Fertilizer crushing machining device

A processing device and fertilizer technology, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of unfavorable mechanical fertilization, poor crushing effect, and blockage of fertilization nozzles, so as to improve the working efficiency of sieving materials and improve the uniformity of crushing The effect of improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

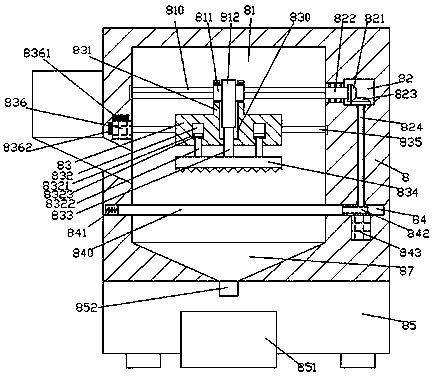

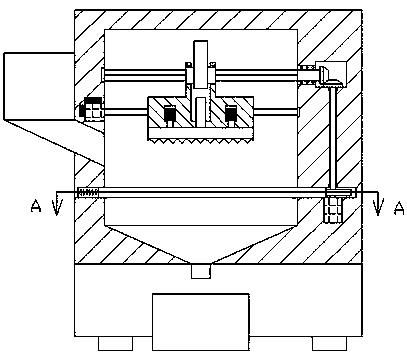

[0019] Such as Figure 1-Figure 4 As shown, a fertilizer crushing and processing device of the present invention includes a processing machine body 8, a first cavity 81 is arranged inside the processing machine body 8, and a funnel extending downwards is connected to the bottom of the first cavity 81. Cavity 87, the first cavity 81 is provided with a mobile bracket 83 that is connected with the front and rear end faces and the front and rear inner walls of the first cavity 81 in a pressure-sliding fit, and the mobile bracket 83 is provided with a screw fit connection and left and right Extended threaded rod 835, grooves 830 are provided in the top end surface of the mobile bracket 83, and support frames 831 extending upwards are fixed at the edges of the left and right sides of the top of the groove 830, and the supports on the left and right sides An inner spline sleeve 811 is rotationally fitted and connected between the frames 831, a first eccentric wheel 812 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com