Supercritical carbon dioxide ionic liquid degumming method for apocynum venetum bast fibers

A technology of carbon dioxide and ionic liquids, which is applied in the direction of producing bast fiber by chemical method, can solve the problems of hard to find, easy to pollute the environment, and large cellulose damage, and achieve the effect of fast degumming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

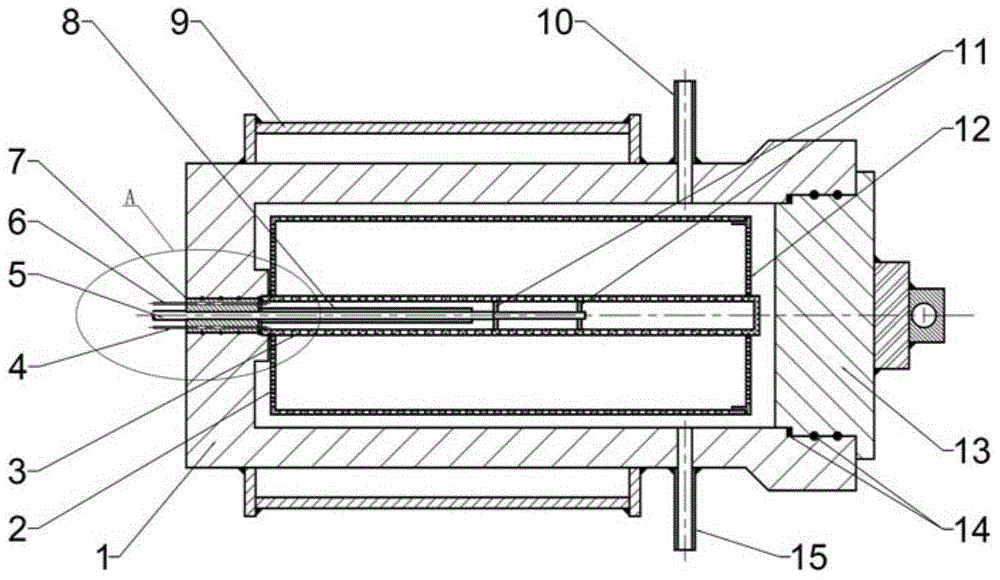

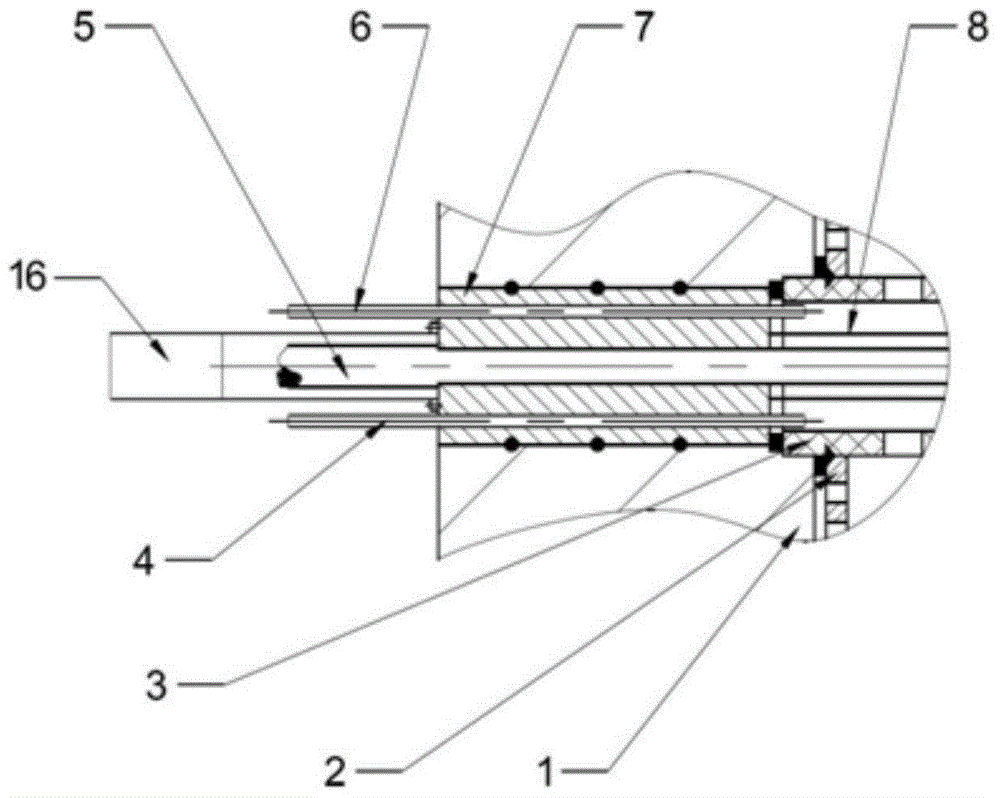

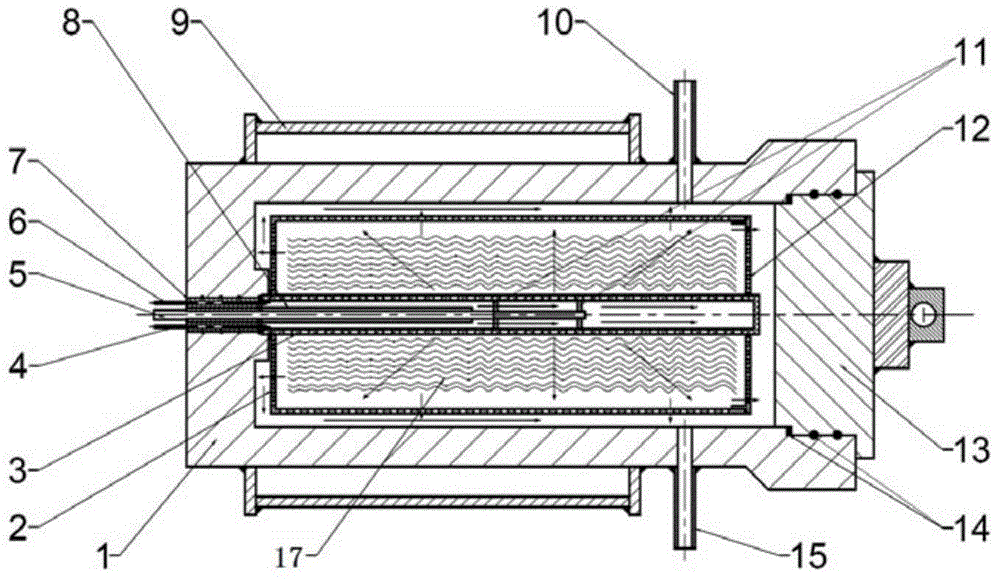

[0036] Such as image 3 As shown, 2kg apocynum bast fiber is placed in the cage 2, the cage cover 12 is covered, and put into the reactor cylinder 1, the central column 3 of the cage is hollow, and a threaded sleeve 11 and a motor are arranged inside. The threaded connection on the transmission shaft 5 is covered with a shoulder flat cover 13, and the reactor shell 1 is heated by the jacket 9, and carbon dioxide enters the cage center column 3 from the carbon dioxide inlet 4, and the ionic liquid degumming agent (ion Liquid and ethanol mass ratio is the degumming liquid of 5:1) enters in the cage center column 3 by reactant solution inlet 6 at the speed of 0.2kg / min, because the permeation hole that the cage center column evenly arranges, supercritical carbon dioxide and The reactant solution penetrates into the apocynum fiber inside by the permeable hole, and begins to degumming, due to the rotation of the motor drive shaft 5, the cage 2 rotates thereupon, (the effect of the ...

Embodiment 2

[0038] Put 4kg of apocynum bast fiber into the cage 2, cover the cage cover 12, put it into the reactor cylinder 1, the central column 3 of the cage is hollow, and has a threaded sleeve 11 and a motor drive shaft 5 inside The threaded connection on the upper cover is covered with a shoulder flat cover 13, and the reactor cylinder 1 is heated by the jacket 9, and carbon dioxide enters the cage center column 3 from the carbon dioxide inlet 4, and the ionic liquid degumming agent (ionic liquid and ethanol The degumming solution with a mass ratio of 2:1) enters the central column 3 of the cage from the reactant solution inlet 6 at a speed of 0.3kg / min. Due to the uniformly arranged permeation holes in the central column of the cage, supercritical carbon dioxide and the reactant solution Infiltrate into the inside of the apocynum fiber by the permeable hole, start to degumming, due to the rotation of the motor transmission shaft 5, the cage 2 rotates thereupon, (the effect of the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com