Profile cutting machine

A cutting machine and profile technology, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of high cost, easily damaged equipment, and difficult to move, so as to save manpower and material resources, accurate length positioning, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

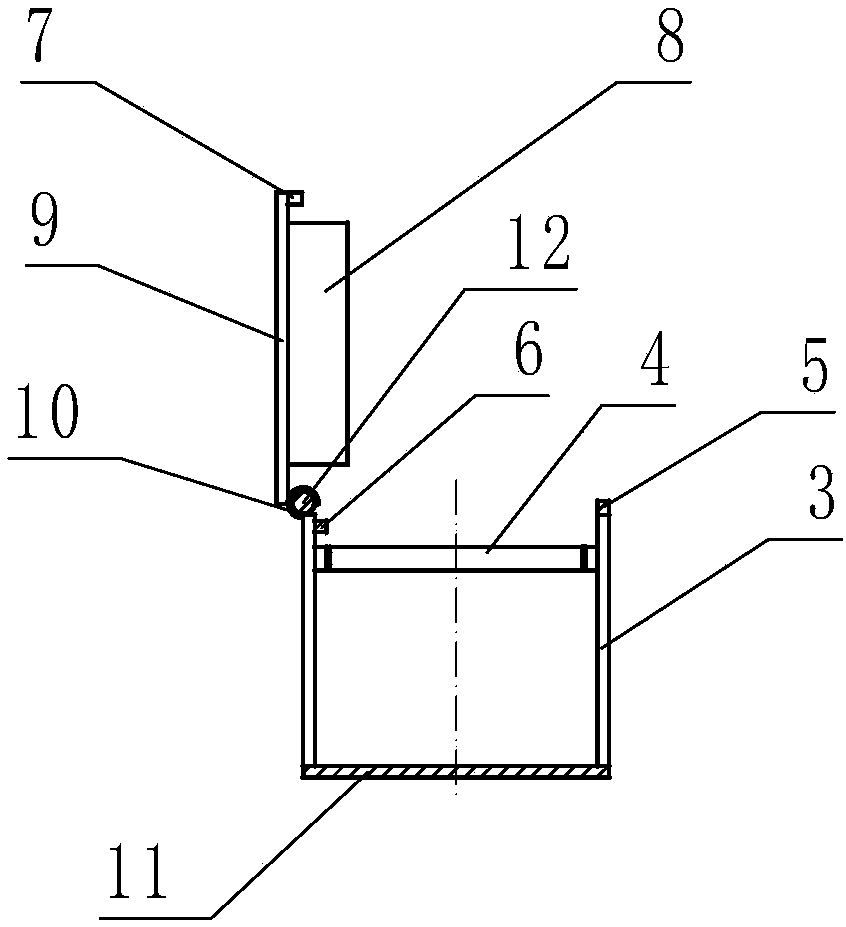

[0014] Embodiment 1: refer to figure 1 — image 3 , is a structural schematic diagram of Embodiment 1 of the present invention, comprising a frame 3, a base 11, a roller shaft 4, a clamp 1 and a cutting device 2, and vertically arranged frames 3 are arranged on both sides of the base 11, and on the frame 3 Horizontal roller shaft 4 is arranged between, and the top of frame 3 one side is provided with the slide rail 12 that cross section is circular, is provided with semicircular movable sleeve 10 on slide rail 12, on movable sleeve 10 Be provided with moving bar 9, be provided with moving lock 7 at the other end of moving bar 9, be provided with baffle plate 8 below moving bar 9, be provided with scale 6 on the frame 3 below slide rail 12, on the other side The top of the frame 3 is provided with a fixed lock 5, put down the moving rod 9, the locking between the moving lock 7 and the fixed lock 5 is realized, and the front end of the base 11 is provided with a clamp 1 for cla...

Embodiment 2

[0016] Embodiment 2: Compared with Embodiment 1, the difference of Embodiment 2 is that: the dynamic lock 7 is a magnetic body, and the fixed lock 5 is an object with attracting ferromagnetism, and the object with attracting ferromagnetism is Iron, cobalt, nickel and other metals or alloys of iron, cobalt, nickel and other metals.

Embodiment 3

[0017] Embodiment 3: Compared with Embodiment 2, the difference of Embodiment 3 is that the dynamic lock 7 is an object with attractive ferromagnetism, and the fixed lock 5 is an electromagnetic lock.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com