Heavy numerical control planing machine mobile workbench reliability test device

A technology of moving worktable and planer, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problem of inability to load the mobile worktable of heavy-duty CNC planer, and shorten the data collection time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below in conjunction with accompanying drawing:

[0045] It should be clear that the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative work fall within the protection scope of the present invention:

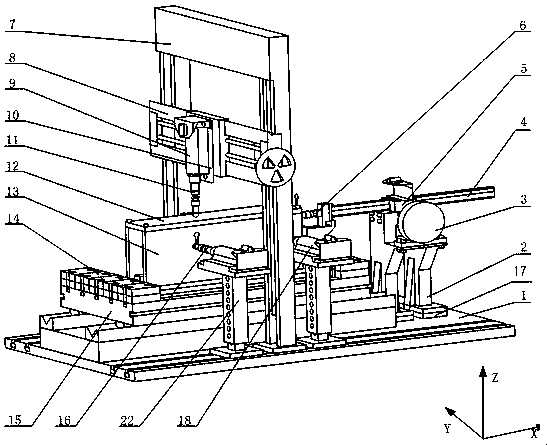

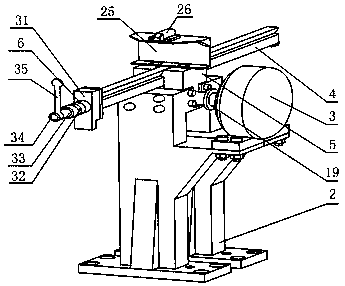

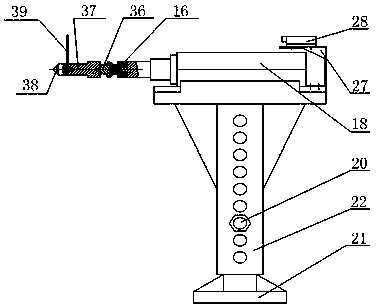

[0046] refer to figure 1 , the heavy-duty numerical control gantry planer mobile workbench reliability test device of the present invention includes a counterweight inertial loading part, a loading auxiliary part, an X-direction loading part, a Y-direction loading part, a Z-direction loading part and an automatic control part.

[0047] According to the actual working conditions of the heavy-duty CNC gantry planer, the present invention proposes a method that uses a magnetic powder brake and a hydraulic servo loading device to simulate static pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com