Double-layer nozzle and double-row pipe gas wave refrigerator with built-in drive hydraulic balance

A gas wave refrigerator, double-layer nozzle technology, applied in the direction of gas cycle refrigerators, refrigerators, compressors, etc., can solve problems such as shortening the life of the machine, improve the service life, reduce the impact of gas leakage, and simplify the supporting system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

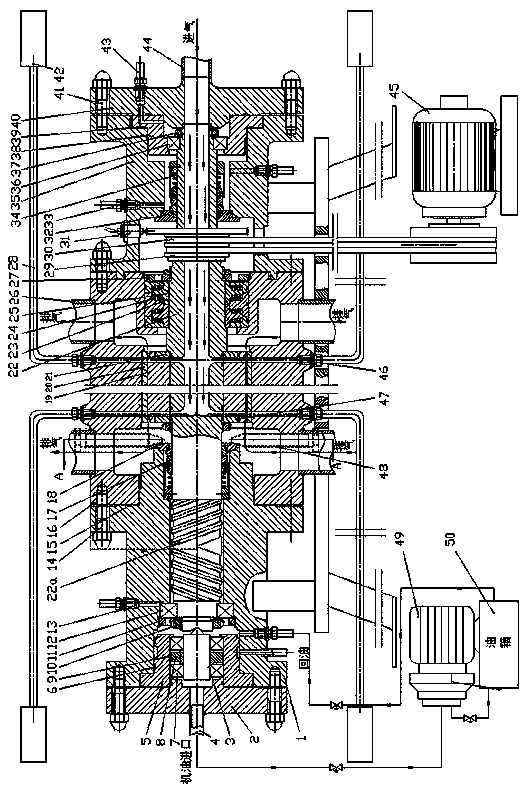

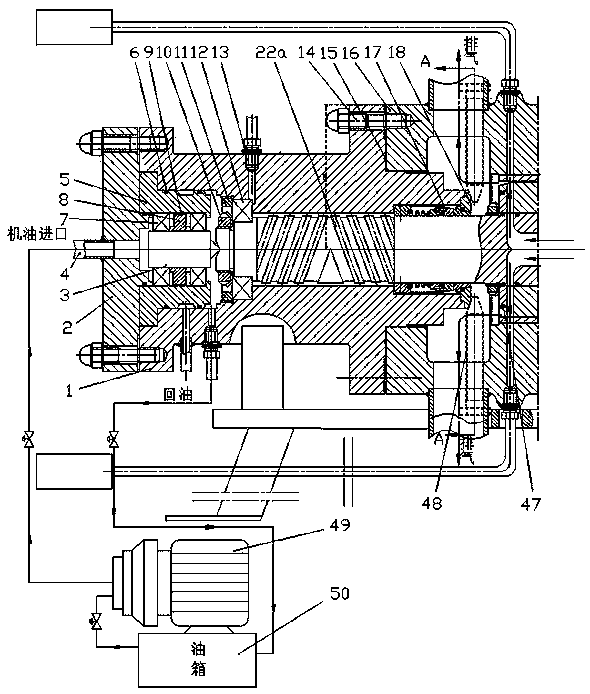

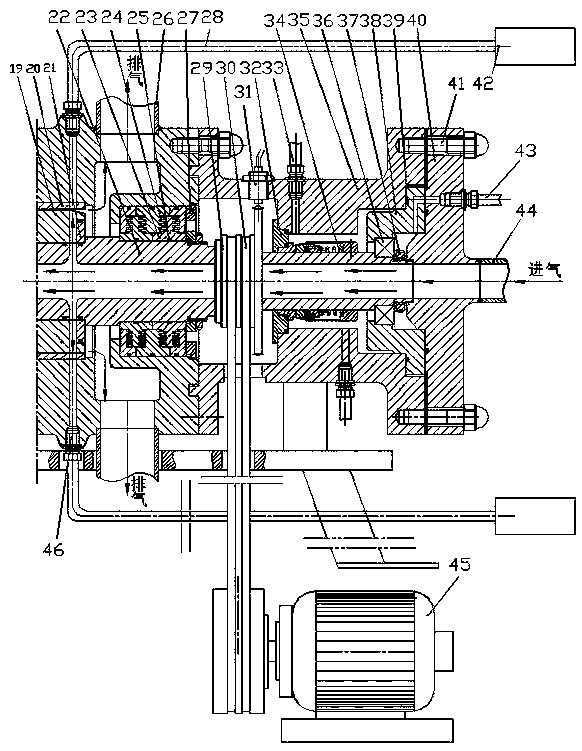

[0030] Figures 1, 2, 3, and 4 show the structure diagram of a double-layer nozzle double-row tube gas wave refrigerator with built-in driving hydraulic balance. In the figure, the machine consists of left body 1, left end cover 2, hydraulic mandrel 3, hydraulic oil inlet pipe 4, hydraulic cylinder block 5, main body 16, single-end mechanical seal I17, double-layer nozzle 19, bushing 20, nozzle Pressing plate 21, main shaft 22, vibration receiving tube 28, belt pulley 29, right body 35, embedded right bearing seat 38, right end cover 40 etc. are formed; The right body 35 constitutes, together with the left end cover 2 and the right end cover 40 constitute the whole shell of this machine. The main shaft 22 inside the body is a solid shaft on the left side and a hollow shaft on the right side. The main shaft 22 is equipped with a double-layer noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com