Plug assembly with male and female integration, plug combination assembly structure and connector with the same

A technology of plug assembly and combined structure, which is applied in the direction of two-part connection device, connection, parts of connection device, etc., can solve problems such as bite corrosion, reduce plug life, waste, etc., and achieve fast and convenient insertion and extraction, plug-in The effect of increasing the number of pulls and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

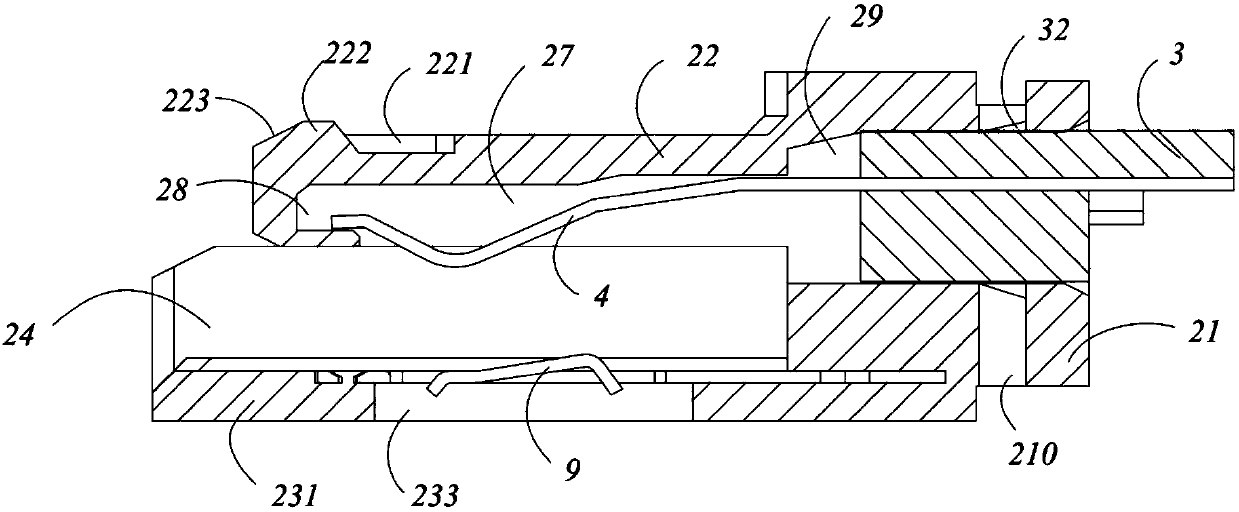

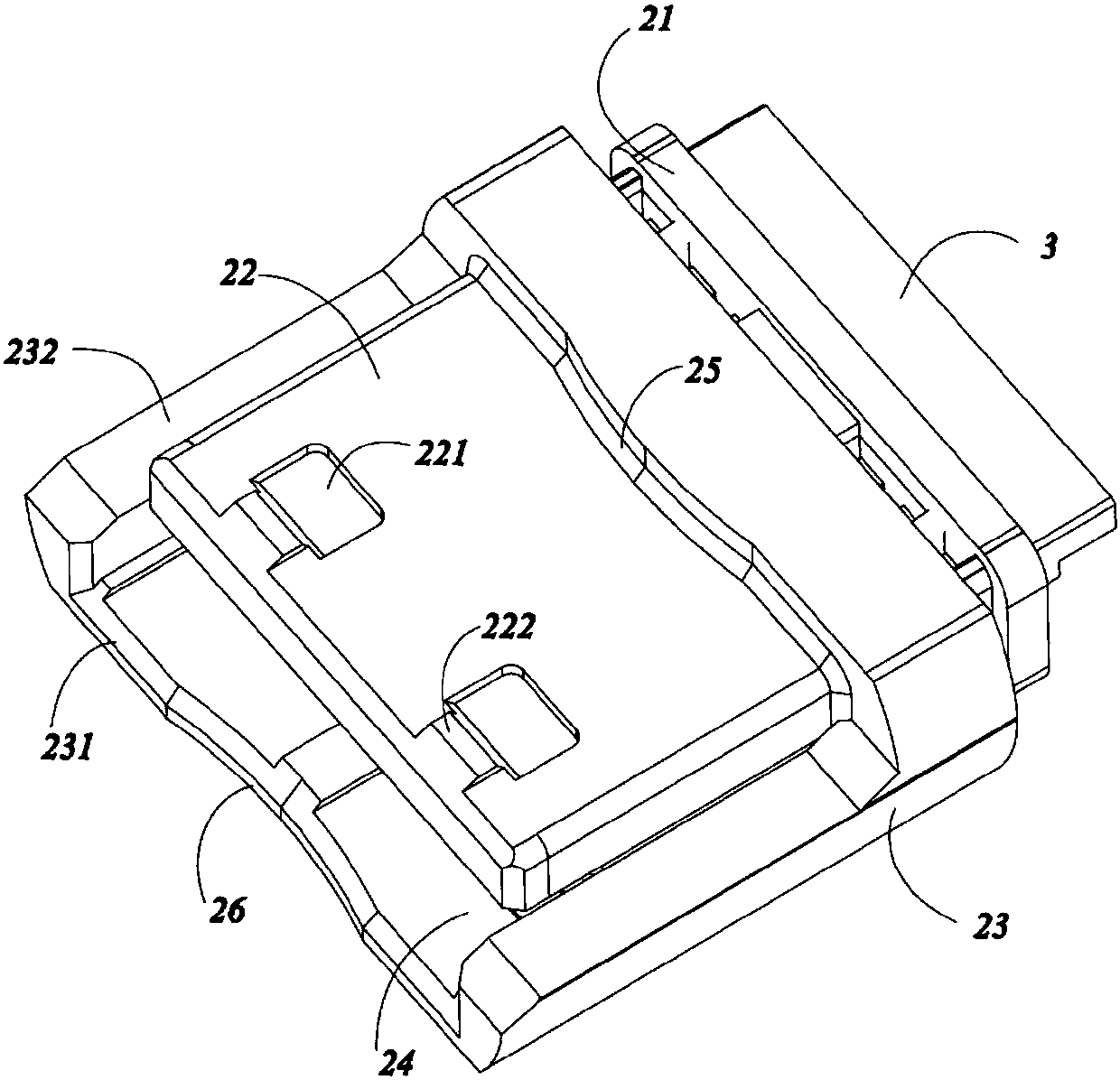

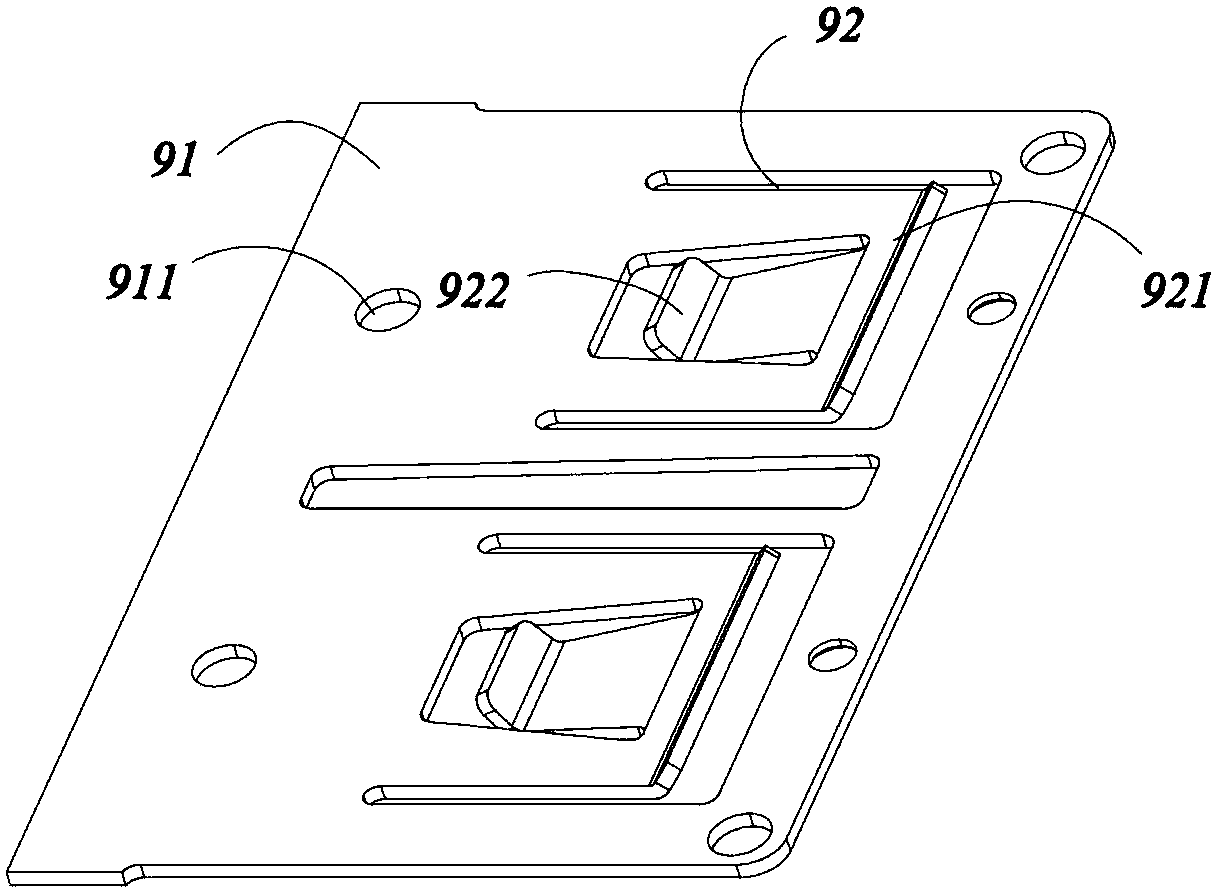

[0034] Such as figure 1 and figure 2 A male-female plug assembly is shown, including a separate plug 2, a terminal positioning block 3 located on the plug 2, and a metal sheet 4 for conducting electricity inserted into the plug 2 through the terminal positioning block 3. The plug 2 includes a base 21, a guide 22 protruding upward from the base 21, and a positioning member 23, and an insertion cavity 24 is formed between the guide 22 and the positioning member 23; the positioning member 23 includes a base plate 231 and a The side plates 232 extending upward on both sides, the insertion cavity 24 is formed between the two side plates 232, the bottom plate 231 and the guide 22; The spring leaf 9 is provided with a positioning groove 221 on the side away from the insertion cavity 24 on the guide member 22; The positioning groove 221 of the plug 2 is matched; the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com