Gas flotation high-speed motorized spindle

A high-speed electric spindle and air-floating technology, which is applied to large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems that the air-floating spindle cannot meet, and achieve strong adaptability and practicability. The effect of bearing capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

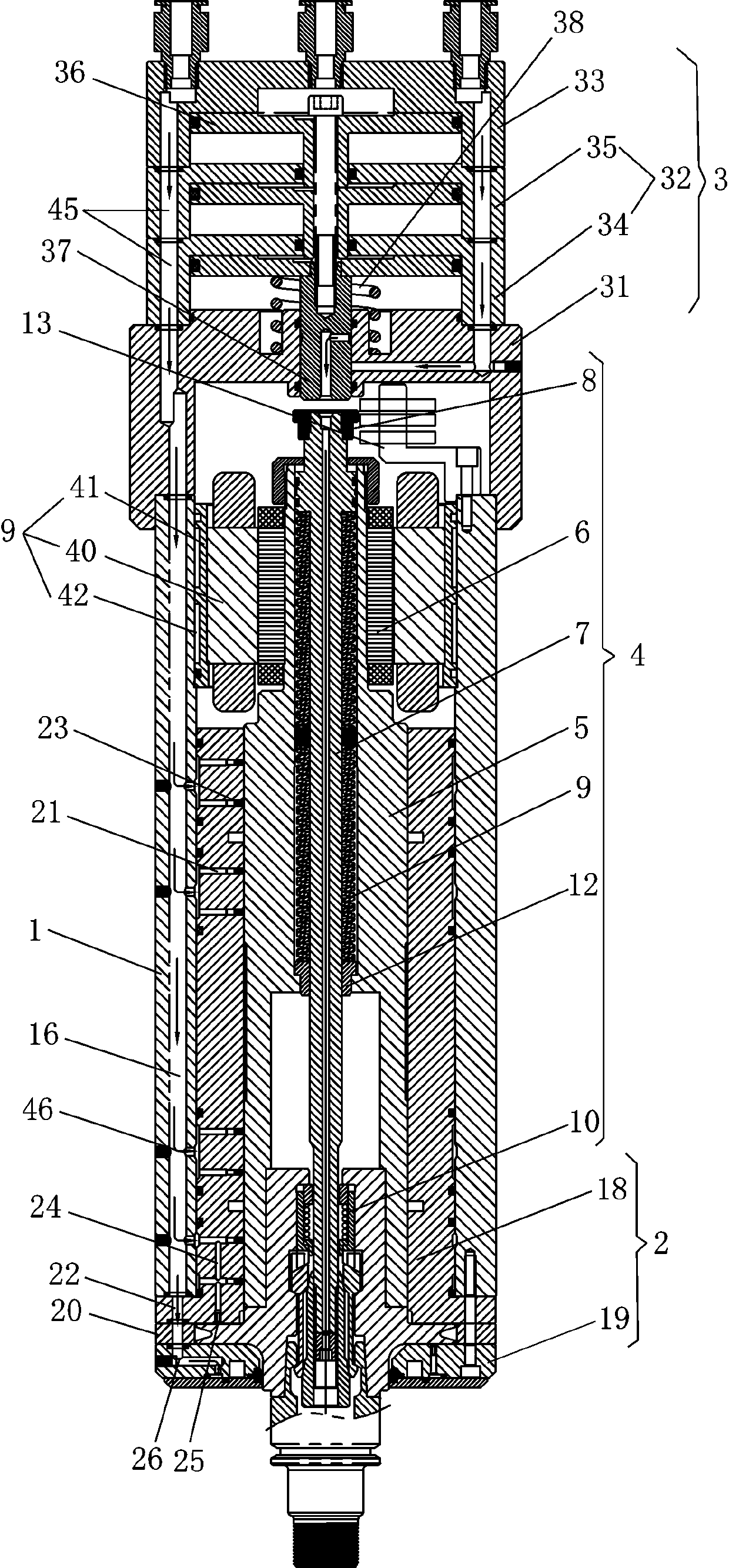

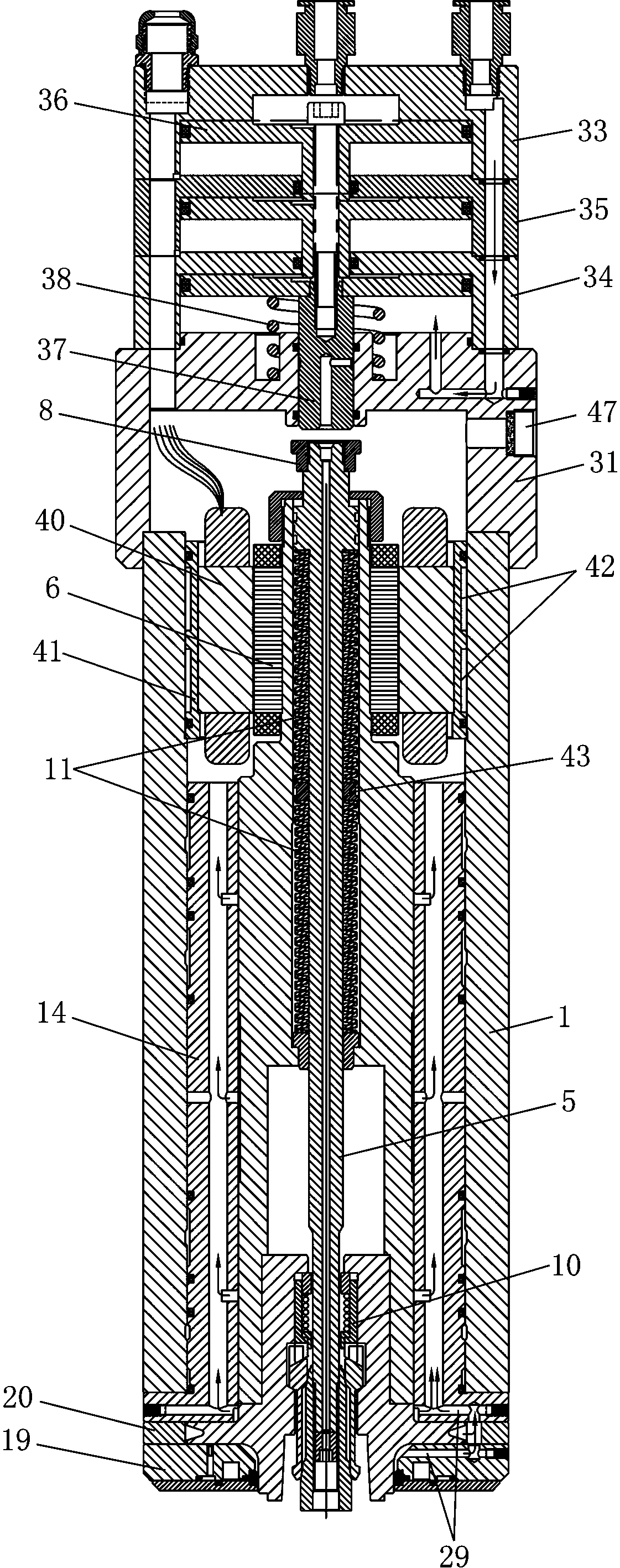

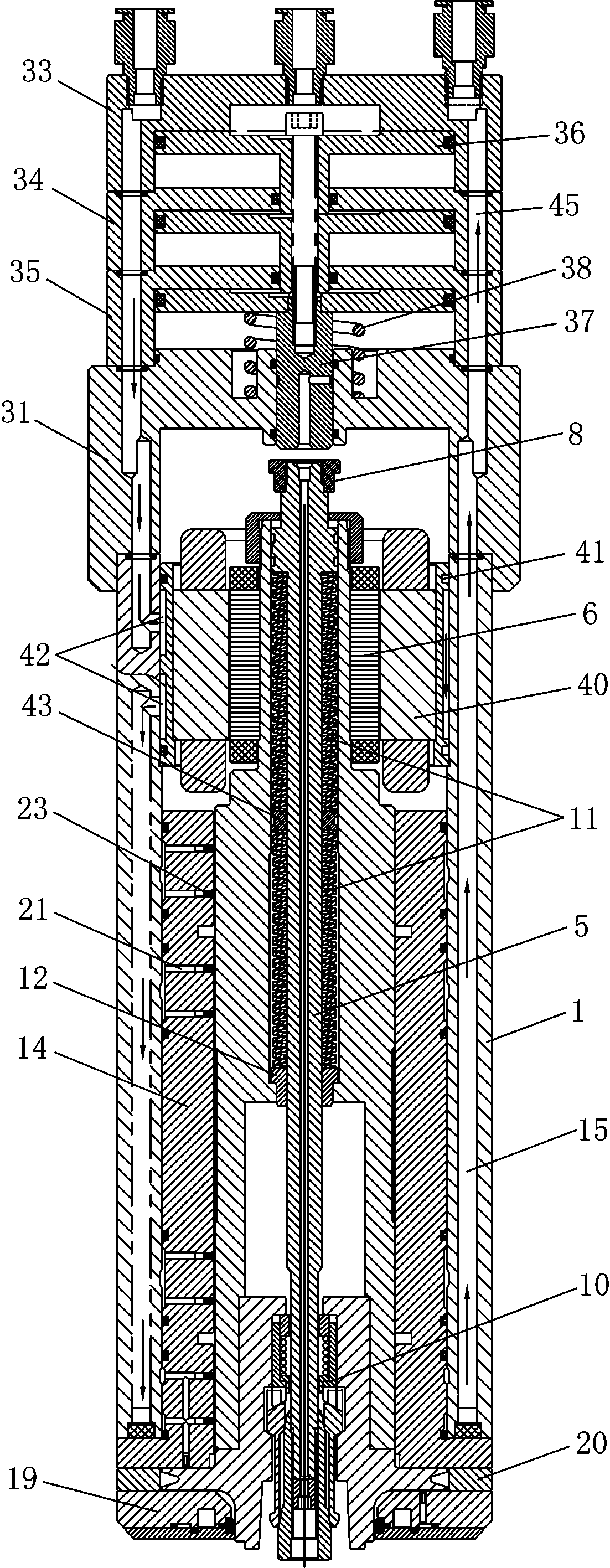

[0028] Such as Figure 1-10 As shown, an air-floating high-speed electric spindle includes a housing main body 1, a bearing mechanism 2, a cylinder mechanism 3, and a rotor mechanism 4. The bearing mechanism 2 and the rotor mechanism 4 are respectively installed in the housing main body 1. The cylinder mechanism 3 is installed on the top of the housing main body 1, and is connected to the rotor mechanism 4 in a transmission manner. The rotor mechanism 4 includes a shaft core 5, a rotor 6, a pull rod 7, a pull rod induction nut 8, an elastic component 9 and Pull claw assembly 10, the rotor 6 is mounted on the end of the shaft core 5, the pull rod 7 is slidably arranged in the shaft core 5, and the pull rod induction nut 8 is set on the top end of the pull rod 7 , the claw assembly 10 is arranged at the bottom end of the pull rod 7, the elastic assembly 9 is composed of several helical disc springs 11, and several of the helical disc springs 11 are sleeved on the pull rod 7 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com