PLC (Programmable Logic Controller) control based feeding device for goose culture and method for preparing goose feed

A trough and material holding technology, which is applied in the field of feeding devices for goose breeding based on PLC control, can solve the problems of inability to automate operations, inability to feed geese, and low intelligence, so as to achieve strong market promotion value and improve immunity force, increase the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

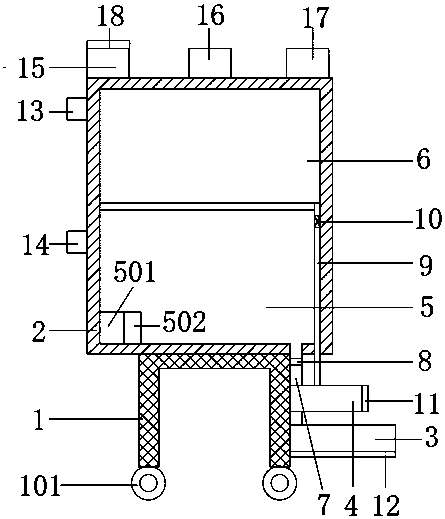

[0015] see figure 1 , the present invention provides a technical solution: a feeding device for goose breeding based on PLC control, including a support 1, a feed tank 3 and a water tank 4 are arranged on the right side of the support 1, and the water tank 4 is located above the feed tank 3 A water level monitor 11 is provided on the right side wall of the cavity of the water tank 4, a weight sensor 12 is provided at the bottom of the cavity of the trough 3, a housing 2 is provided on the top of the support 1, and the housing 2 The bottom of the inner cavity of the inner cavity is provided with a material containing box 5, and the top of the material containing box 5 is provided with a water tank 6, and the bottom right side of the described material containing box 5 is provided with a feeding pipe 7, and the top of the inner cavity of the feeding pipe 7 is provided with Control valve 8, a water delivery pipe 9 is provided on the right side of the bottom of the water tank 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com