Solvent of cellulose

A cellulose and solvent technology, applied in the field of solvents, can solve problems such as toxicity, harsh operating conditions, and cellulose degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

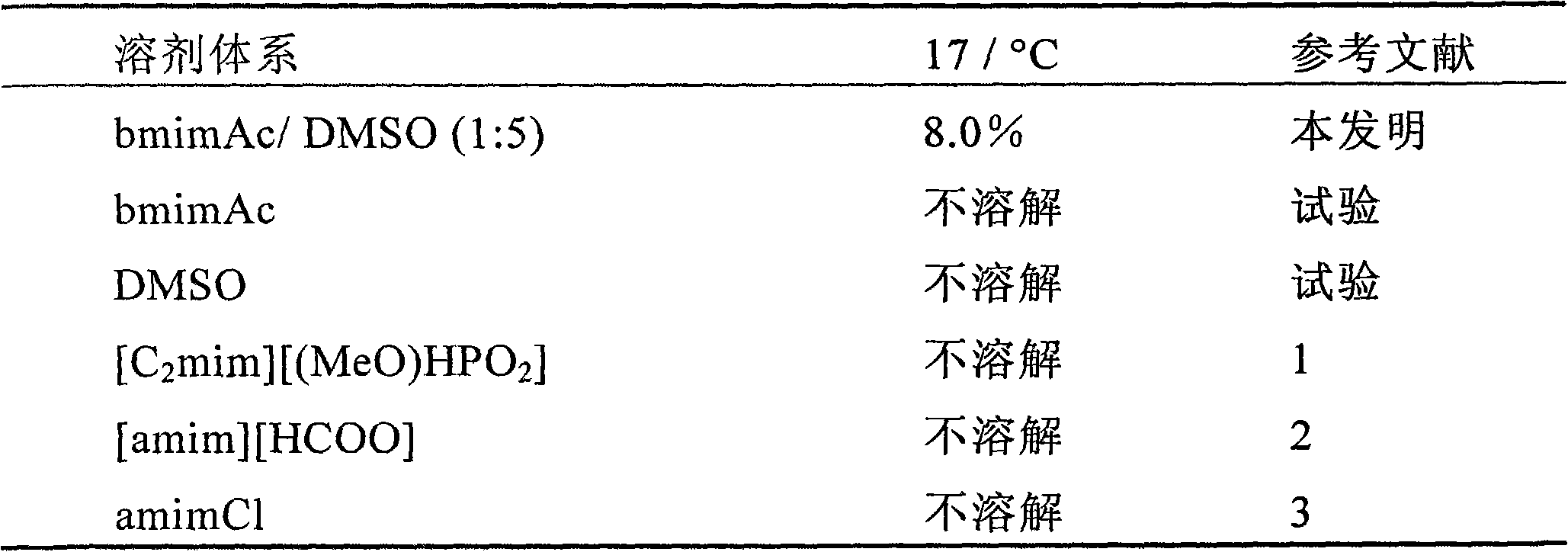

[0004] The present invention first screens out the ionic liquid 1-butyl-3-methylimidazolium acetate (bmimAc) which has a strong dissolving ability to cellulose, and then screens out the co-solvent dimethyl sulfoxide which can be miscible with (bmimAc) (DMSO), and then bmimAc and DMSO are dissolved in a certain proportion to form a composite solvent. After a large number of tests, the composite solvent made by bmimAc and DMSO with a mass ratio of 2:1-1:5 has excellent fiber-dissolving properties. The performance of cellulose has achieved the effect of dissolving cellulose in large doses at room temperature.

[0005] The present invention has following embodiment:

[0006] 1). A large dose of cellulose is dissolved at room temperature, which is obviously better than other solvents under the same conditions. For example: at 25°C, the solubility of microcrystalline cellulose in bmimAc / DMSO (1:1) can reach 15.0%; at 17°C, the solubility of microcrystalline cellulose in bmimAc / DMSO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com