Drive device

A driving device, multi-driving technology, applied in the direction of output power conversion device, lamp testing, electrical components, etc., can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

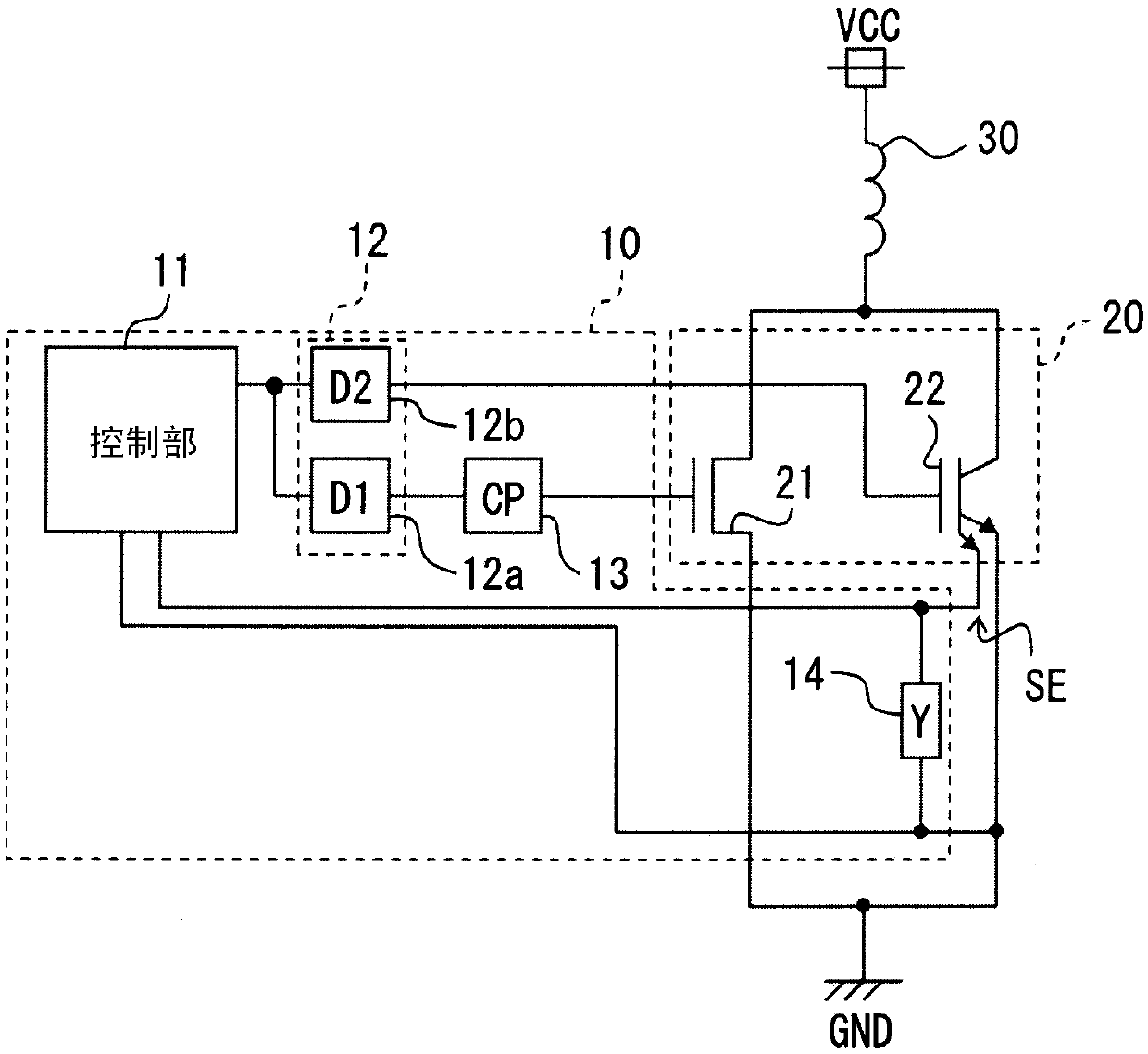

[0021] First, refer to figure 1 The schematic configuration of the drive device according to this embodiment will be described.

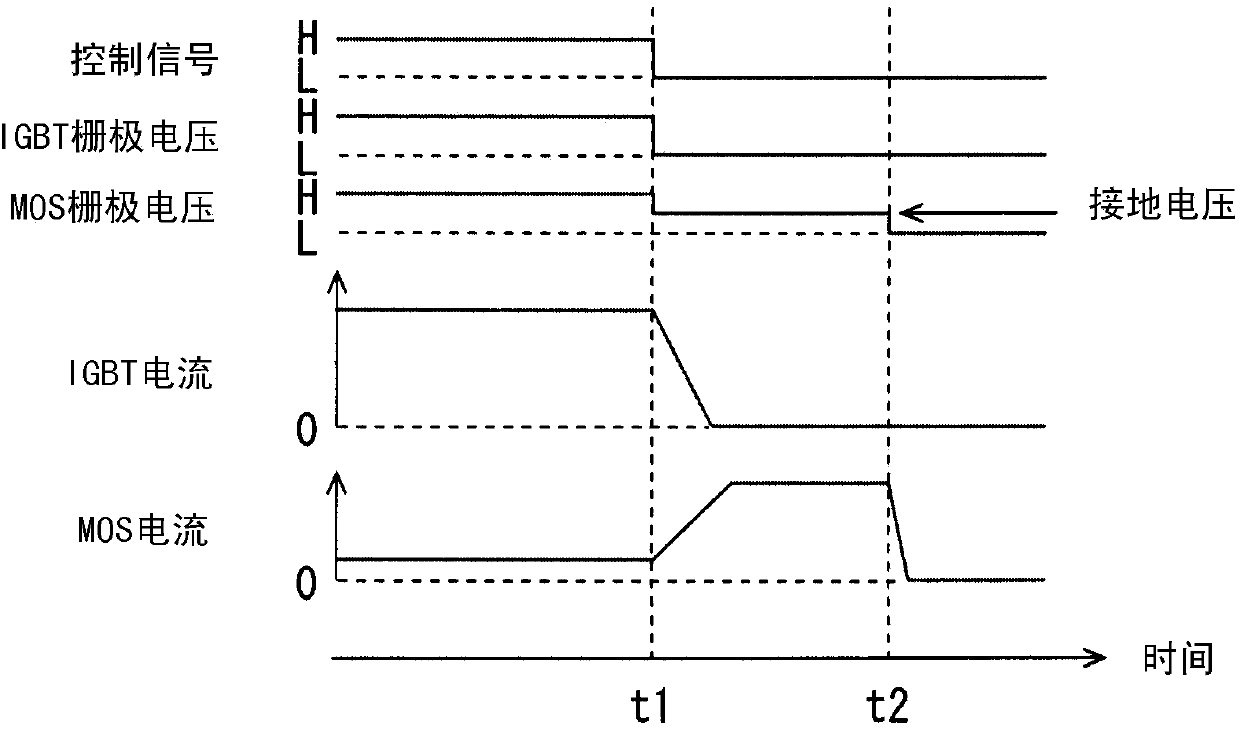

[0022] The drive device in this embodiment is used, for example, in a semiconductor device that obtains an output current by connecting two switching elements, a MOSFET and an IGBT, in parallel. An IGBT has a characteristic of generating a tail current when it is turned off. This tail current is the cause of increased switching loss at the time of shutdown. On the other hand, in a semiconductor device in which a MOSFET and an IGBT are connected in parallel, the power consumption due to the tail current is suppressed by making the timing of turning off the MOSFET later than that of the IGBT.

[0023] like figure 1 As shown, the driving device 10 in this embodiment is a device that supplies a gate voltage to the gates of the MOSFET 21 and the IGBT 22 connected in parallel between the main power supply VCC and the ground GND, and drives them. The M...

no. 2 approach

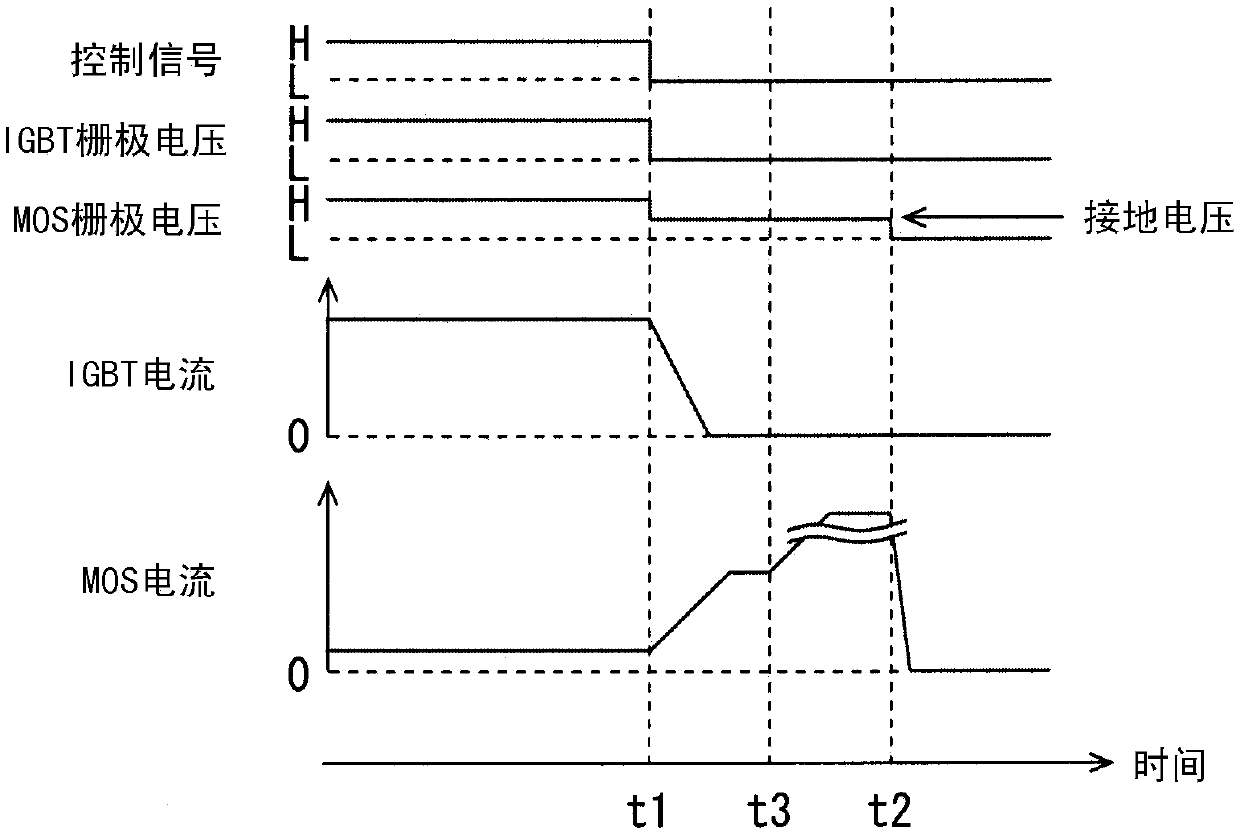

[0046] like Figure 4 As shown, the drive device 10 in this embodiment includes a gate voltage detection unit 15 ( Figure 4 GD). The configuration other than the gate voltage detection unit 15 is the same as that of the first embodiment, and thus detailed description thereof will be omitted.

[0047] The gate voltage detection unit 15 is connected to the gate of the IGBT 22 corresponding to the second switching element. The gate voltage detection unit 15 detects the gate voltage applied to the IGBT 22 by the second driver 12 b, and feeds back the value to the control unit 11 .

[0048] In the first embodiment, an example was described in which the control unit 11 sets the gate voltage of the MOSFET 21 as the clamp voltage on the condition that the control signal transitions from H to L as a trigger condition. However, the control unit 11 in this embodiment is based on The gate voltage of IGBT 22 detected by gate voltage detection unit 15 determines the gate voltage in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com