Direct drive hub motor for electric vehicle

A hub motor and electric vehicle technology, applied in the field of electric vehicles, can solve the problems affecting the service life of permanent magnets of permanent magnet motors, the unreasonable strength of cooling system and motor rotor shaft, etc., and achieve easy heat dissipation, high motor power and small internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

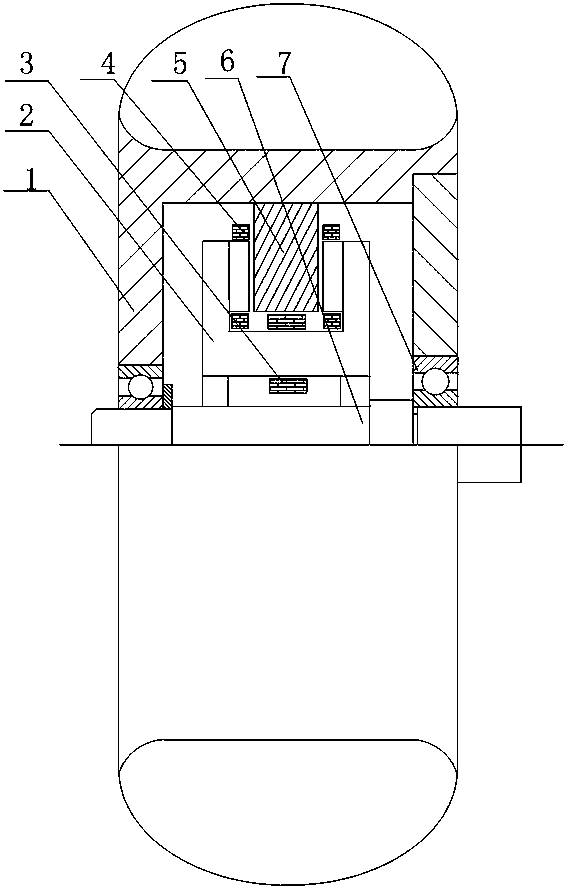

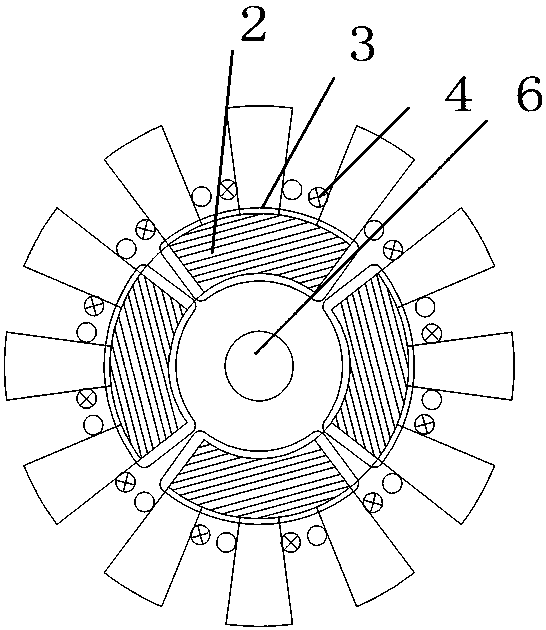

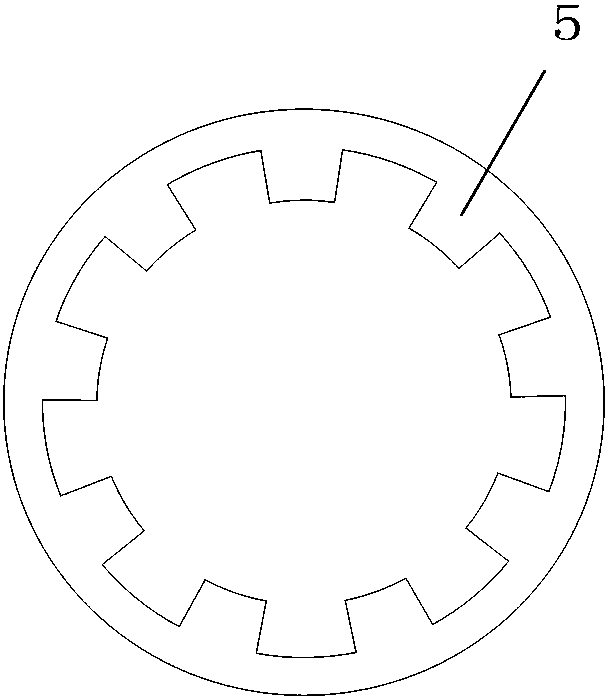

[0022] figure 1 It is a vertical sectional view of the direct drive wheel hub motor of the electric vehicle of the present invention. Among them, 1 hub, 2 stator cores, 3 excitation windings, 4 armature windings, 5 rotor cores, 6 shafts, and 7 bearings; electric vehicle direct drive hub motors are characterized in that: the hub is installed on the shaft through the bearing and can be wound around the shaft Rotation, the rotor core is fixed on the inner side of the circumference of the hub, and there are 9 rotor teeth extending toward the axis on the rotor core.

[0023] The stator core is fixed in the middle of the shaft. The stator core is composed of 4 evenly distributed "匚"-shaped stator cores. The yoke in the middle of the stator core is parallel to the axis; each stator core has three stator teeth at both ends. The sides of the teeth are fan-shaped; all the stator teeth are equally spaced and located on both sides of the rotor core in the axial direction; the stator core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com