Epitaxial structure capable of lowering switch-on resistance of super-junction device and manufacturing method

An epitaxial structure and on-resistance technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., to increase the impurity injection concentration, solve the problem of diffusion and recombination, and improve the on-resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

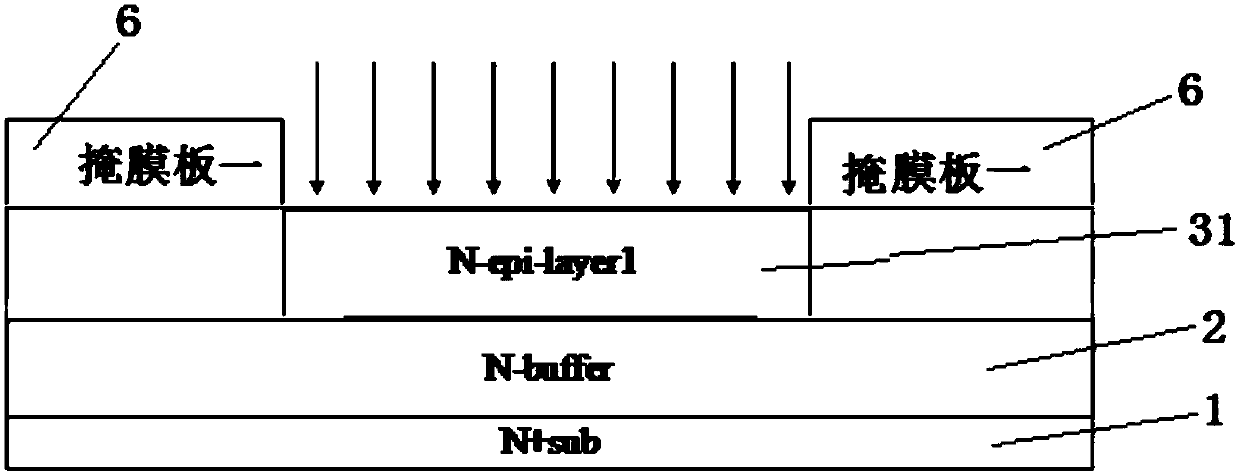

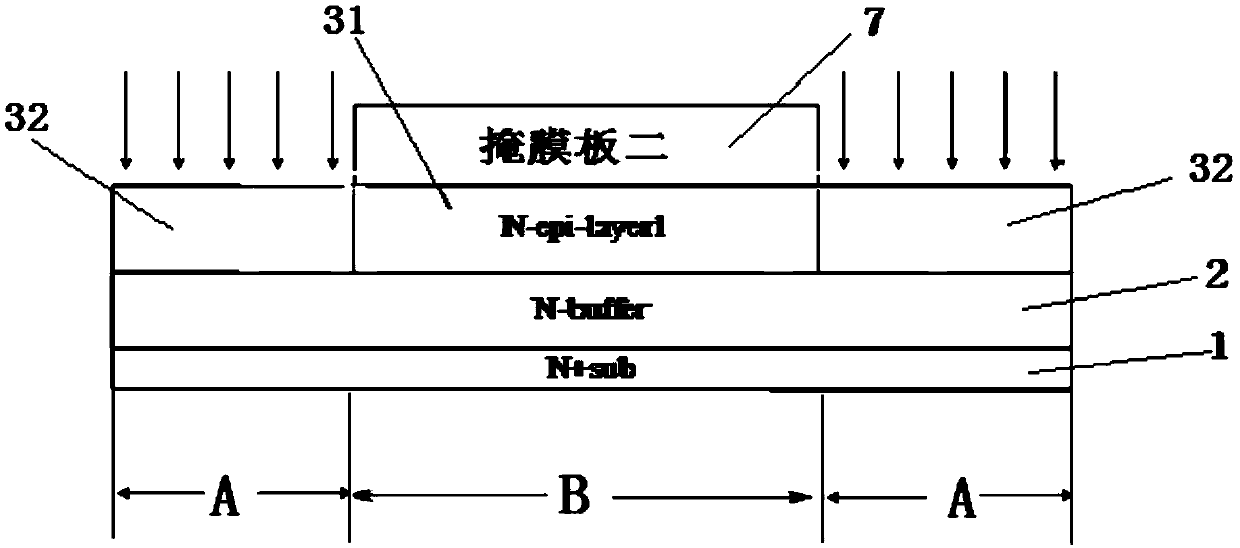

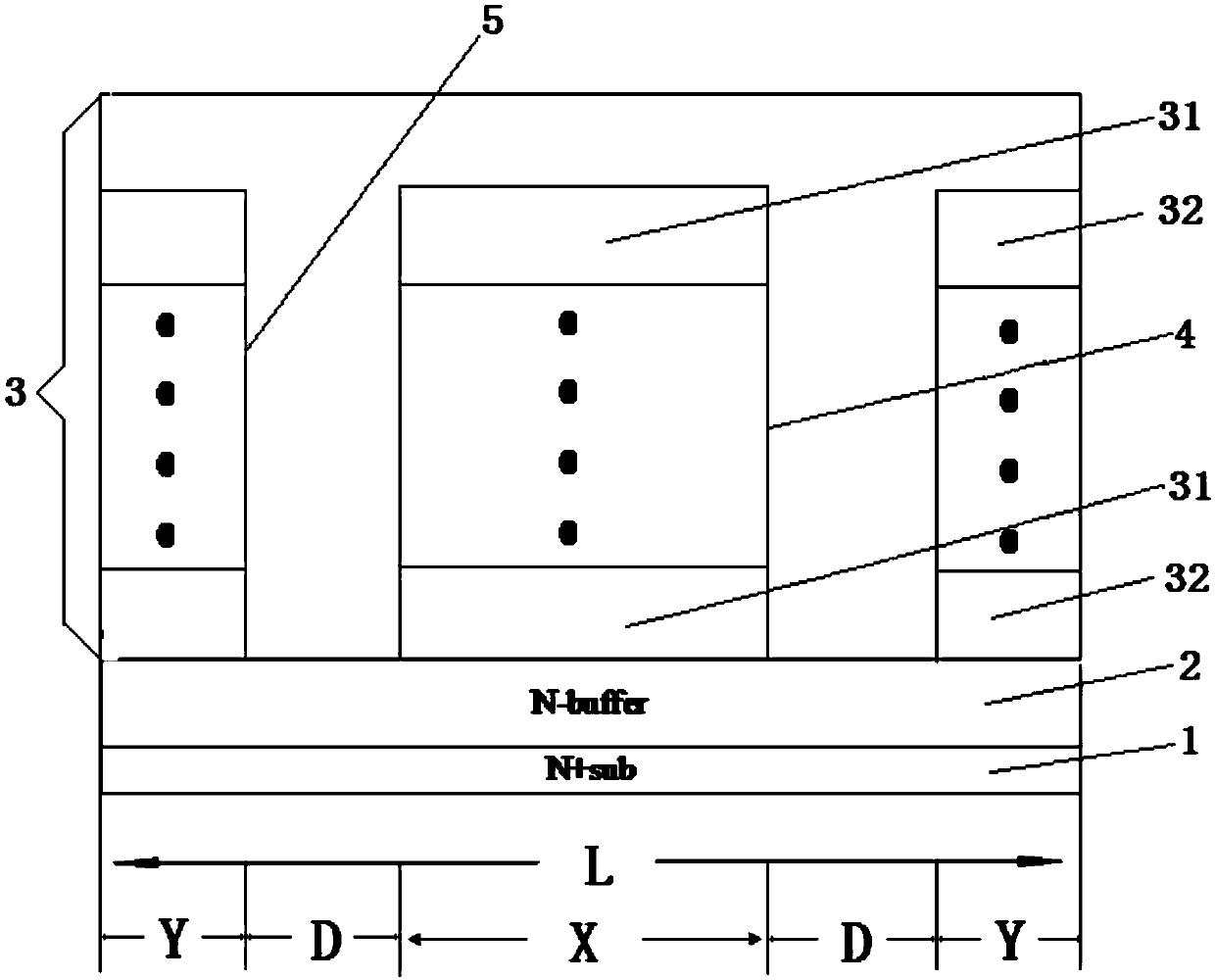

[0032] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0033] According to attached image 3 As mentioned above, the epitaxial structure of the super-junction device in the embodiment of the present invention takes N-type conduction as an example, the first conduction type is N-type conduction, and the second conduction type is P-type conduction. The epitaxial structure of the on-resistance includes a cell area, and the cell area includes several device unit bodies, and the device unit body includes an N-type heavily doped substrate 1 located on the N-type heavily doped substrate 1 The N-type buffer layer 2 on the upper N-type buffer layer 2 and the N-type epitaxial layer 3 on the N-type buffer layer 2 are characterized in that there are several An N-type implanted region 31 and several P-type implanted regions 32, the several N-type implanted regions 31 are connected to form an N-type column 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com