Belt carrier fixing plate

A technology of fixing plates and loops, applied in the directions of ligaments, muscles, etc., can solve the problems of unadjustable length, increase operation time, etc., and achieve the effect of increasing service life, expanding application scope, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

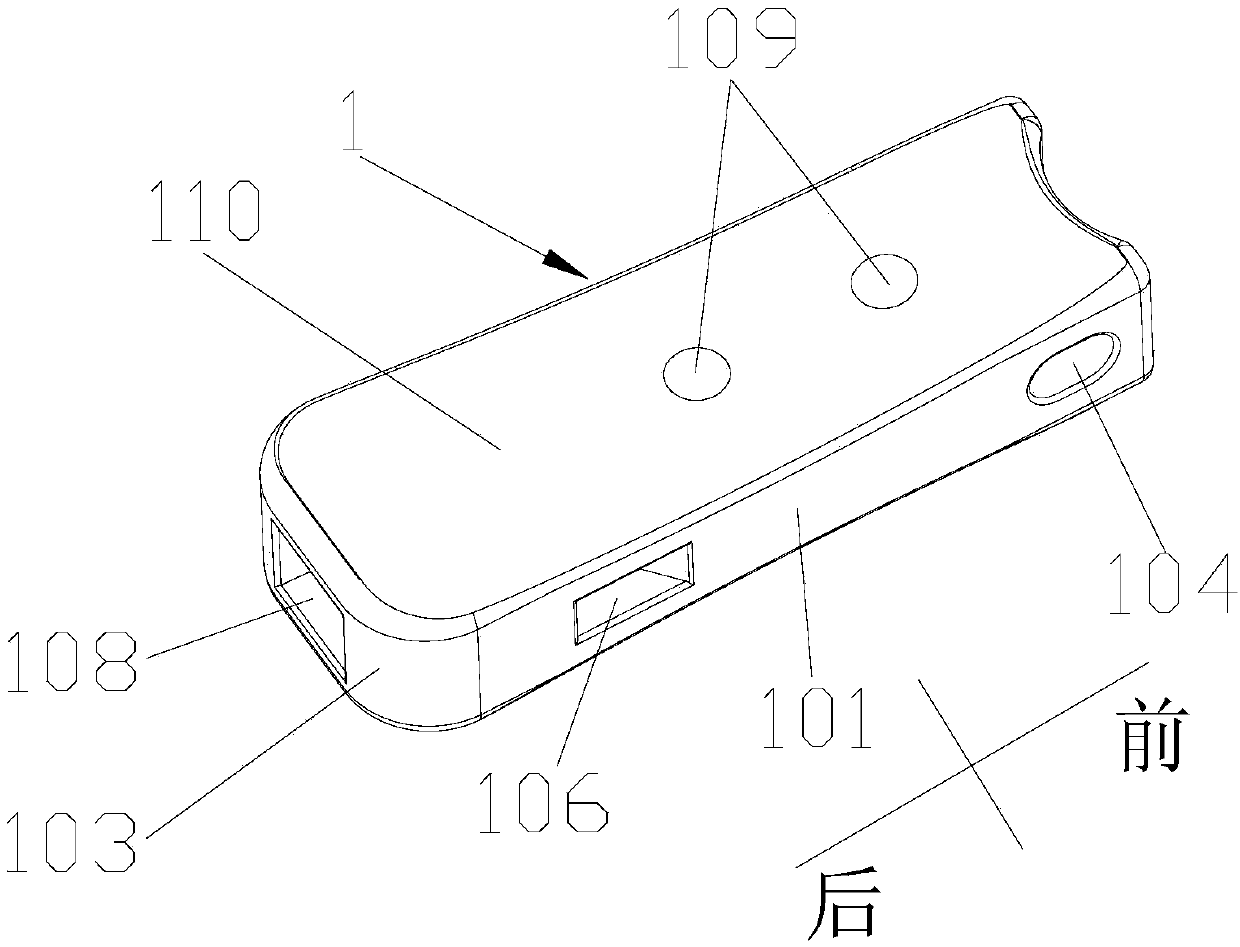

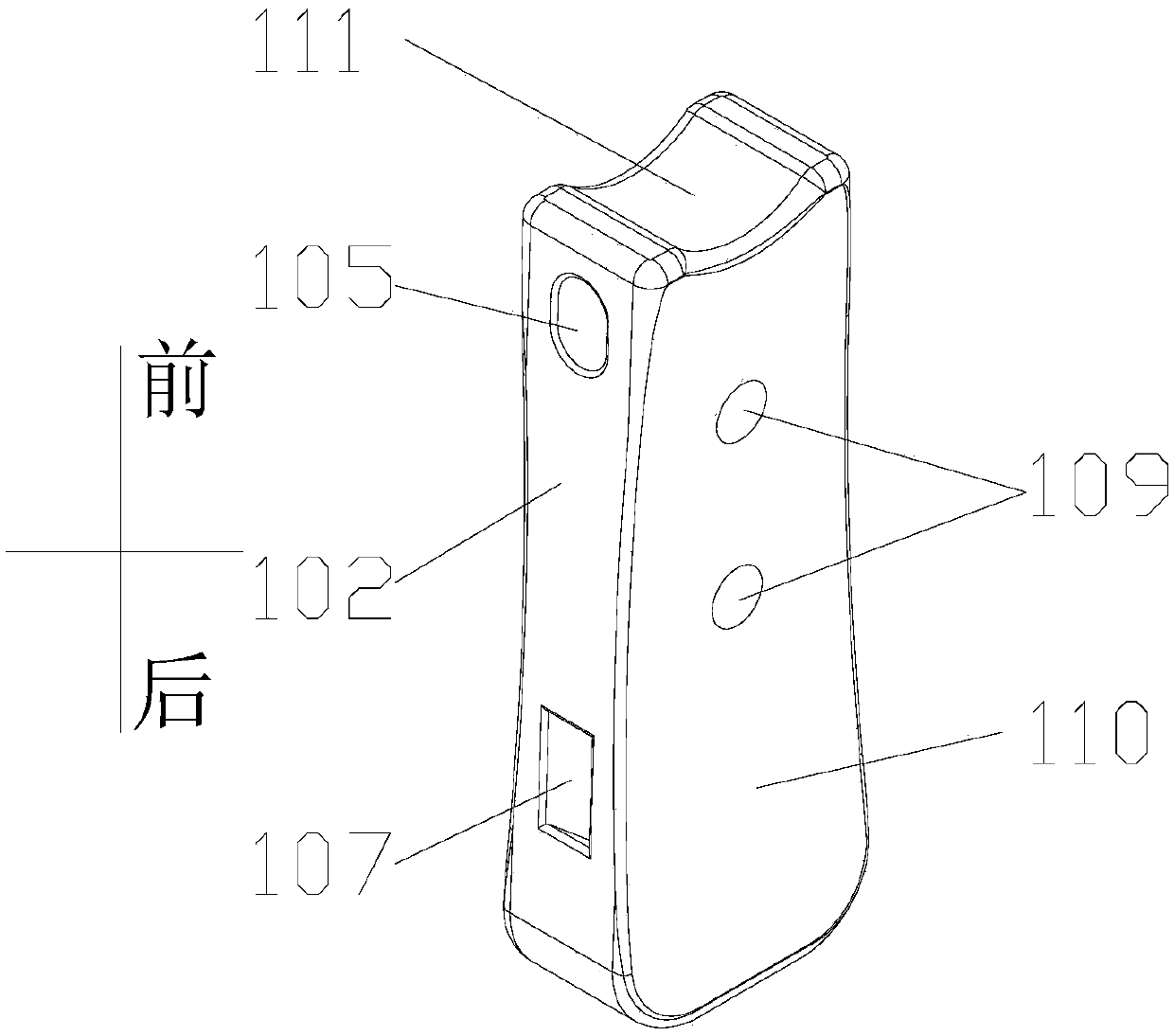

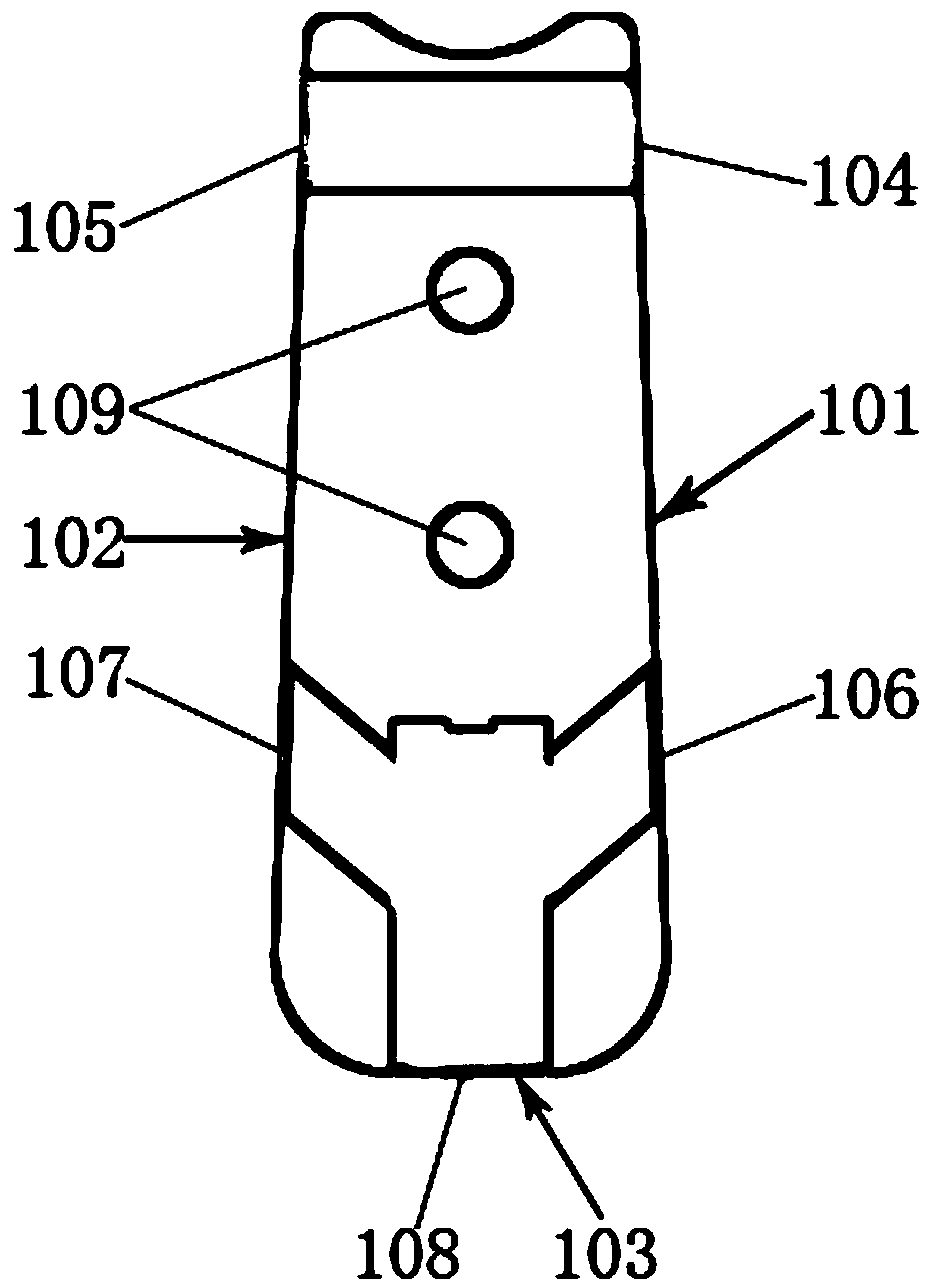

[0023] Embodiment 1 of the present invention: as Figure 1-Figure 5 As shown, a belt loop fixing plate includes a first fixing plate 1 , a second fixing plate 2 and a connecting line 3 , and the first fixing plate 1 and the second fixing plate 2 are connected through the connecting line 3 . Wherein the first side 101 and the second side 102 of the first fixing plate 1 are symmetrically arranged, the front end of the first side 101 is provided with a side hole A1, and the front end of the second side 102 is provided with a side hole A2, so The side hole A1 and the side hole A2 are arranged symmetrically and communicate with each other. A side hole B1 is defined at the rear end of the first side 101 , and a side hole B2 is defined at the rear end of the second side 102 . The side holes B1 and B2 are arranged symmetrically and communicate with each other. The rear end face 103 of the first fixing plate 1 is provided with a rear end face hole 108, the rear end face hole 108 commu...

Embodiment 2

[0025] Embodiment 2: as Figure 1-Figure 5 As shown, a belt loop fixing plate includes a first fixing plate 1 , a second fixing plate 2 and a connecting line 3 , and the first fixing plate 1 and the second fixing plate 2 are connected through the connecting line 3 . Wherein the first side 101 and the second side 102 of the first fixing plate 1 are symmetrically arranged, the front end of the first side 101 is provided with a side hole A1, and the front end of the second side 102 is provided with a side hole A2, so The side hole A1 and the side hole A2 are arranged symmetrically and communicate with each other. A side hole B1 is defined at the rear end of the first side 101 , and a side hole B2 is defined at the rear end of the second side 102 . The side holes B1 and B2 are arranged symmetrically and communicate with each other. The rear end face 103 of the first fixing plate 1 is provided with a rear end face hole 108, the rear end face hole 108 communicates with the side hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com