SWAN TECH IND GRP

Cotton fiber for heat-insulating and sound-absorbing materials for buildings and producing method of cotton fiber

InactiveCN104357951ACause harmImprove antibacterial propertiesConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberSlag

The invention discloses a cotton fiber for heat-insulating and sound-absorbing materials for buildings. The cotton fiber is characterized by being prepared from raw materials in parts by weight as follows: 19-26 parts of slag cotton fibers, 12-15 parts of regenerated cotton fibers, 11-13 parts of waste paper fibers, 2-4 parts of zirconium silicate powder, 1-2 parts of meerschaum, 0.6-1.1 parts of zinc borate, 0.3-0.6 parts of chlorothalonil, 17-19 parts of propylene glycol monomethyl ether, 9-12 parts of ethanol diethyl ether acetate, 0.5-0.8 parts of manganese naphthenate, 4.3-6.1 parts of white oil, 2-4 parts of lavender, 1-3 parts of rosemary, 90-100 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 100-110 parts of 1-butyl-3-methylimidazolium acetate, 4-7 parts of an aid and a proper amount of water. A producing method of the cotton fiber is simple and practical, energy is saved, secondary pollution is not caused easily, no harm is caused to the environment, the slag cotton fibers and the waste paper fibers are fully used, the problem of treatment of solid waste is solved, the chlorothalonil, the white oil, the lavender, the rosemary and the like are added, the antibacterial, mothproof and heat-insulating performance of the cotton fiber is improved, and the cotton fiber can be widely applied to preparation of the heat-insulating and sound-absorbing materials for the buildings.

Owner:安徽颍元农业科技股份有限公司

Method for concentrating aniline from water solution

InactiveCN101709035AStrong separation and enrichment abilityPracticalAmino compound purification/separationAniline1-ethyl-3-methylimidazolium tetrafluoroborate

The invention relates to a method for concentrating aniline from water solution, which belongs to the field of chemical concentration, and the method comprises the following steps: using 1.03% of aniline water solution at normal temperature and normal pressure, and taking a solid inorganic salt or ionic liquid as an additive, and taking methyl tertiary butyl ether as an extractant, wherein the solid inorganic salt is sodium chloride, sodium bromide, potassium carbonate or potassium acetate, the ionic liquid is 1-ethyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium tetrafluoroborate, 1-butyl-3-methylimidazolium acetate or 1-octyl-methylimidazolium acetate, the adding amount of the solid inorganic salt is 5%-30% (weight percentage) of the aniline water solution, the adding amount of the ionic liquid is 5%-20% (weight percentage) of the aniline water solution, and the adding amount of the extractant is 6:1 in comparison with the aniline water solution. The method can effectively enrich and concentrate low concentration aniline in water and improve the detection technology.

Owner:BEIJING UNIV OF CHEM TECH

Cotton fiber with good yellowing resistance and preparation method thereof

InactiveCN104357947AGood sweat absorptionEliminate stuffinessConjugated cellulose/protein artificial filamentsArtifical filament manufactureDibutyl phosphateGlyceryl monostearate

The invention discloses a cotton fiber with good yellowing resistance. The cotton fiber is characterized by being prepared from raw materials in parts by weight as follows: 19-23 parts of fine cotton fibers, 11-13 parts of soybean fibers, 8-9 parts of spun silk fibers, 7-10 parts of cattail fibers, 6-11 parts of moxa, 3-5 parts of nanometer chitin, 19-23 parts of methoxypolyethylene glycol, 12-14 parts of glyceryl monostearate, 3-4 parts of hops, 2-4 parts of ginkgo leaves, 1-3 parts of borax, 4-6 parts of dimethicone, 100-110 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 105-110 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an additive and a proper amount of water. The added borax is a very good water softener, and the added chitin can greatly improve the sweat absorption of a fabric and effectively eliminate stuffiness and stickiness of clothes, so that the cotton fabric made of the cotton fiber has characteristics that the cotton fabric is excellent in antibacterial effect and washable, cannot turn yellow easily and the like.

Owner:安徽颍元农业科技股份有限公司

Processing technology of super wear resistant and antibacterial quilt cover fabric

InactiveCN107829195ACan't grindShorten the timeConjugated cellulose/protein artificial filamentsWoven fabricsFiberWear resistant

The invention provides a processing technology of super wear resistant and antibacterial quilt cover fabric, and belongs to the technical field of textile fabric. The processing technology solves thetechnical problems that an existing processing technology of the super wear resistant and antibacterial quilt cover fabric is complex in process and the like. The processing technology of the super wear resistant and antibacterial quilt cover fabric is characterized by comprising the following steps of 1, preparing raw materials, wherein the raw materials comprise, by weight, 30-35 parts of silk,10-12 parts of medlar, 2-3 parts of fresh ginger, 4-5 parts of folium artemisiae argyi, 15-20 parts of wheat straw, 5-6 parts of lignocellulose, 8-9 parts of soybean protein fiber, 0.4-0.5 part of teatree essential oil, 5-6 parts of calcium carbonate, 6-7 parts of hydrochloric acid, 40-50 parts of tencel, 0.5-0.6 part of nano-zirconia, 4-6 parts of paraffin, 100-110 parts of 1-butyl-3-methylimidazolium acetate, 98-105 parts of 1-propylene-3-methylimidazolium chloride and 30-40 parts of water. The processing technology of the super wear resistant and antibacterial quilt cover fabric has the advantage of being high in processing efficiency.

Owner:海宁市成达经编股份有限公司

Supercritical carbon dioxide ionic liquid degumming method for apocynum venetum bast fibers

The invention discloses a supercritical carbon dioxide ionic liquid degumming method for apocynum venetum bast fibers. The supercritical carbon dioxide ionic liquid degumming method includes the steps that ionic-liquid and ethyl-alcohol degumming liquid is prepared by 1-butyl-3-methylimidazolium acetate ionic liquid and ethyl alcohol in the mass ratio of 10:1 to 1:1 and placed into a degumming reactant container, processing is carried out for 120 min to 240 min under the conditions that the pressure is 15 MPa to 30 MPa, the temperature is 80 DEG C to 120 DEG C, and a bin cage carries out autorotation at the speed of 30 r / min to 60 r / min, pressure releasing is carried out, and the apocynum venetum fibers are obtained. According to the degumming method, water is avoided, ionic liquid and carbon dioxide generated after using can be recycled, the gumming speed is high, the residual gum rate is lower than 8%, and the level of the existing degumming technology is achieved.

Owner:晋江国盛新材料科技有限公司

A method for reducing residual ink in black and white laser printing waste paper deinking pulp

ActiveCN106283797BReduce the binding forceReduce volumePaper recyclingPulp bleachingFiberLithium hydroxide

The invention relates to a method for reducing residual ink of black and white laser printing wastepaper deinked pulp. The method comprises the following steps: adding a mixed solvent prepared by combination of 1-butyl-3-methylimidazolium acetate and LiNO3 .2H2O into black and white laser printing wastepaper; then, adding lipase and lithium hydroxide, uniformly mixing chemicals and wastepaper with a medium-rich mixer, heating the mixed material to a preset temperature, and performing ultrasonic treatment to a preset time; and beating, washing and deinking the treated materials, leading a cleaning solution to flow into a solvent recycling system, and recycling the reclaimed solvent. The method can be used for effectively swelling fibers of black and white laser printing wastepaper and weakening the connection between fibers and black and white laser printing ink particles, so that the ink particles of black and white laser printing wastepaper can be effectively removed, the physical strength and optical performance of finished paper can be improved, the product quality of deinked pulp can be promoted, and environment-friendly processing of wastepaper fibers can be realized since the adopted mixed solvent has stable properties and can be easily reclaimed.

Owner:QILU UNIV OF TECH

Natural plant antibacterial cashmere composite fabric having skincare healthcare effect and production method of natural plant antibacterial cashmere composite fabric

InactiveCN106835704AGood antibacterialImproves UV protectionCarbon fibresBiochemical fibre treatmentBetaineSilanes

The invention discloses a natural plant antibacterial cashmere composite fabric having a skincare healthcare effect. The natural plant antibacterial cashmere composite fabric is prepared from the following raw materials in parts by weight: 34 to 36 parts of Australian cashmere, 12 to 15 parts of aramid fiber, 17 to 19 parts of black bamboo charcoal fibers, 8 to 10 parts of cottonrose hibiscus stem and peel pectin, 32 to 33 parts of 40 percent (owf) natural sericin solution, 0.2 to 0.4 part of sodium sulfate, 5 to 6 parts of pineapple protein powder, 1.5 to 1.8 parts of dodecyldimethyl betaine, 3 to 5 parts of nano calcium carbonate, 1.2 to 1.6 parts of amino silane, 0.1 to 0.3 part of lemon essential oil, 170 to 190 parts of 1-butyl-3-methylimidazolium acetate, and an appropriate amount of water. By optimizing formula and improving the production process, the cashmere composite fiber is prepared by virtue of a wet-method spinning process, the antibacterial performance, anti-ultraviolet performance and anti-shrinking performance of the cashmere can be improved by virtue of the soaking treatment of a mixed finishing solution, the prepared cashmere composite fabric has the characteristics of cashmere and araid fibers, and is natural and soft, and has a skincare effect.

Owner:倪进培

Method for concentrating aniline from water solution

InactiveCN101709035BAmino compound purification/separationAniline1-ethyl-3-methylimidazolium tetrafluoroborate

The invention relates to a method for concentrating aniline from water solution, which belongs to the field of chemical concentration, and the method comprises the following steps: using 1.03% of aniline water solution at normal temperature and normal pressure, and taking a solid inorganic salt or ionic liquid as an additive, and taking methyl tertiary butyl ether as an extractant, wherein the solid inorganic salt is sodium chloride, sodium bromide, potassium carbonate or potassium acetate, the ionic liquid is 1-ethyl-3-methylimidazolium acetate, 1-ethyl-3-methylimidazolium tetrafluoroborate,1-butyl-3-methylimidazolium acetate or 1-octyl-methylimidazolium acetate, the adding amount of the solid inorganic salt is 5%-30% (weight percentage) of the aniline water solution, the adding amount of the ionic liquid is 5%-20% (weight percentage) of the aniline water solution, and the adding amount of the extractant is 6:1 in comparison with the aniline water solution. The method can effectively enrich and concentrate low concentration aniline in water and improve the detection technology.

Owner:BEIJING UNIV OF CHEM TECH

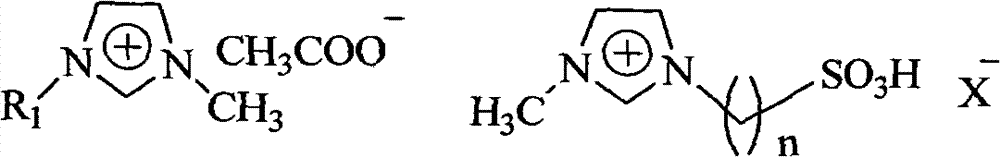

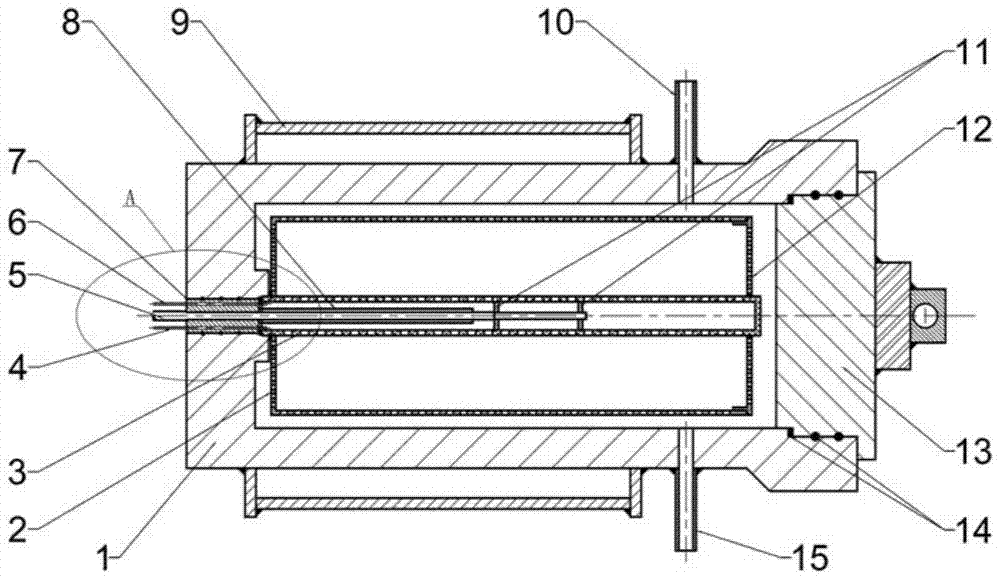

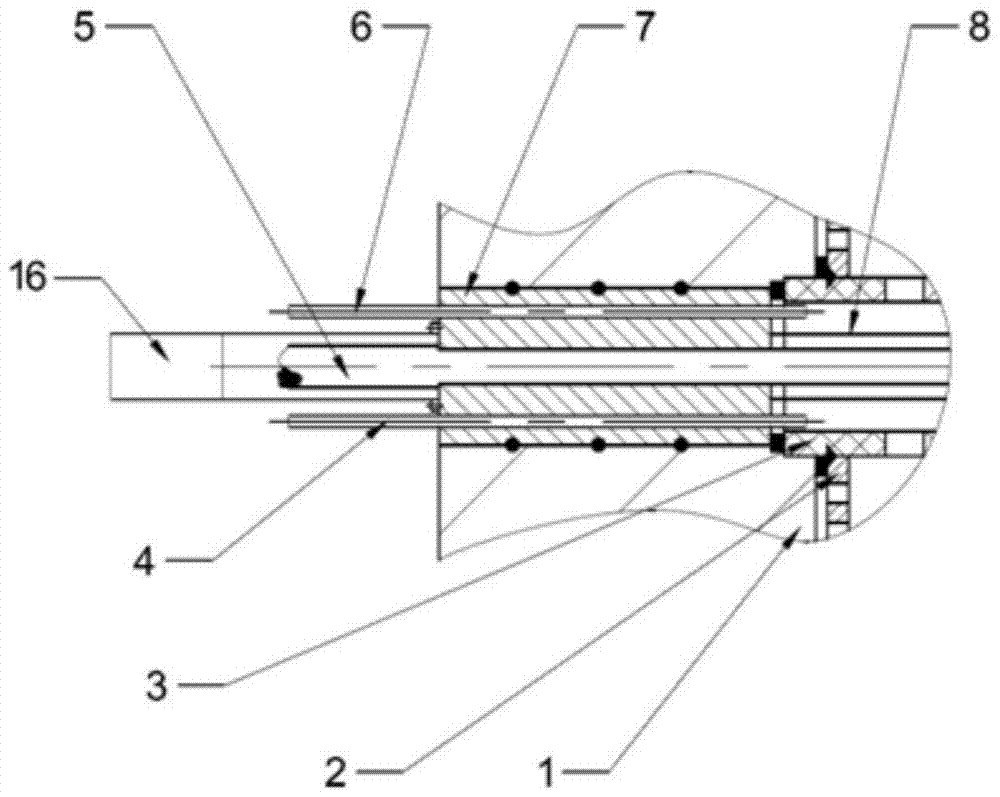

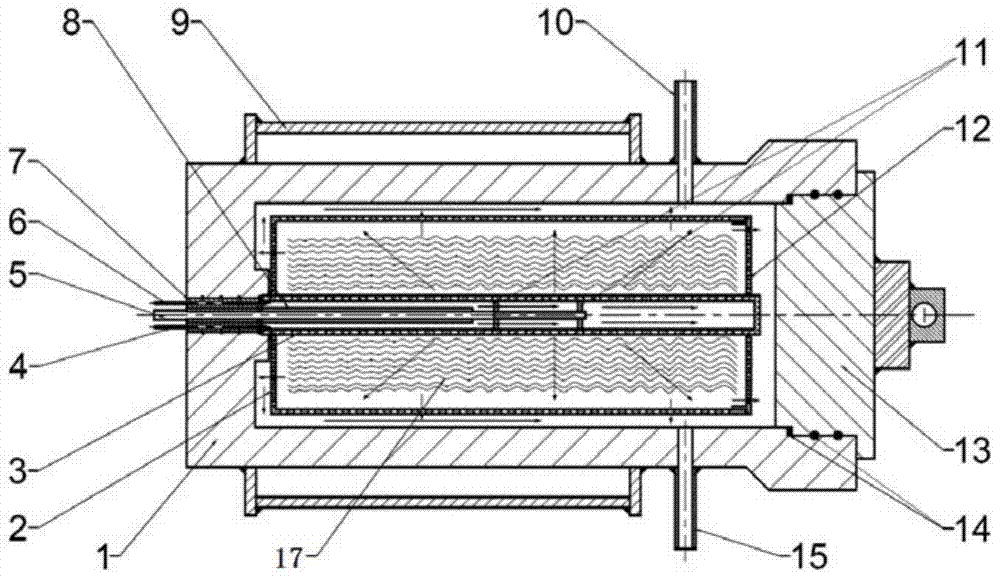

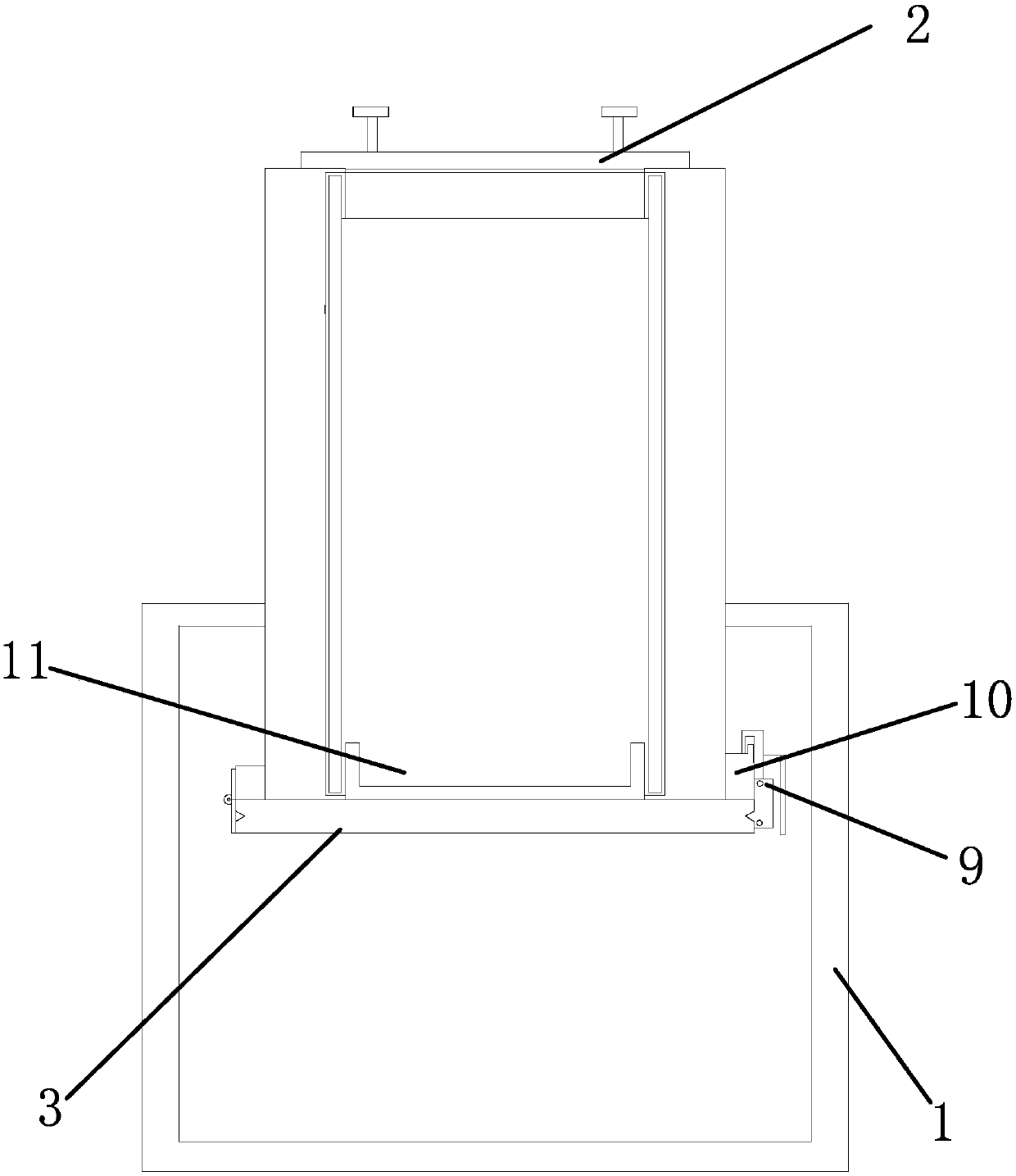

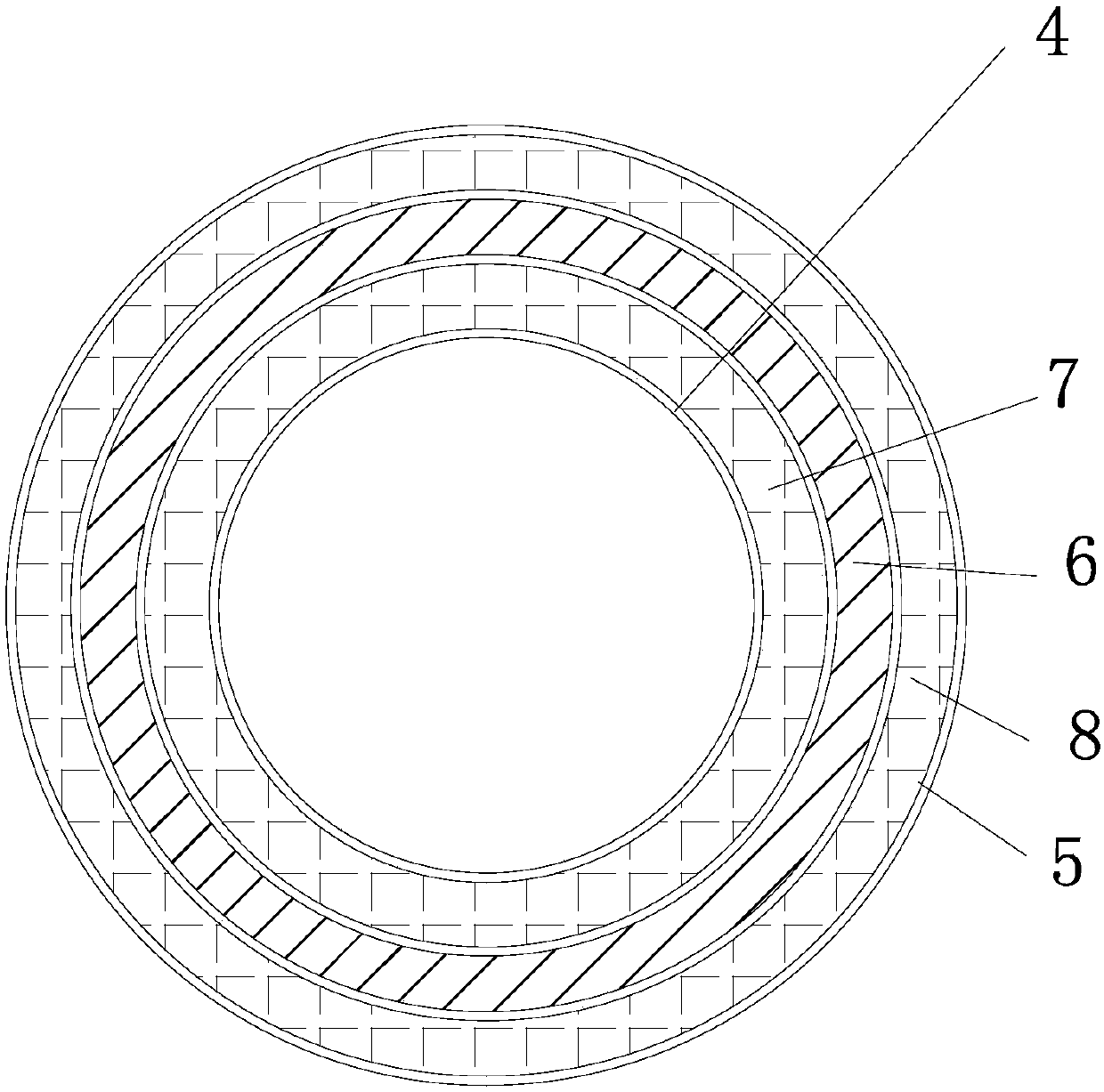

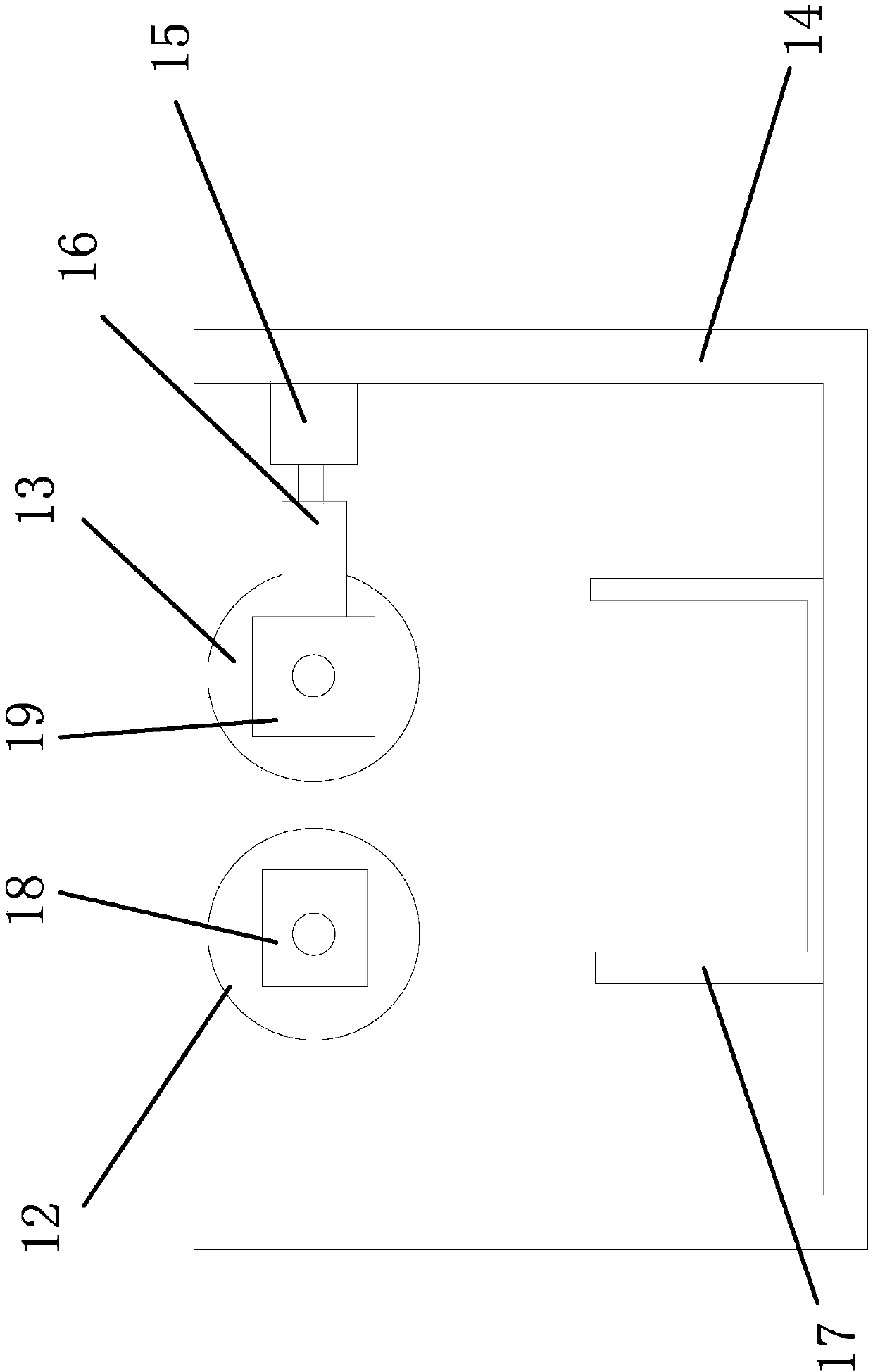

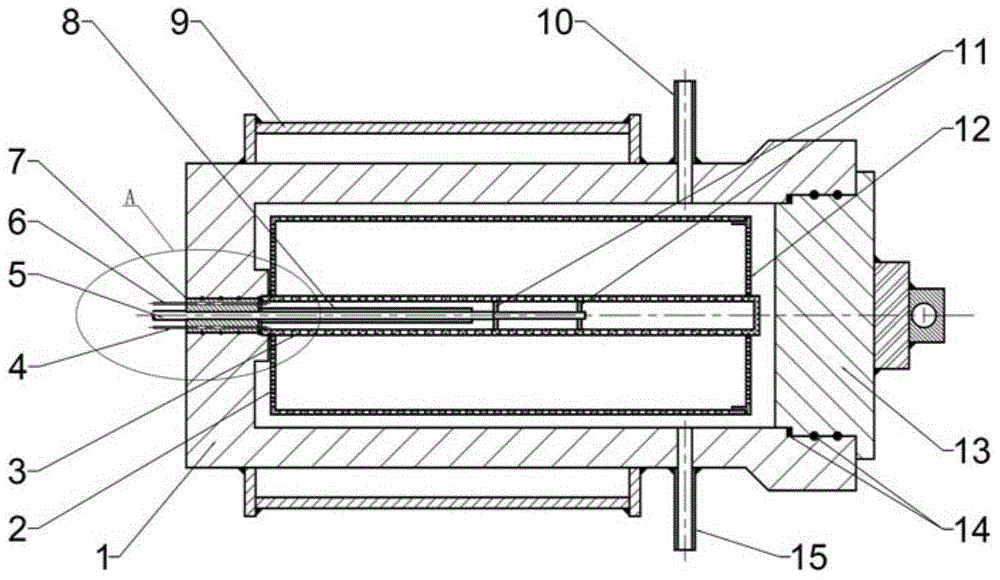

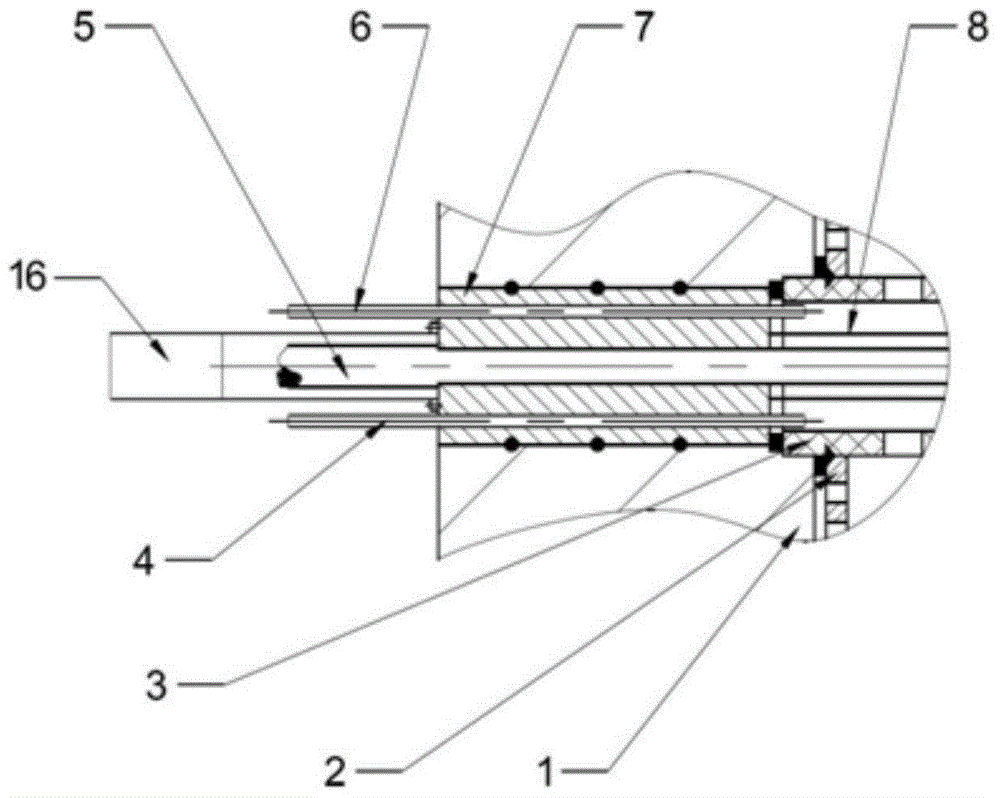

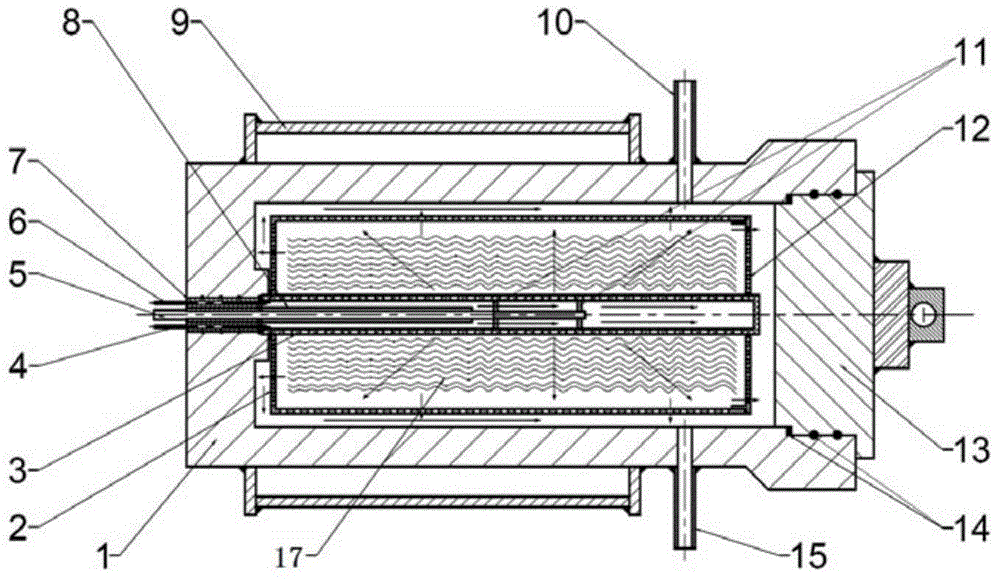

A kind of viscosity control method based on 1-butyl-3-methylimidazole acetate [bmim][oac] carbon dioxide absorbent

ActiveCN103736382BLow viscosityIncrease absorption rateDispersed particle separationAir quality improvementViscosity modifier1-butyl-3-methylimidazolium acetate

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Novel method for recovering calcium lactate by hydrolysis of waste polylactic acid material

ActiveCN102976922BPreparation from carboxylic acid esters/lactonesCarboxylic acid salt preparationSolubilityDepolymerization

Owner:QINGDAO UNIV OF SCI & TECH

A kind of supercritical carbon dioxide ionic liquid degumming method of apocynum bast fiber

Owner:晋江国盛新材料科技有限公司

Method for reducing residual ink of black and white laser printing wastepaper deinked pulp

ActiveCN106283797AReduce the binding forceReduce volumePaper recyclingPulp bleachingFiberLithium hydroxide

The invention relates to a method for reducing residual ink of black and white laser printing wastepaper deinked pulp. The method comprises the following steps: adding a mixed solvent prepared by combination of 1-butyl-3-methylimidazolium acetate and LiNO3 .2H2O into black and white laser printing wastepaper; then, adding lipase and lithium hydroxide, uniformly mixing chemicals and wastepaper with a medium-rich mixer, heating the mixed material to a preset temperature, and performing ultrasonic treatment to a preset time; and beating, washing and deinking the treated materials, leading a cleaning solution to flow into a solvent recycling system, and recycling the reclaimed solvent. The method can be used for effectively swelling fibers of black and white laser printing wastepaper and weakening the connection between fibers and black and white laser printing ink particles, so that the ink particles of black and white laser printing wastepaper can be effectively removed, the physical strength and optical performance of finished paper can be improved, the product quality of deinked pulp can be promoted, and environment-friendly processing of wastepaper fibers can be realized since the adopted mixed solvent has stable properties and can be easily reclaimed.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A kind of viscosity control method based on 1-butyl-3-methylimidazole acetate [bmim][oac] carbon dioxide absorbent A kind of viscosity control method based on 1-butyl-3-methylimidazole acetate [bmim][oac] carbon dioxide absorbent](https://images-eureka.patsnap.com/patent_img/87ca0d8a-162a-4f93-8878-951fcc44ae2a/HDA0000447822550000011.png)

![A kind of viscosity control method based on 1-butyl-3-methylimidazole acetate [bmim][oac] carbon dioxide absorbent A kind of viscosity control method based on 1-butyl-3-methylimidazole acetate [bmim][oac] carbon dioxide absorbent](https://images-eureka.patsnap.com/patent_img/87ca0d8a-162a-4f93-8878-951fcc44ae2a/HDA0000447822550000012.png)

![A kind of viscosity control method based on 1-butyl-3-methylimidazole acetate [bmim][oac] carbon dioxide absorbent A kind of viscosity control method based on 1-butyl-3-methylimidazole acetate [bmim][oac] carbon dioxide absorbent](https://images-eureka.patsnap.com/patent_img/87ca0d8a-162a-4f93-8878-951fcc44ae2a/HDA0000447822550000021.png)