Light artificial breast and preparation method thereof

A production method and technology of prosthetic breasts, which are applied in the direction of artificial breasts, etc., can solve the problems of increasing the cost of patients, insufficient shape, and rupture of TPU film, etc., and achieve the effect of good ventilation function, similar sense of reality, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

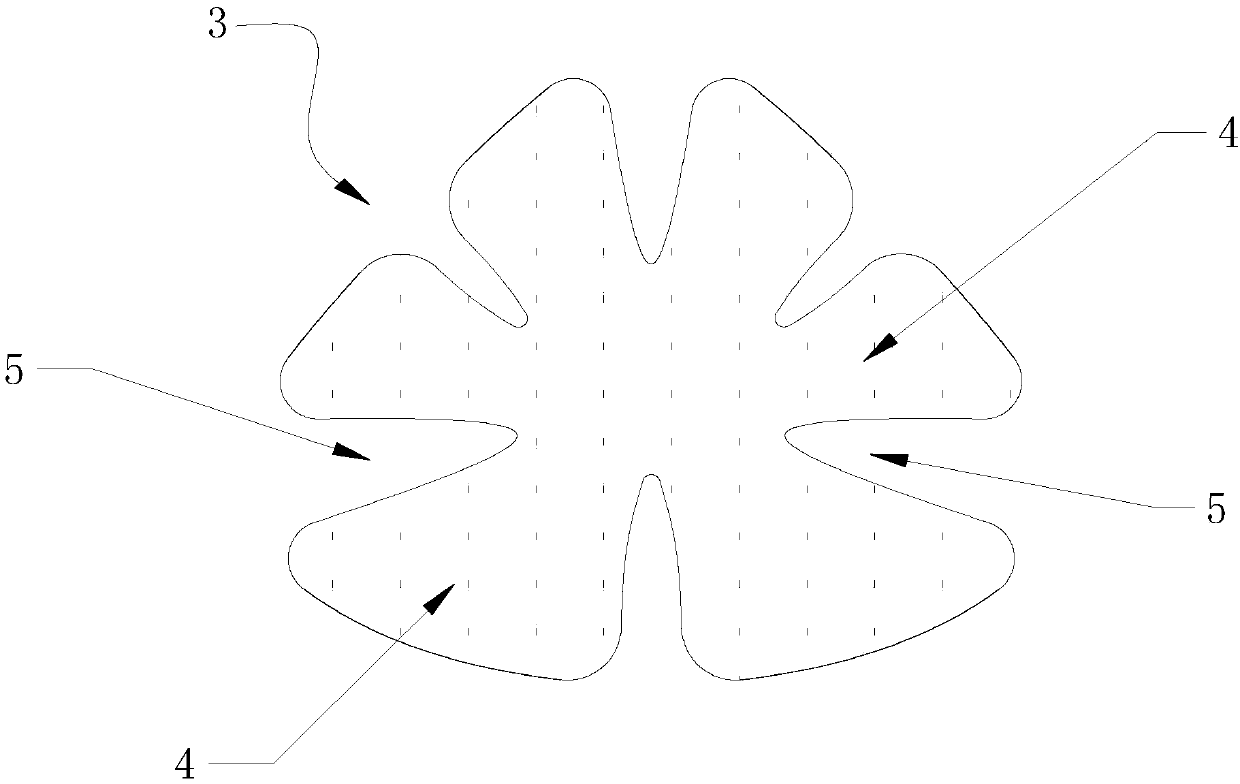

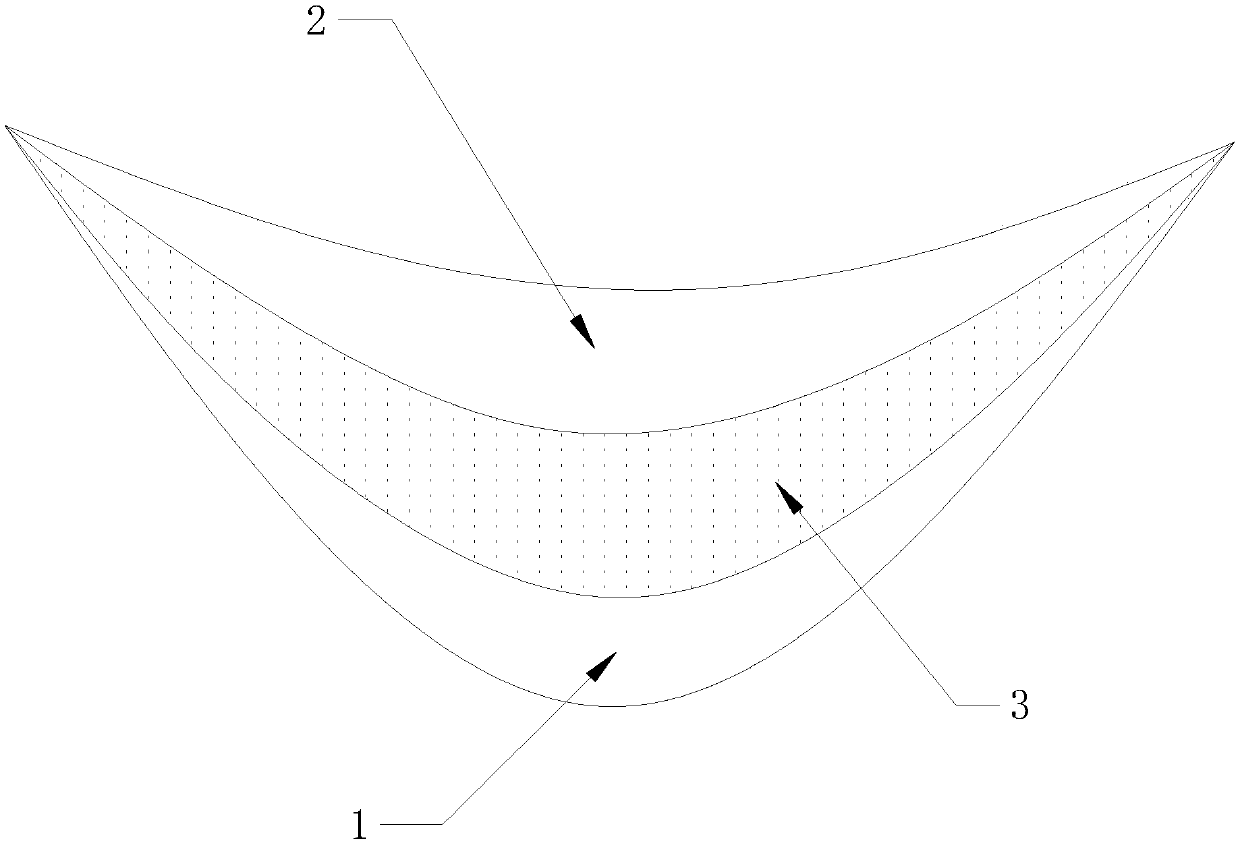

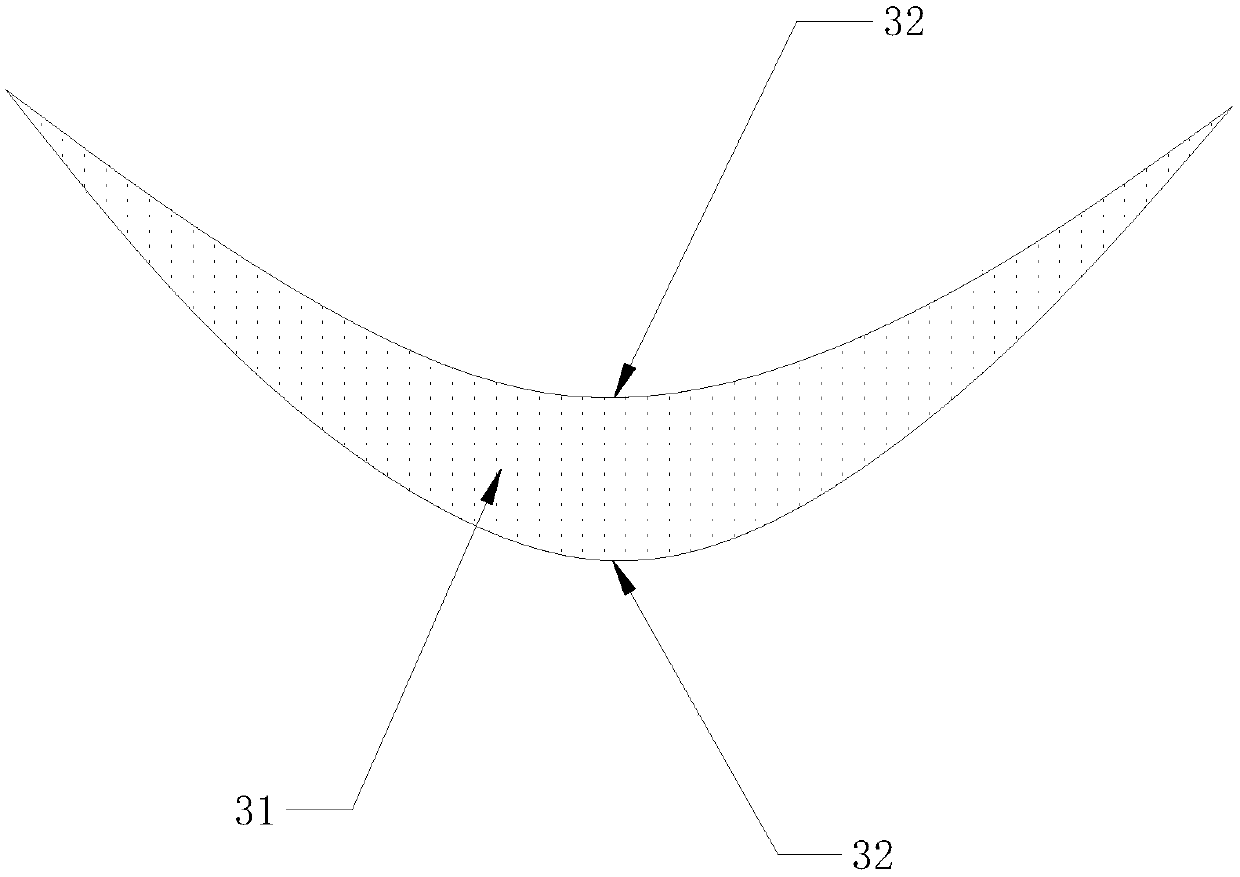

[0033] See attached Figure 1-4 , a kind of lightweight artificial milk of the present embodiment, comprises the silica gel layer 3 in the middle and the first upright cotton layer 1 and the second upright cotton layer 2 that are positioned at both sides of the silica gel layer 3, the silica gel layer 3 includes the gel that is positioned at the inside Layer 31 and polymer film 32 are located. In this embodiment, the polymer film is a polyurethane film, specifically a TPU film. The first upright cotton layer 1 is the upright cotton layer away from the body side, and the second upright cotton layer 2 is the upright cotton layer near the body side. The first upright cotton layer 1 includes an inner upright cotton layer 11 close to the silica gel layer 3 and an outer upright cotton layer 12 far away from the silica gel layer 3, and the textures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com