Wood plate polishing machine

A polishing machine, wood board technology, applied in grinding/polishing equipment, grinding/polishing safety device, grinding frame, etc., can solve the problem of easy deviation of the correct feed direction, time-consuming and labor-intensive, affecting the normal processing, etc. problems, to ensure the appearance quality, flexible operation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

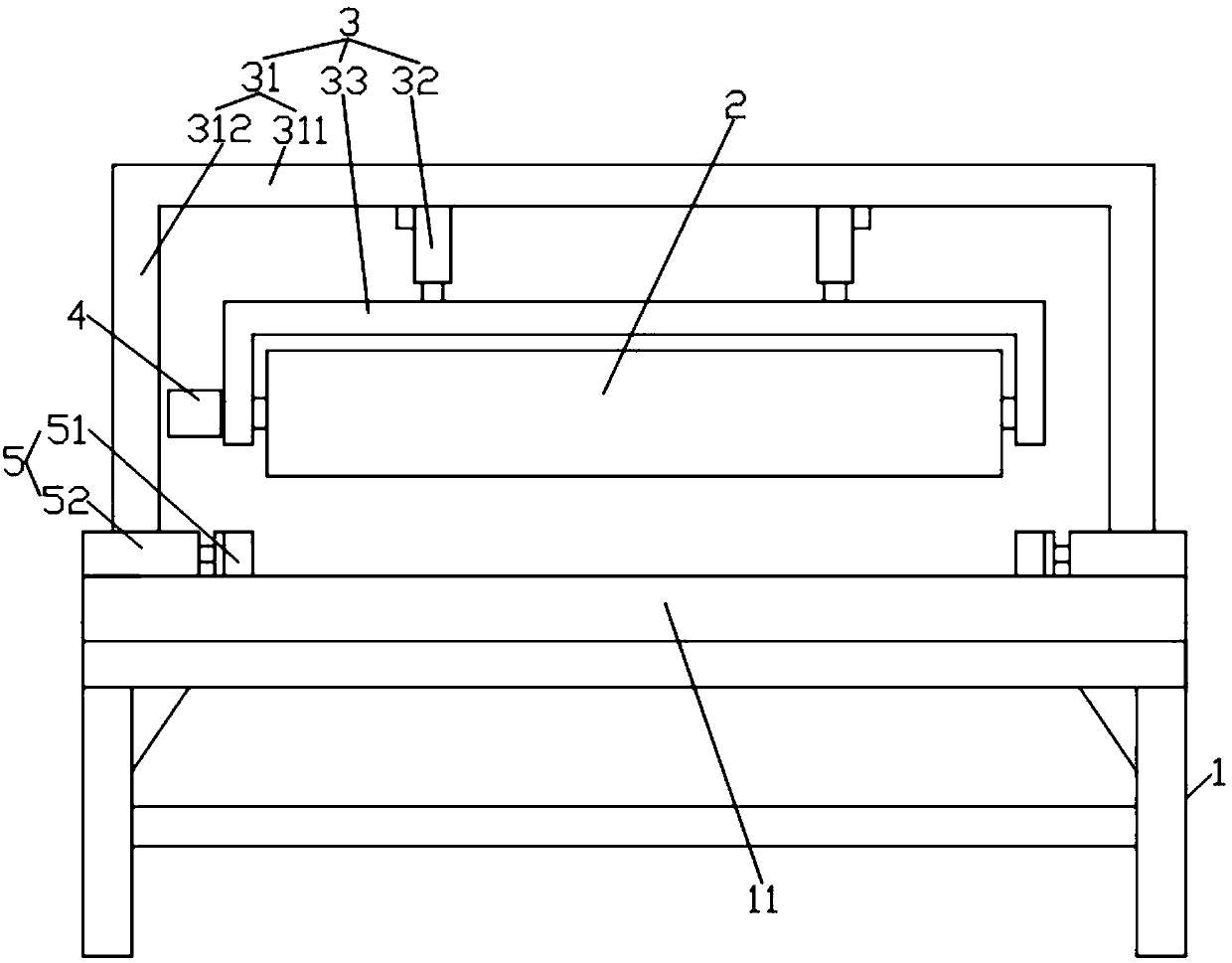

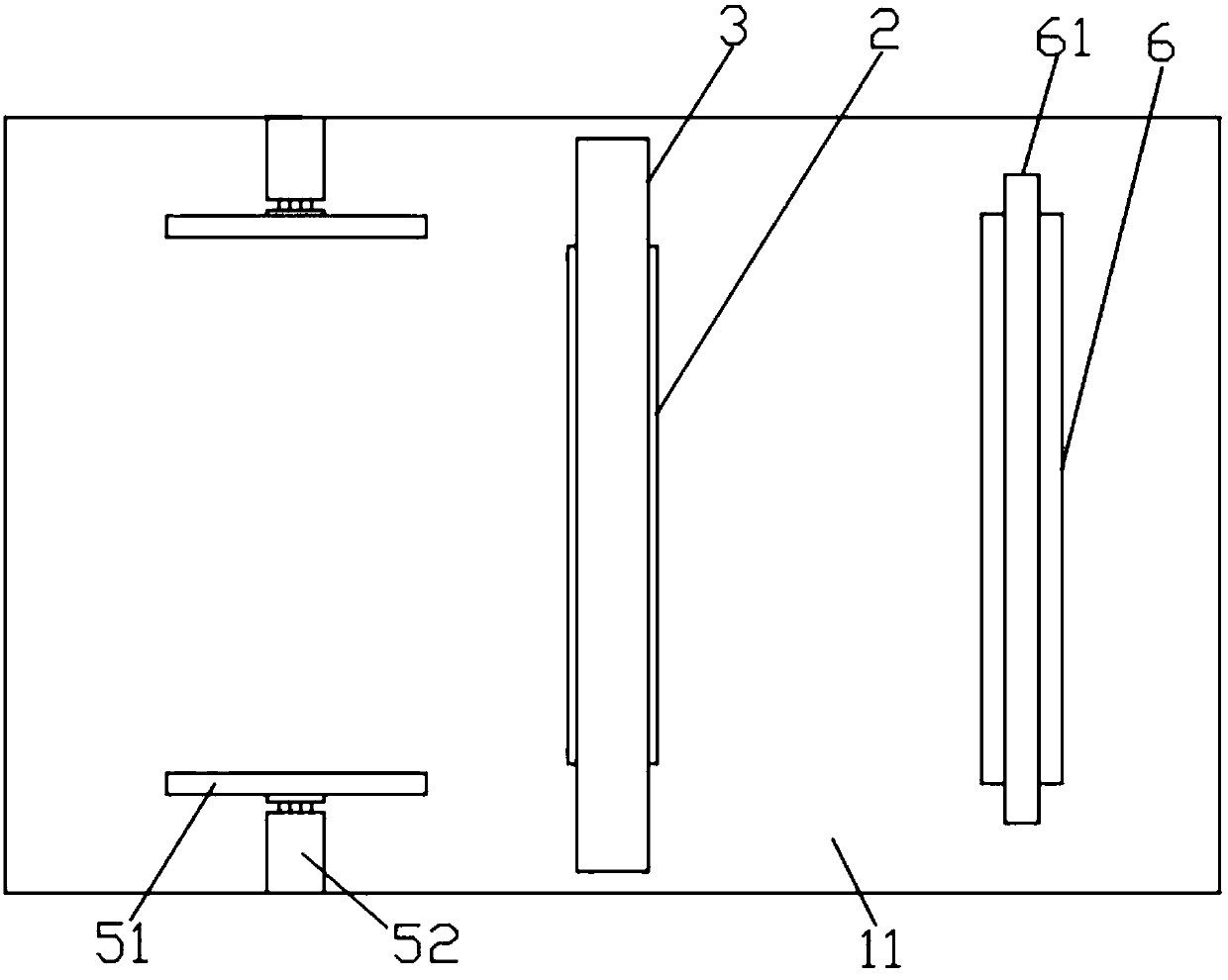

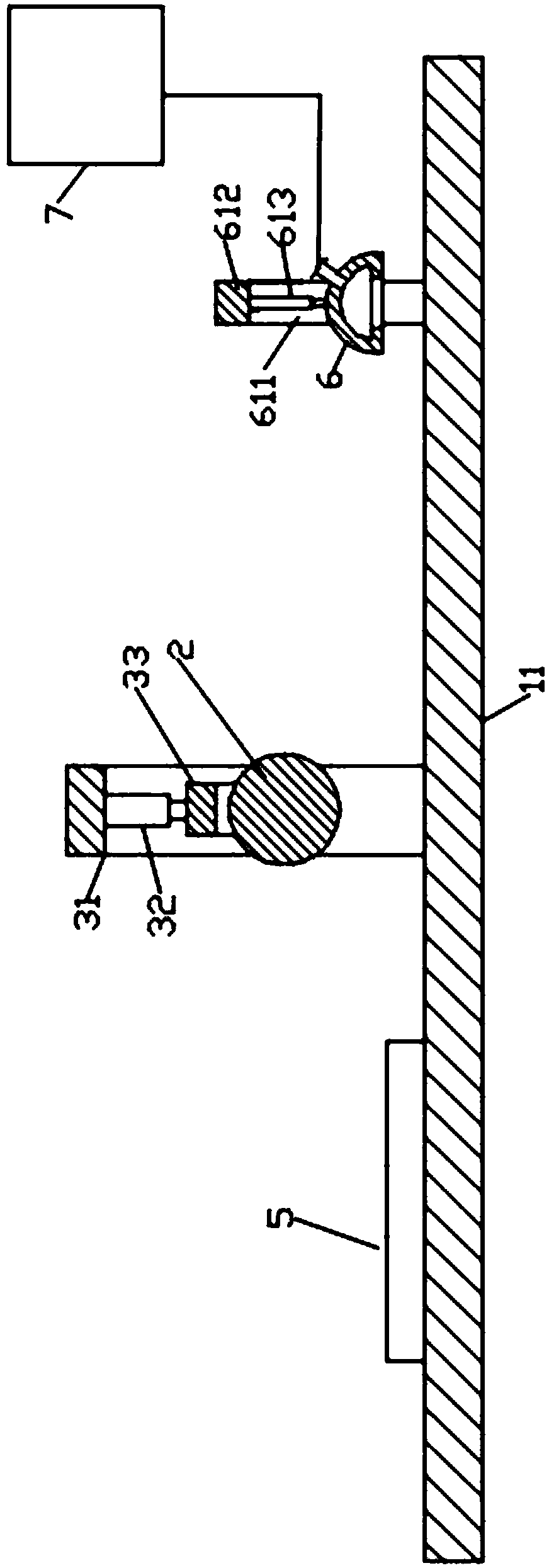

[0044] Example: such as Figures 1 to 3 As shown, the wood polishing machine of this embodiment includes a bracket 1, a sanding roller 2, a lifting mechanism 3, a driving mechanism 4, a limit guide mechanism 5 and a dust removal mechanism 6;

[0045] The upper end of the above-mentioned support 1 has a rectangular processing table 11 arranged horizontally;

[0046] The above-mentioned sanding roller 2 is horizontally arranged above the middle part of the above-mentioned processing table 11, and its two ends are respectively rotatably connected with the above-mentioned lifting mechanism 3, and the above-mentioned lifting mechanism 3 can drive the above-mentioned grinding roller 2 to move up and down to approach or move away from the above-mentioned processing table 11;

[0047] The above-mentioned driving mechanism 4 is in transmission connection with the above-mentioned sanding roller 2, and is used to drive the above-mentioned sanding roller 2 to rotate;

[0048] The above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com