Prefabricated assembly type plant wall

A prefabricated assembly and plant wall technology, applied in the fields of botanical equipment and methods, building structure, container cultivation, etc., can solve the problems of unsuitable greening methods, wall damage, and single landscape effect, so as to beautify the surrounding environment of the building, realize the The effect of thermal insulation and air quality optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented under the technical premise of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

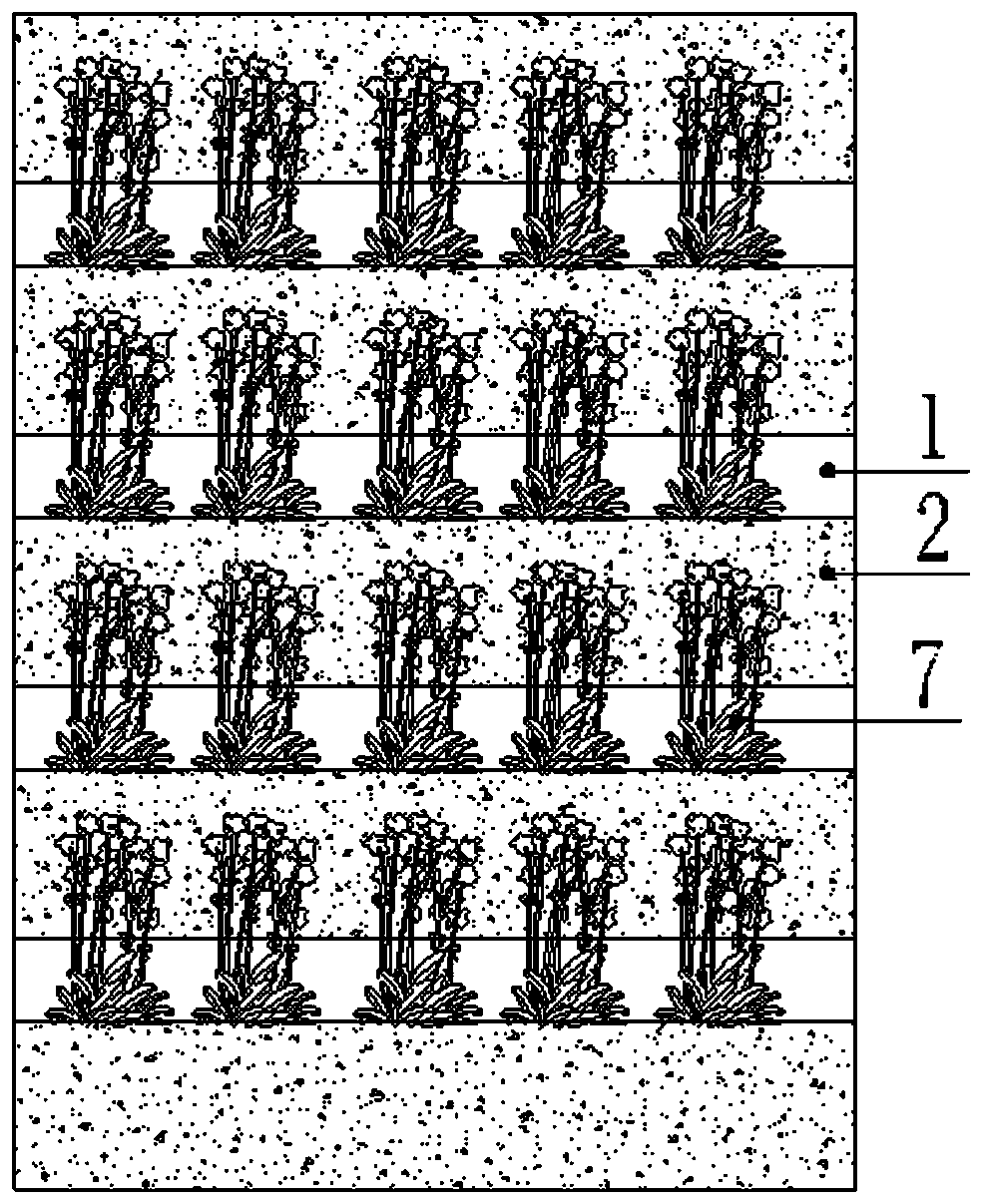

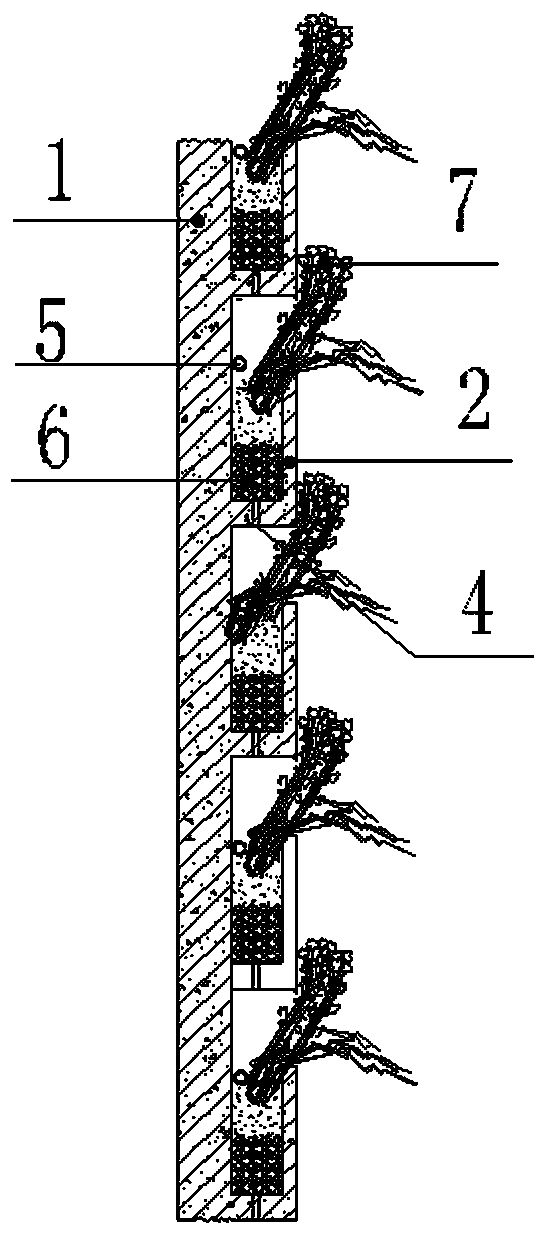

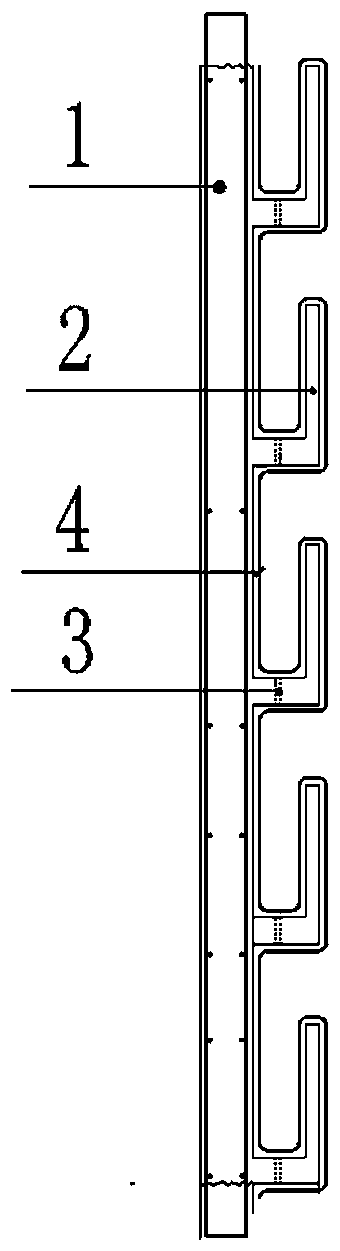

[0033] A prefabricated assembled plant wall, comprising a prefabricated assembled concrete wall 1, characterized in that a plant planting groove 2 is arranged on the outside of the prefabricated assembled concrete wall 1, and a drainage pipe 4 is pre-buried at the bottom of the plant planted groove, and the prefabricated assembled concrete wall After the wall 1 and the plant planting groove 2 are poured together, the waterproof membrane 3 is laid on the surface of the prefabricated concrete wall 1 and the plant planting groove 2 .

[0034] Such as image 3 and Figure 4 As shown, a kind of prefabricated assembled plant wall described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com