Electrophotographic Photoreceptor, Process Cartridge, And Image-Forming Apparatus

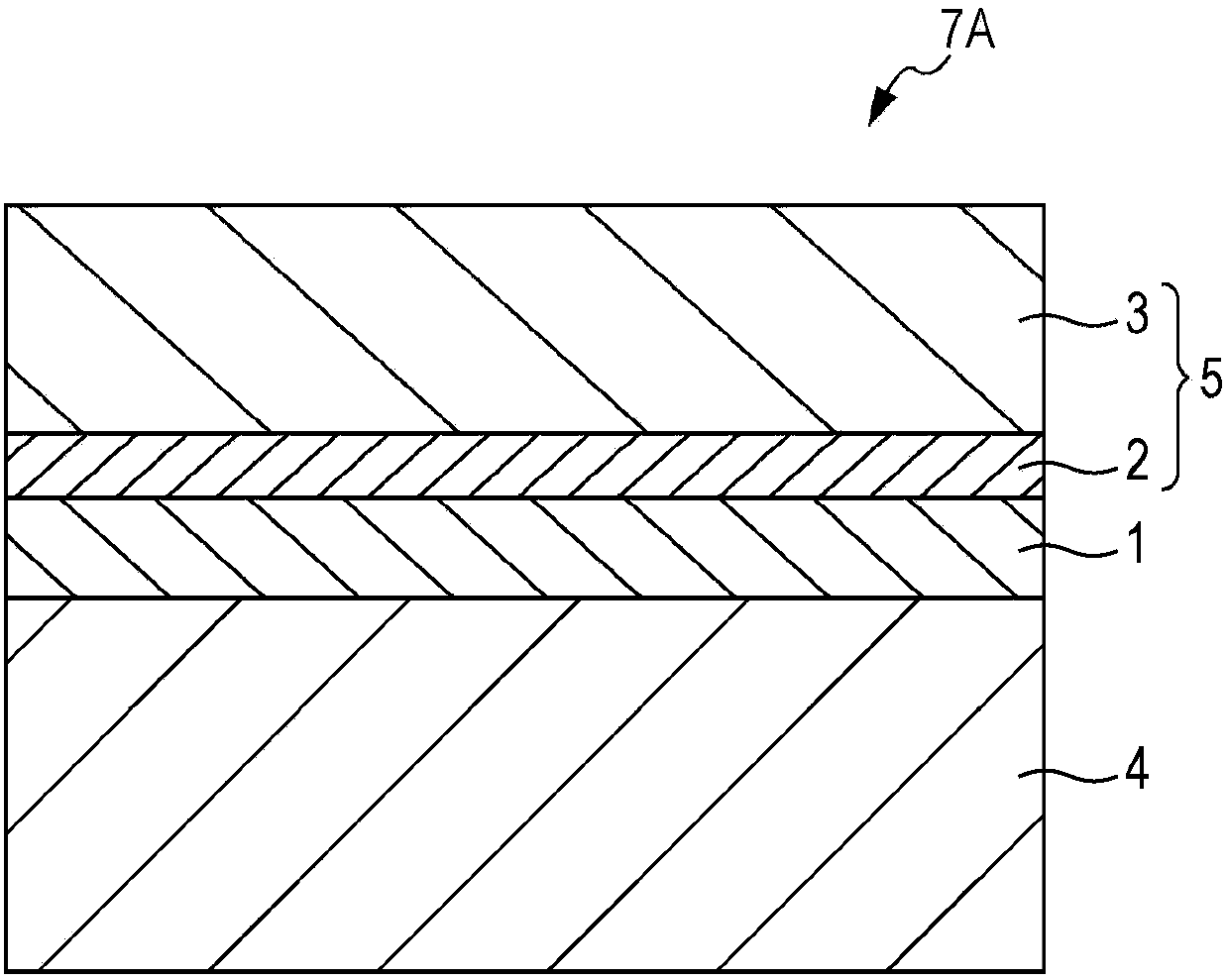

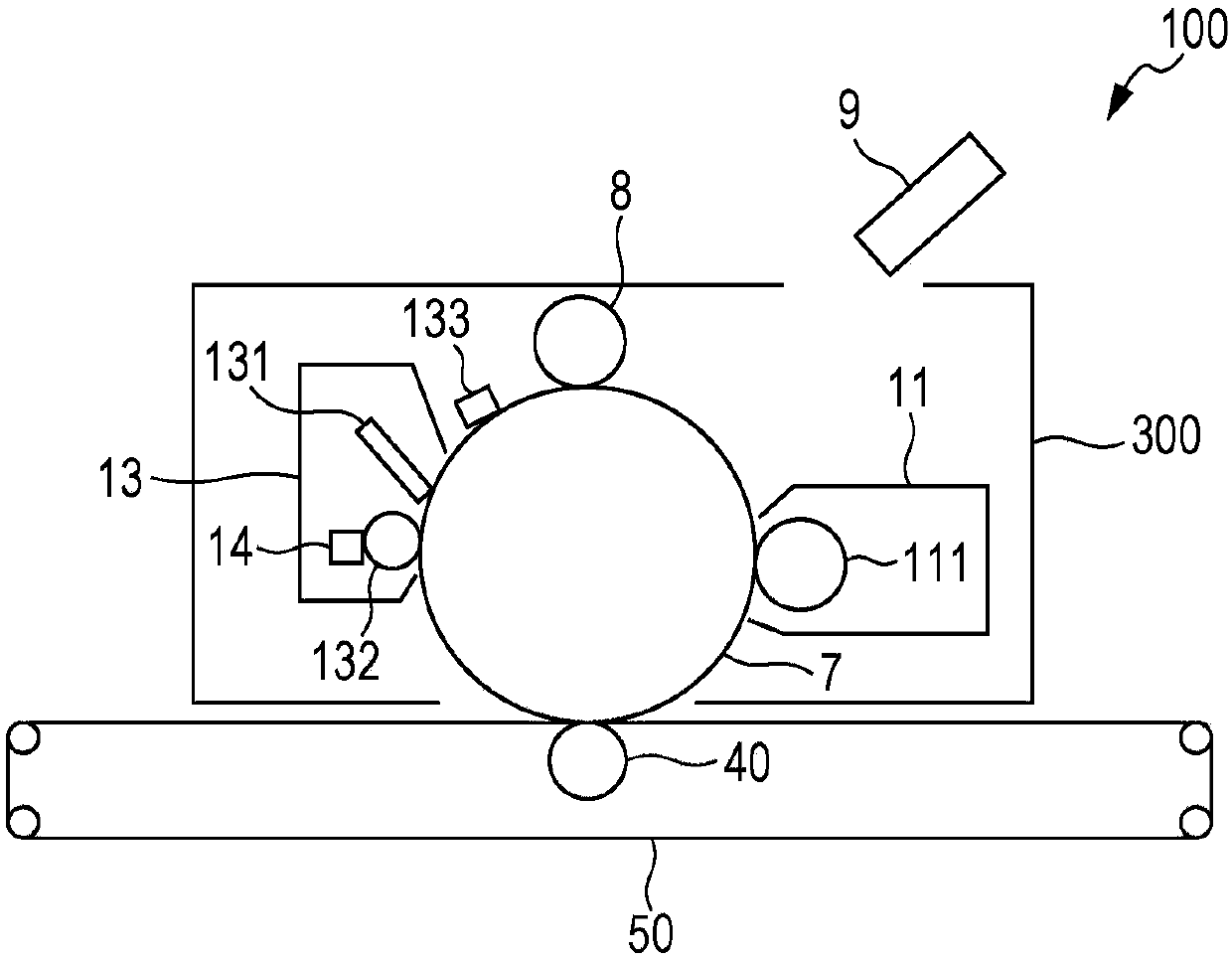

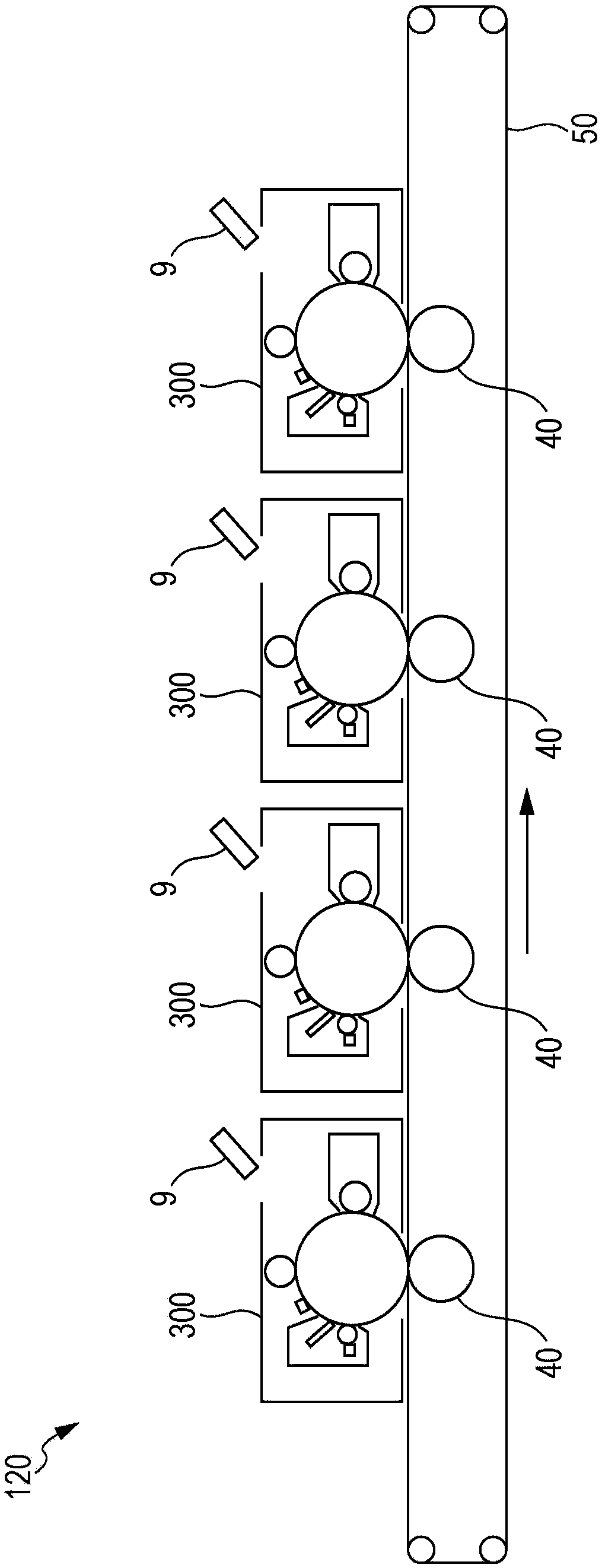

A technology for electrophotography and photoreceptors, which is applied in the field of process boxes, image forming devices, and electrophotographic photoreceptors, and can solve problems such as end wear of photosensitive layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0235] 100 parts by weight of zinc oxide (average particle diameter: 70 nm, specific surface area: 15 m 2 / g) was stirred and mixed with 500 parts by weight of methanol. To the resulting mixture was added 0.75 parts by weight of a silane coupling agent "KBM603" manufactured by Shin-Etsu Chemical Co., Ltd., and then the mixture was stirred for 2 hours. The mixture was then distilled under reduced pressure to remove methanol. Subsequently, it was baked at 120° C. for 3 hours. Thus, zinc oxide particles having surfaces treated with a silane coupling agent were prepared.

[0236] 85 parts by weight of methyl ethyl ketone, 60 parts by weight of surface-treated zinc oxide particles, 1.2 parts by weight of alizarin as a reactive acceptor substance, and a curing agent produced by Sumitomo Bayer Polyurethane Co., Ltd. (SumitomoBayer Urethane Co., Ltd.) 13.5 parts by weight of blocked isocyanate "Sumidur 3173" and 15 parts by weight of butyral resin manufactured by Sekisui Chemical C...

Embodiment 2 to 4 and comparative example 1 to 4

[0246] In Examples 2 to 4 and Comparative Examples 1 to 4, photoreceptors were prepared as in Example 1 except that the following charge transport layer formation conditions were changed as described in Table 1:

[0247] 1) Type of binder resin,

[0248] 2) the content of the solvent in the coating liquid for forming the charge transport layer, and

[0249] 3) Drying conditions in the formation of the charge transport layer, that is, specifically, the drying temperature of the portion of the coating film corresponding to the end A of the charge transport layer, that is, the photosensitive layer (in Table 1, referred to as "end A drying temperature"), the drying temperature of the part of the coating film corresponding to the other end B of the charge transport layer, that is, the photosensitive layer (in Table 1, referred to as "the drying temperature of the other end B"), and the That is, the drying temperature of the part of the coating film corresponding to the central par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com