Multi-source spacing measurement device and method for neutron porosity during drilling

A neutron porosity and measuring device technology, applied in the field of petroleum drilling engineering, can solve the problem that the sensitivity of the probe and the accuracy of the data cannot be satisfied at the same time, and achieve the effect of real-time evaluation of the formation and guarantee of the accuracy of the data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

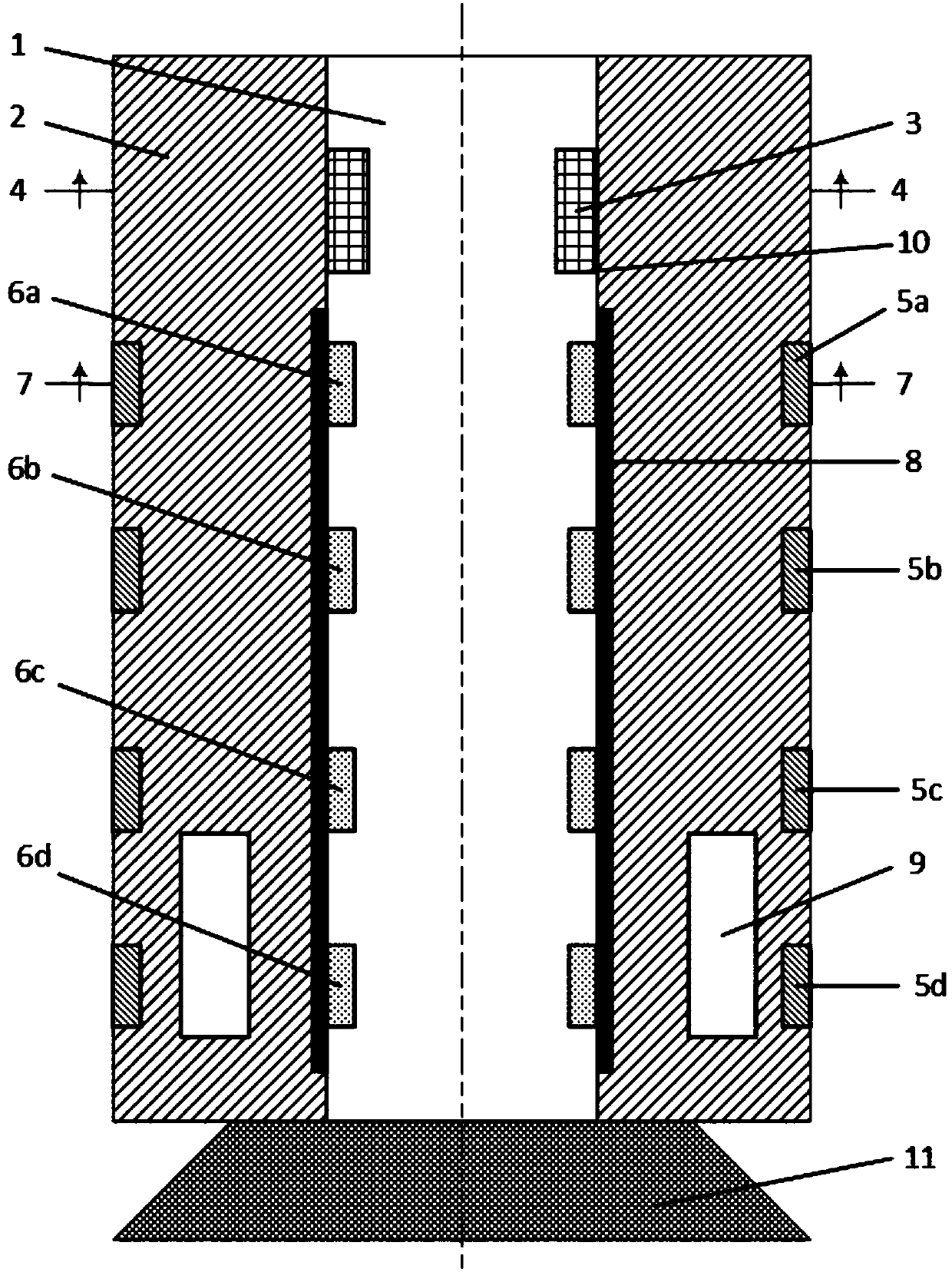

[0042] see Figure 1 to Figure 5 , shows the multi-source distance while drilling neutron porosity measuring device and its measuring method of the present invention.

[0043] Wherein said multi-source distance while drilling neutron porosity measurement device can include non-magnetic drill collar 2, neutron emission unit, fast neutron monitoring unit, thermal neutron detection unit and control unit, through the combination of these units, this The applied multi-source distance while drilling neutron porosity measurement device can convert the detection data into neutron porosity results according to different working conditions through a preset program downhole.

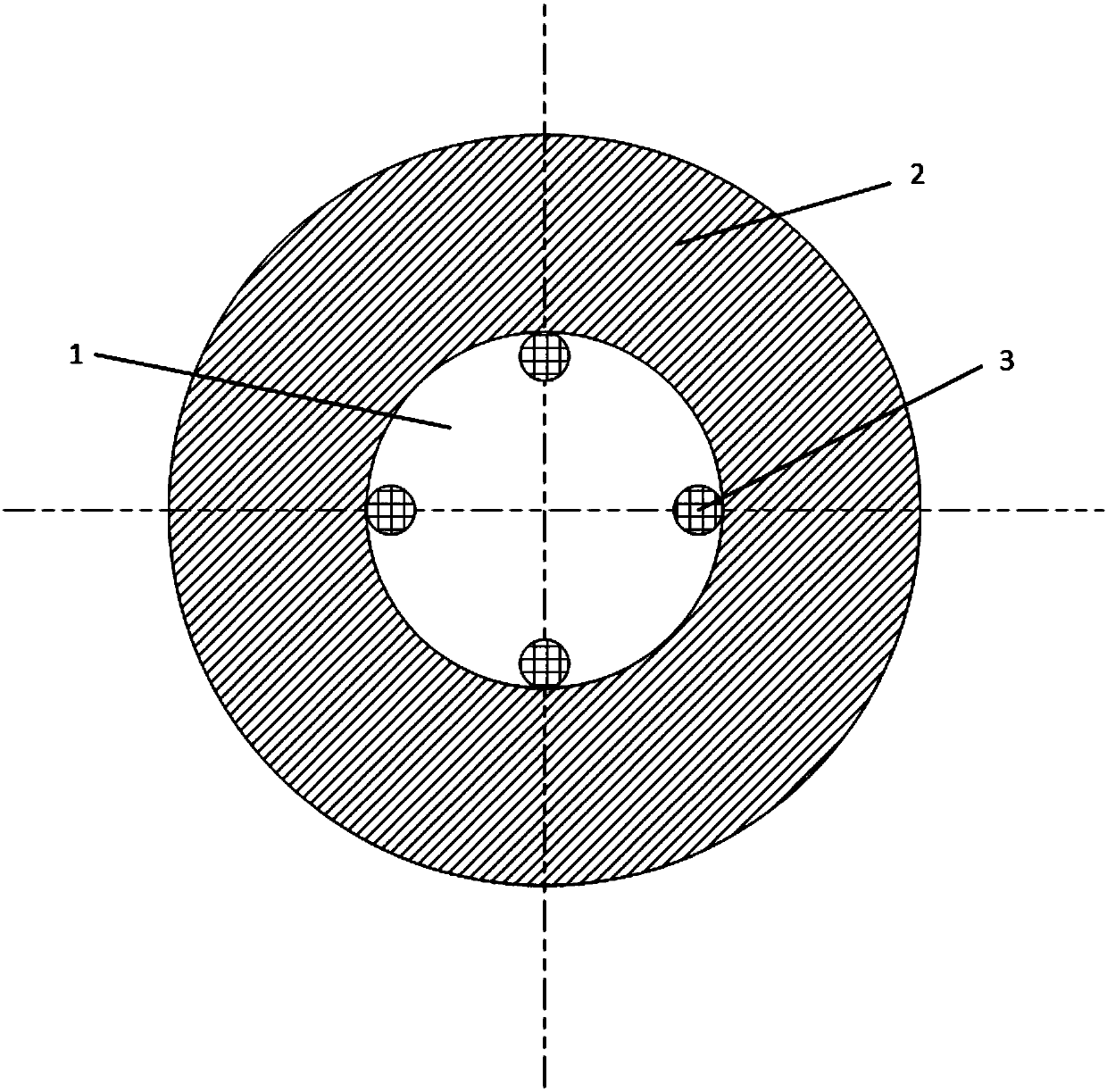

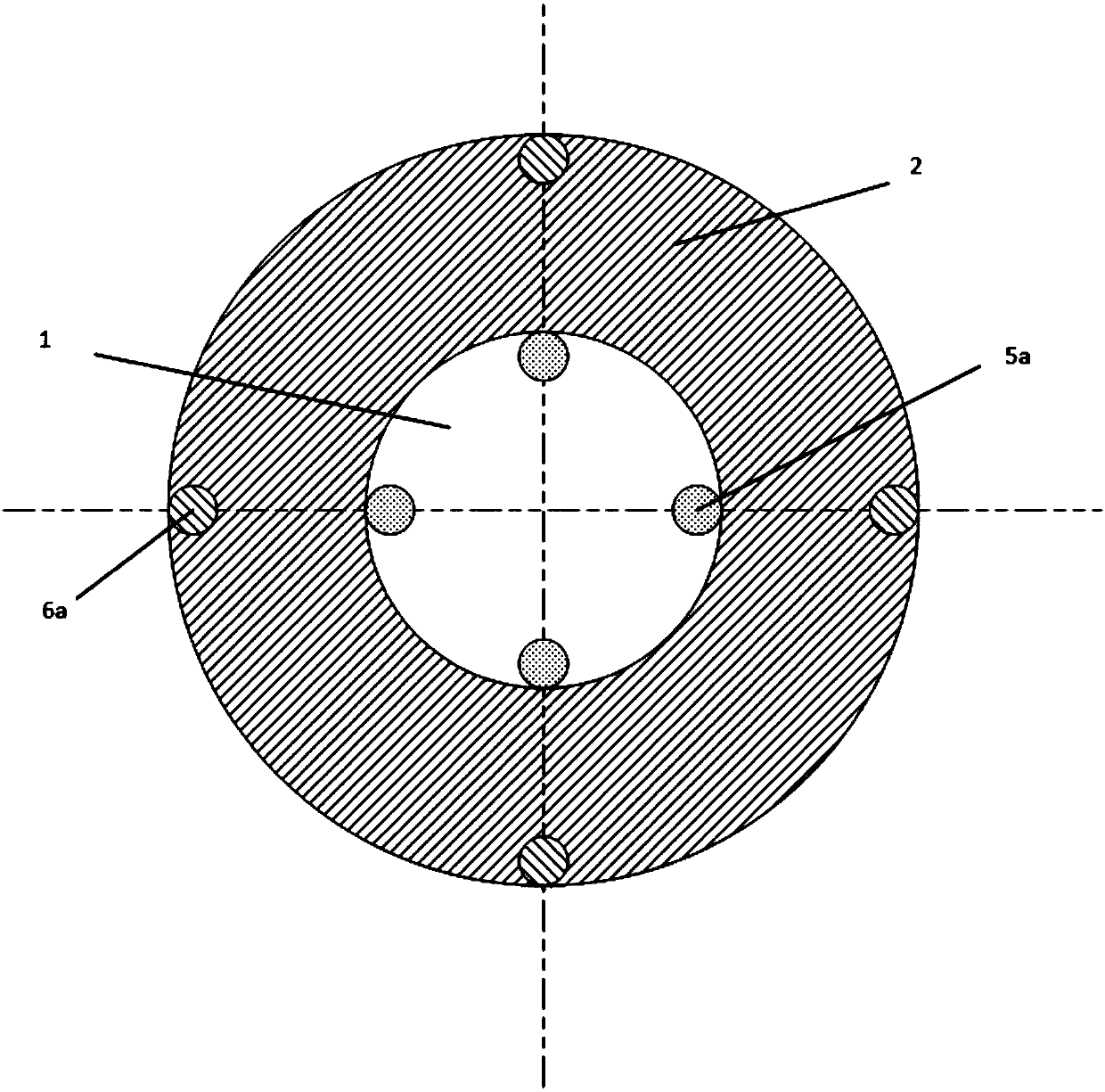

[0044] Wherein, the neutron emission unit may include a plurality of accelerator neutron sources 3, and a plurality of accelerator neutron sources 3 are arranged on the inner wall of the mud channel 1 at the same height along a certain angle interval, and the plurality of accelerator neutron sources 3 are all With...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com