Polypropylene-based sealing film for retort packaging and laminate using same

A technology for polypropylene and packaging, which is applied in the field of polypropylene-based sealing films for retort packaging and their laminates. It can solve the problems of undiscovered, unsatisfactory impact resistance, and insufficient low-temperature impact resistance, etc., and achieve sealing Excellent strength, good appearance, and excellent bending and whitening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

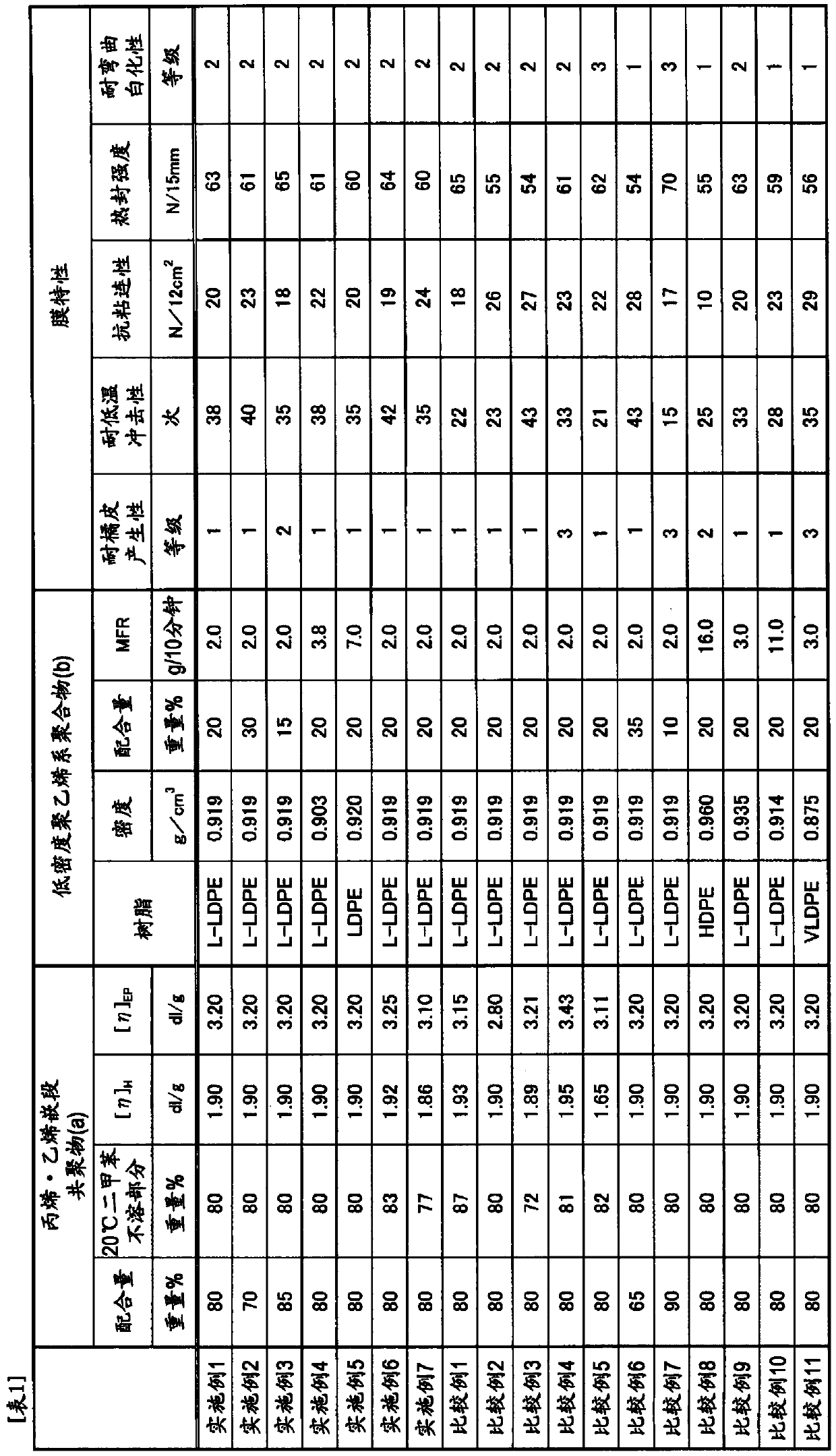

Examples

Embodiment 1

[0089] As the propylene-ethylene block copolymer (a) and the low-density polyethylene polymer (b), the following were used.

[0090] Propylene-Ethylene Block Copolymer (a)

[0091] Using the following propylene-ethylene block copolymer particles, wherein the content of 20°C xylene insoluble part is 80% by weight, the intrinsic viscosity ([η] H ) is 1.90dl / g, the content of 20 ℃ xylene soluble part is 20% by weight, and its intrinsic viscosity ([η] EP ) was 3.20 dl / g, MFR at 230° C. was 2.3 g / 10 minutes, and contained 300 ppm of “Sumilizer” GP as an antioxidant and 750 ppm of “Sumilizer” GS as an antioxidant.

[0092] Low-density polyethylene polymer (b)

[0093] The use density is 0.919g / cm 3 , MFR is 2.0 g / 10 minutes, and the copolymerization component is 1-hexene linear low-density polyethylene (hereinafter may be referred to as L-LDPE.) (Prime Polymer Co., Ltd. 2022L).

[0094]The above-mentioned (a) 80% by weight and (b) 20% by weight were mixed in a granular state wit...

Embodiment 2

[0096] A film with a thickness of 70 μm was obtained in the same manner as in Example 1, except that the mixing ratio of (a) and (b) used in Example 1 was changed to (a) 70% by weight and (b) 30% by weight. . The resulting film is particularly excellent in low-temperature impact resistance and orange peel resistance, and is also excellent in sealing strength, blocking resistance, and bending whitening resistance, and has sufficient performance for commercial large-scale retort applications. .

Embodiment 3

[0098] A film with a thickness of 70 μm was obtained in the same manner as in Example 1, except that the mixing ratio of (a) and (b) used in Example 1 was changed to (a) 85% by weight and (b) 15% by weight. . The orange peel resistance of the obtained film was slightly inferior, but it was at a level without problems, and it was excellent in low-temperature impact resistance, sealing strength, blocking resistance, and bending whitening resistance, and it had sufficient performance for commercial large-scale retort applications. membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com