Three-dimensional laser scanning device applied to plant potting and scanning method thereof

A 3D laser and scanning device technology, applied in the field of 3D scanning, can solve the problems of many sharp points, prone to bad spots, and low scanning accuracy, and achieve good scanning effect, safe and reliable use, and large scanning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

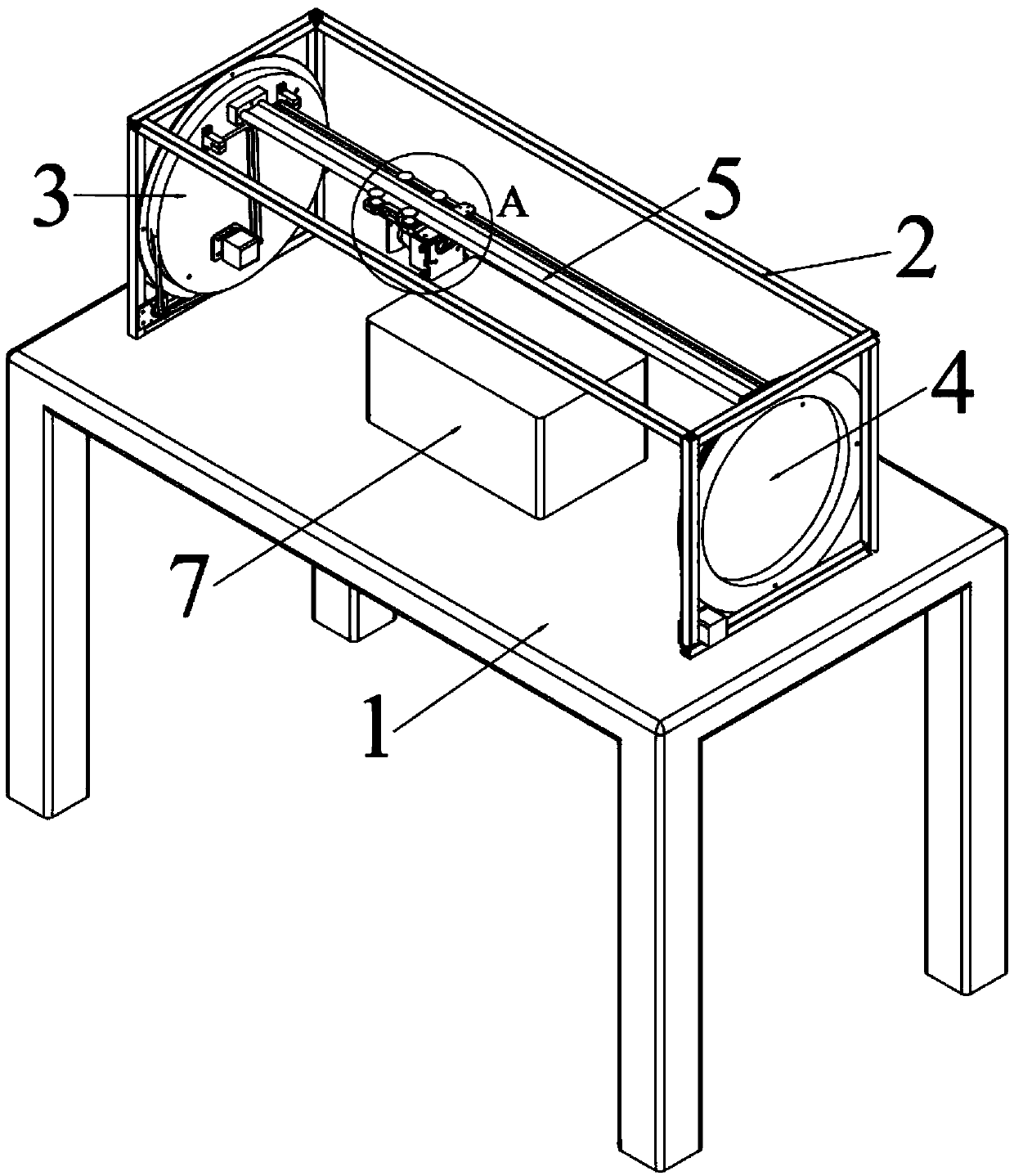

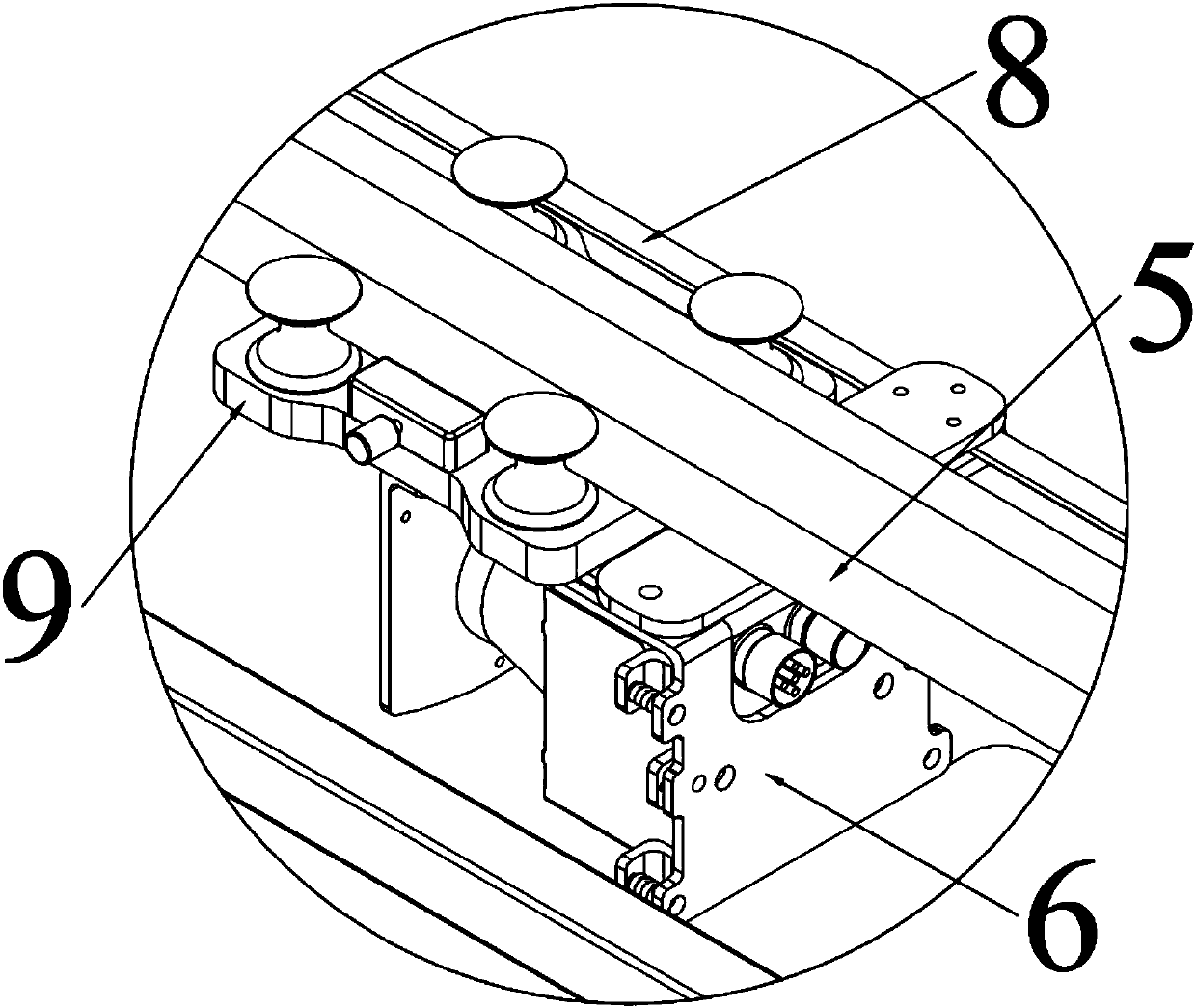

[0039] Such as figure 1 with 2 As shown, a three-dimensional laser scanning device applied to potted plants includes a workbench 1, a frame 2, a first turntable 3, a second turntable 4, a slide rail 5, a slider 9, a first synchronous pulley, a first Synchronous belt 8, second synchronous pulley, second synchronous belt, laser sensor 6, scanning table 7, first motor, second motor and third motor. The model of the laser sensor 6 is TIM510. The frame 2 is fixed on the workbench 1. The first turntable 3 and the second turntable 4 are respectively supported on two ends of the frame 2 . The axis lines of the first turntable 3 and the second turntable 4 are collinear and arranged horizontally. The first turntable 3 is driven by a first motor. The second turntable 4 is driven by a third motor. One end of the slide rail 5 arranged between the first turntable 3 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com