Clutch device for a hybrid drive system

A clutch device and clutch technology, applied in fluid-driven clutches, mechanical-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as limited application range, poor micro-vibration isolation, and large restoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

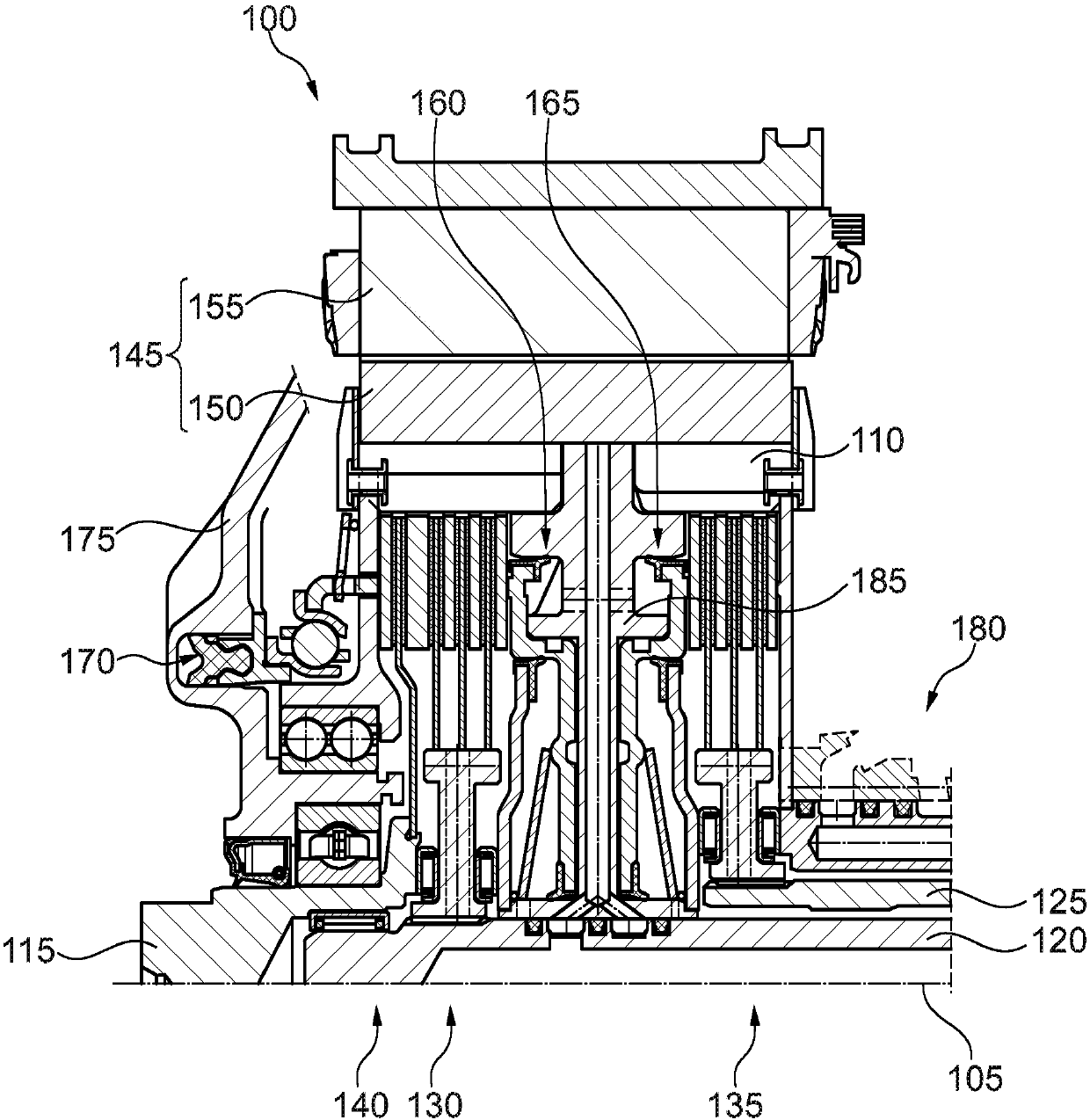

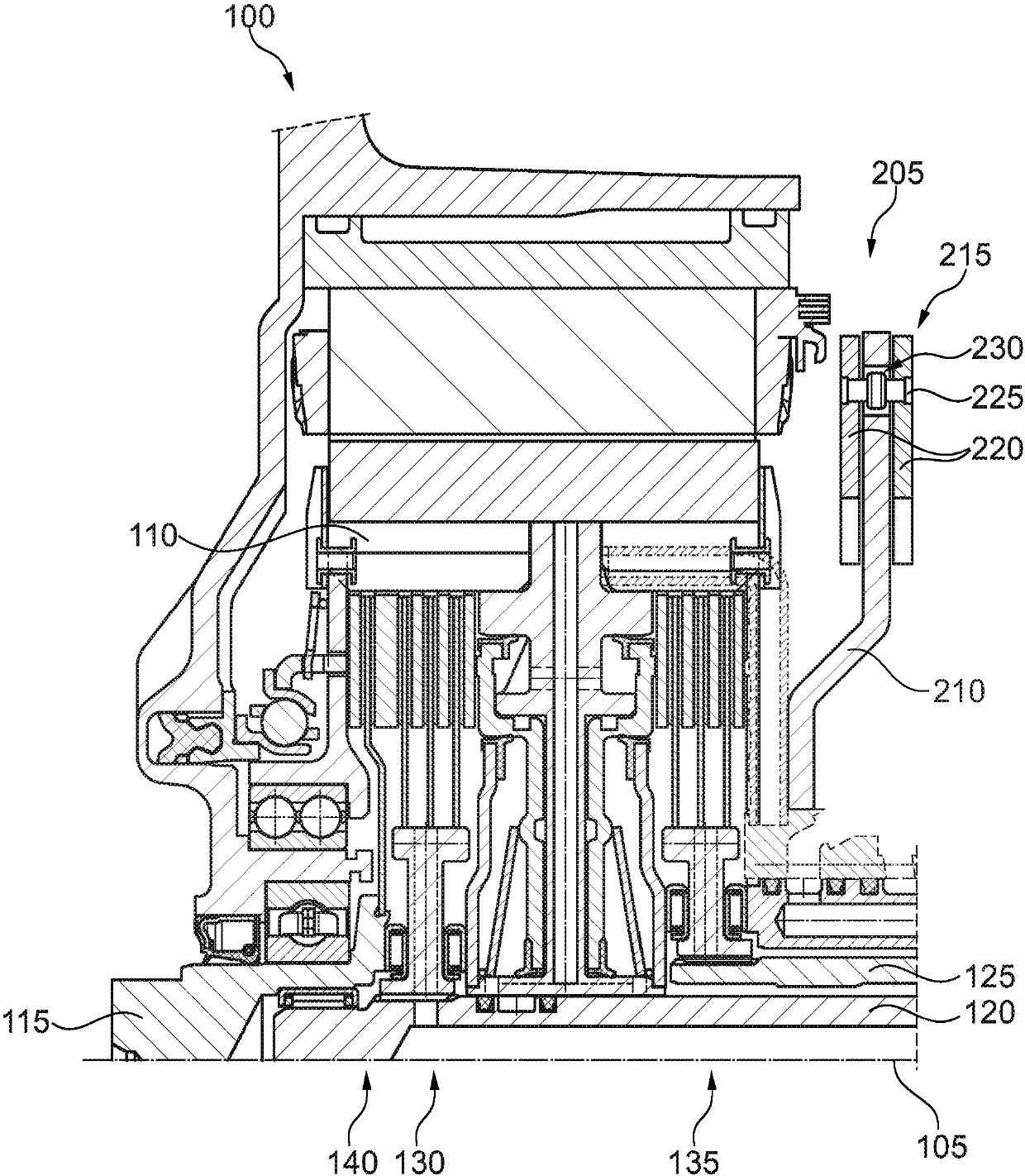

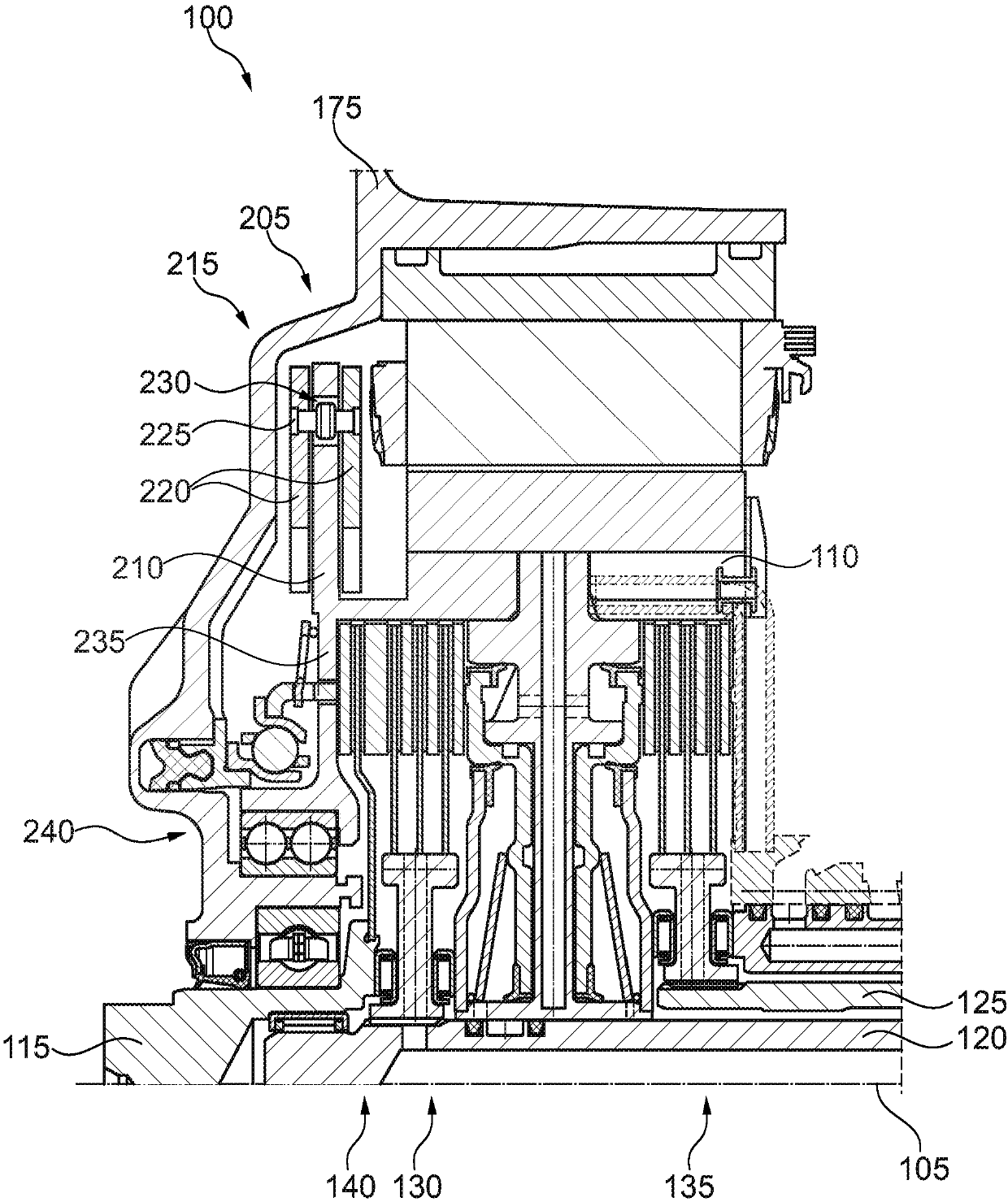

[0024] figure 1 An exemplary clutch arrangement 100 is shown. Arranged around the axis of rotation 105 is a first input 110 , a second input 115 , a first output 120 and a second output 125 .

[0025] A first clutch 130 is located between the first input 110 and the first output 120, a second clutch 135 is located between the first input 110 and the second output 125, and an optional third clutch 140 is located at the first input 110 and the second input terminal 115. The first and second clutches 130 and 135 are radially or preferably axially offset from one another and form an axial double clutch. The third clutch 140 is preferably axially offset from at least one of the first clutch 130 and the second clutch 135 .

[0026] The first input 110 is provided to be connected to an electric motor 145 which typically includes a rotor 150 and a stator 155 . The electric machine 145 is preferably of the inner rotor type, wherein the rotor 150 is located radially inward of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com