Blanking machine heat radiating device

A technology of heat sink and punching machine, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve the deformation and aging of punching head, the failure of punching equipment, and the impact of punching head and punching base on the precision of punching equipment. To achieve the effect of saving consumption and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

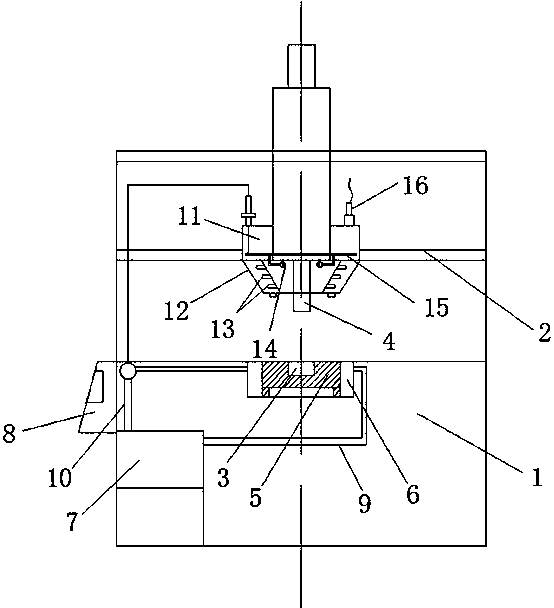

[0013] Embodiment 1: as figure 1 A punching machine heat dissipation device is shown, the heat dissipation device includes a punching head heat dissipation assembly, a base heat dissipation assembly and a cooling water storage tank 7, and the punching head heat dissipation assembly is installed on the fixed top of the punching head 4 On the bracket 2, the base heat dissipation assembly is composed of a heat dissipation connector 5 and a cooling water jacket 6. The heat dissipation connector 5 is covered on the punching groove 3 of the base 1, and the cooling water jacket 6 is coated on the outside of the heat dissipation connector 5. The punching head heat dissipation assembly includes a fixed jacket 11, a water transfer ring pipe 15 and a water mist nozzle 14. The water mist nozzle 14 is connected to the water transfer ring pipe 15 Above, the water mist nozzles 14 are symmetrically installed on both sides of the punching head 4 , and the cooling water storage tank 7 is connec...

Embodiment 2

[0014] Embodiment 2: as figure 1 As shown, an annular interlayer 12 is provided below the fixed jacket 11, and the interlayer 12 is a tapered structure with a small diameter in the lower part and a large diameter in the upper part; Fog, so that water mist gathers on the punching head 4, to avoid the spread of water mist.

Embodiment 3

[0015] Embodiment 3: as figure 1 As shown, the inner side of the interlayer 12 is evenly distributed with a plurality of air injection ports 13, the bottom of the interlayer 12 is provided with two external air injection ports, and the top of the fixed jacket 11 is provided with an air pressure pipeline 16, and the air pressure pipe The road 16 is connected to the air injection port 13 and the external air injection port, and the air pressure line 16 is connected to the air pump; the interlayer 12 can not only be used to gather water mist, but also can dry the surface of the punching head 4 through the jet air flow, and absorb the heat. The water mist is blown out of the jacket through the air flow to avoid the accumulation of water mist, which is more conducive to the drying of the punching head 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com